Catalyst for cathode in fuel cell

A fuel cell cathode and catalyst technology, applied in fuel cells, solid electrolyte fuel cells, battery electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

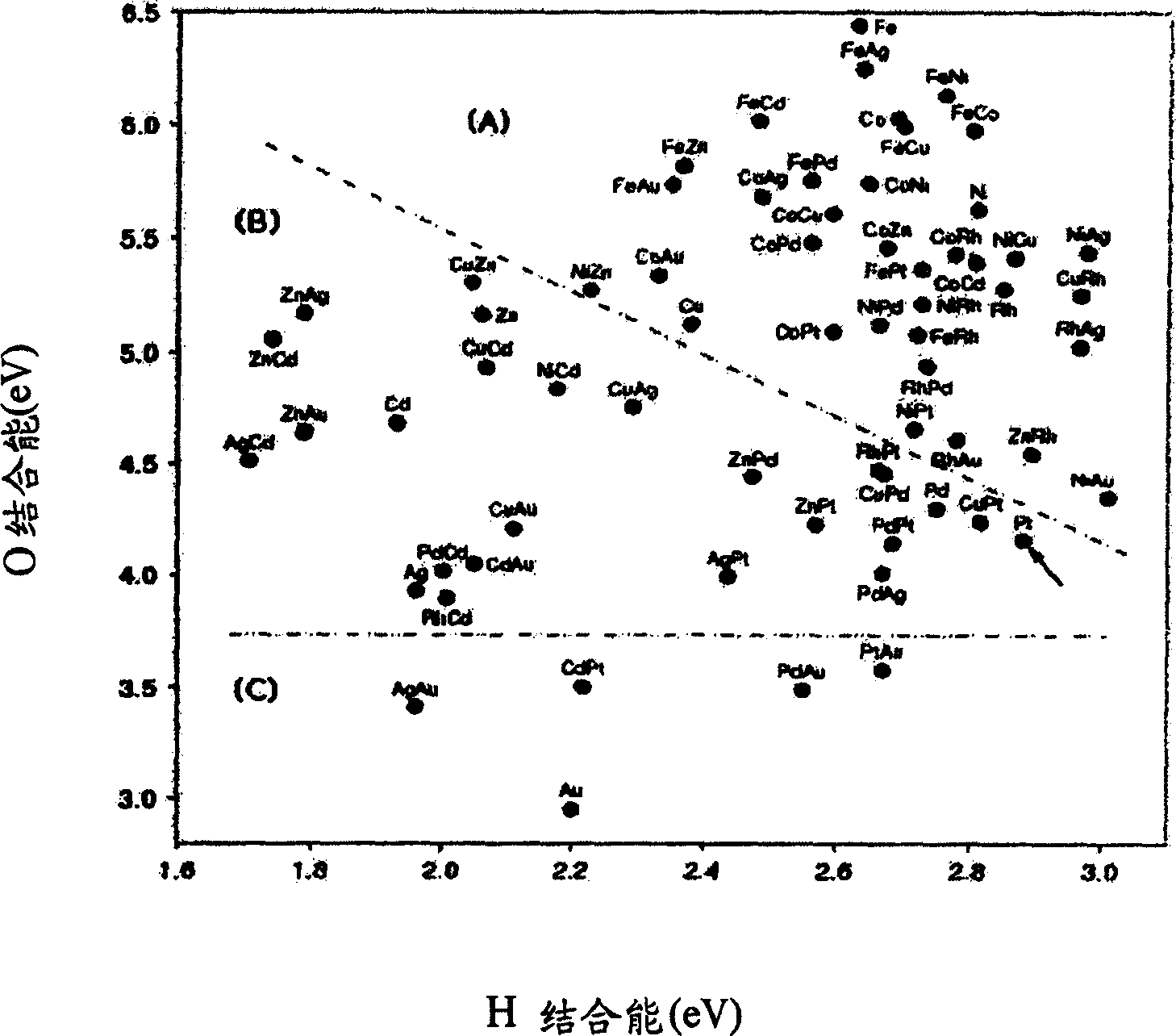

[0026] In a direct methanol fuel cell (DMFC), the catalyst used for the cathode must have low methanol oxidation reactivity and high oxygen reduction reactivity.

[0027] For the methanol oxidation reaction, the methanol (CH 3 OH) has gone through the reaction steps represented by the following reaction scheme 1:

[0028] Process 1

[0029]

[0030] According to reports, CH 3 The decomposition reaction of O is the rate-determining step in reaction scheme 1 [M. Mavrikakis and M.A. Barteau, J. of Molecular Catalysis A, 131, 135 (1998)]. CH 3 The decomposition temperature of O rises as the binding force between catalyst particles and oxygen increases or as the binding force between catalyst particles and hydrogen decreases [M.A.Barteau, Catal.Lett.8, 175(1991)].

[0031] To reduce the methanol oxidation reactivity of catalyst particles, a high CH 3 O decomposition temperature. In this regard, it is advantageous to increase the binding capacity of the catalyst particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com