A smelting short net

A short network and main row technology, applied in the field of ore smelting, can solve the problems of large power consumption, power waste, low utilization efficiency of transformers, etc., and achieve the effect of reducing reactance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

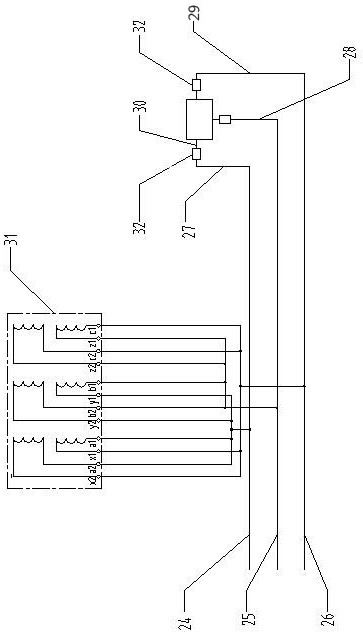

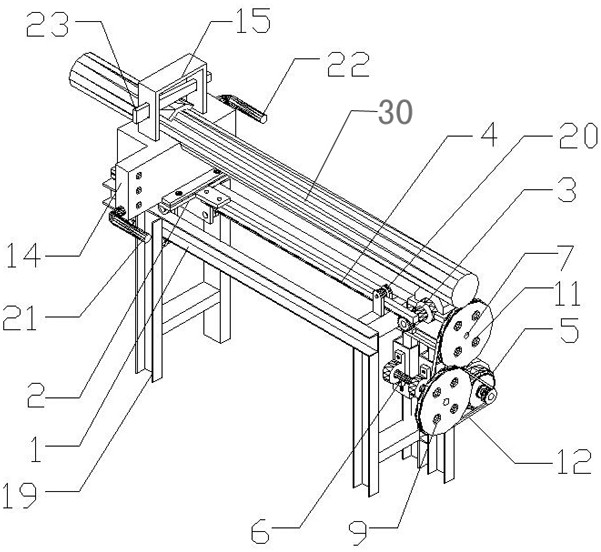

[0023] like Figure 1 to Figure 6 As shown, a short smelting net includes a first main row 24, a second main row 25, a third main row 26, and a corresponding connection with the first main row 24, the second main row 25, and the third main row 26 respectively. The first branch row 27 , the second branch row 28 and the third branch row 29 are provided with electrode rods 30 on the first branch row 27 , the second branch row 28 and the third branch row 29 . The first main row 24 , the second main row 25 and the third main row 26 are arranged parallel to each other, the second main row 25 is located below the first main row 24 and the third main row 26 and the first main row 24, the second main row 25 and the third main row The distances between the rows 26 are equal to each other; the first row 27, the second row 28 and the third row 29 are respectively connected with the electrode rod 30 through the electrode pushing device 32; the electrode pushing device 32 includes a linear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com