Longitudinal laying direct laying outer wall construction structure and start hardware member used therefor and intermediate drip channel

A technology of middle drops and hardware, applied in building construction, covering/lining, construction, etc., can solve problems such as deterioration and corrosion, and achieve the effects of excellent water resistance, excellent load resistance and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

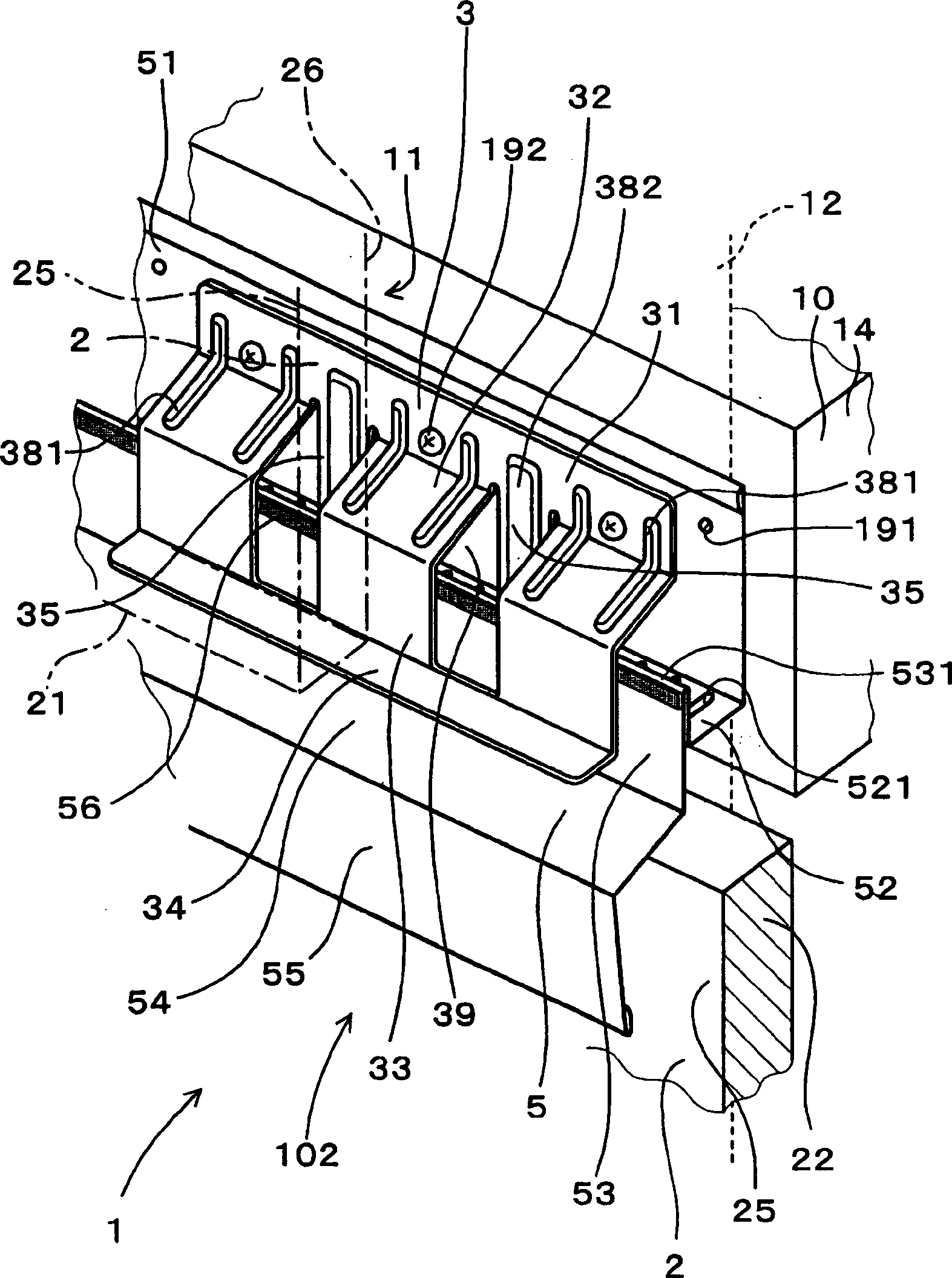

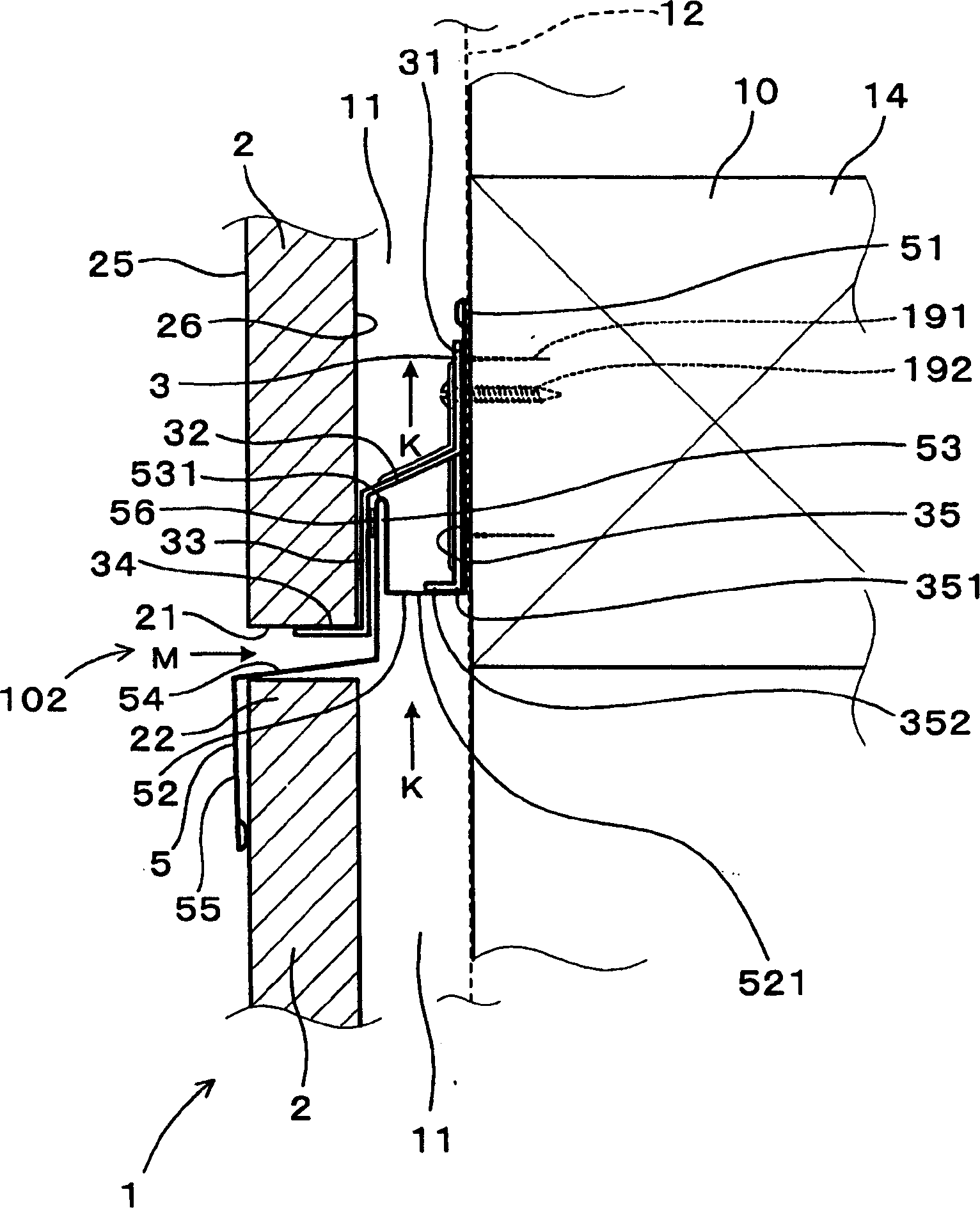

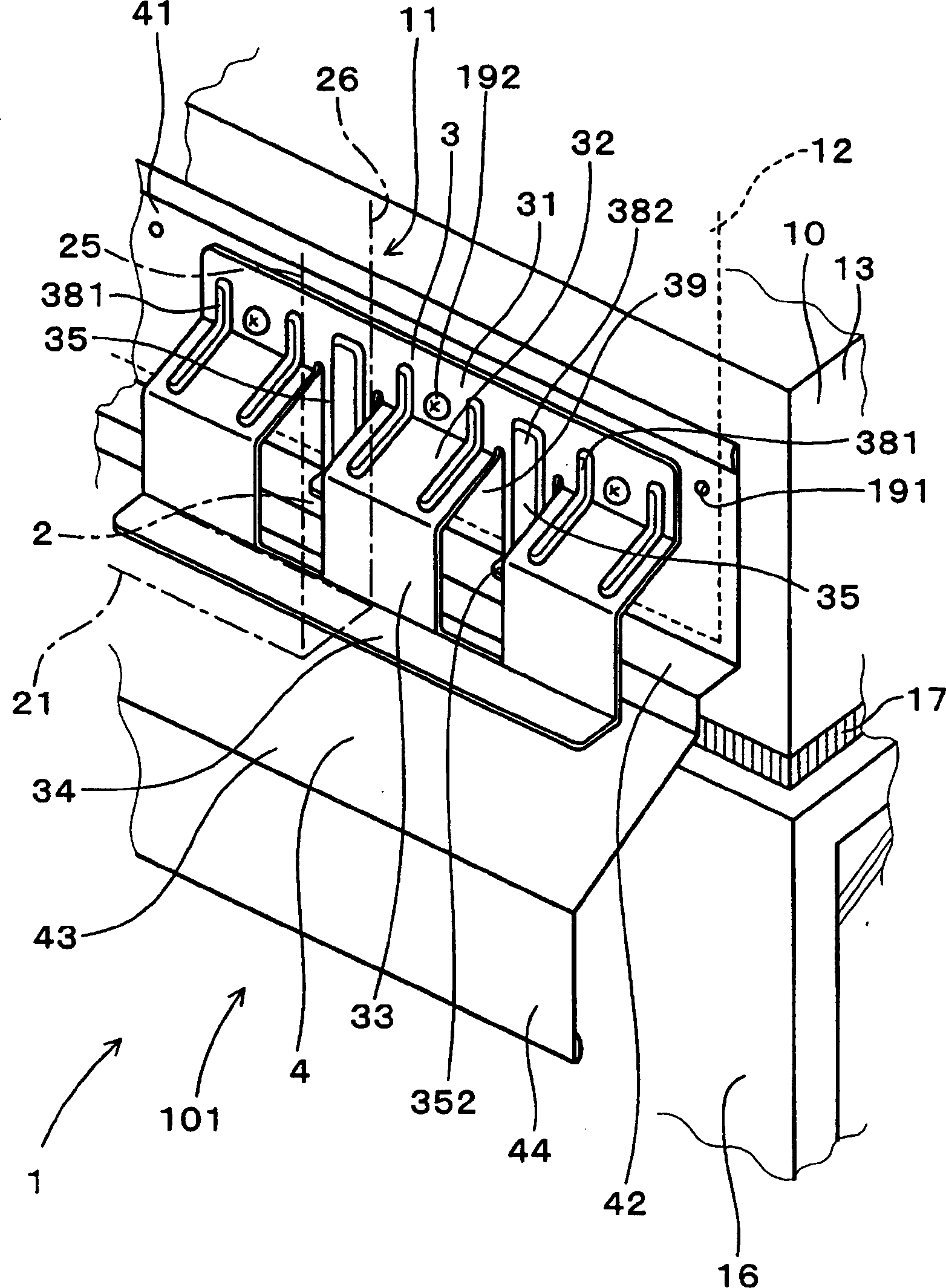

[0100] use Figure 1 to Figure 13 , with regard to the vertical laying and direct laying of the outer wall construction structure of the embodiment of the present invention, as well as the used starting hardware and the middle dripping tank, it will be described.

[0101] The above-mentioned vertical laying directly lays the outer wall construction structure 1 such as Figure 1 to Figure 5 As shown, the outer wall panel 2 is directly installed and fixed on the structural main body 10 of the building of a multi-storey building with its length direction as the up and down direction.

[0102] Such as figure 1 , figure 2 As shown, on the middle part 102 between the upper and lower adjacent floors (for example, 1st floor and 2nd floor) in the above-mentioned building, the starting hardware 3 and the middle drip tank 5 are arranged. The above starting hardware 3 supports the lower end 21 of the upper outer wall panel 2 . In addition, the above-mentioned middle drip groove 5 di...

Embodiment 2

[0154] This example Figure 14 , Figure 15 As shown, with respect to the starting hardware 3 of the present invention shown in Example 1, the measurement of the load resistance strength relative to the weight of the outer wall plate is an example for comparison with the starting hardware 93 shown in the conventional example. .

[0155] As the starting hardware 3 of embodiment 1, use height h=40mm, front and rear width d=24mm, the starting hardware of left and right width w=150mm (refer to Figure 8 , Figure 9 ).

[0156] On the other hand, the starting hardware 93 of the conventional example has a height of 40 mm, a front-back width of 27 mm, and a cross-section of a left-right width of 150 mm, which is substantially L-shaped.

[0157] Each starting hardware was formed by bending a 1.2 mm thick stainless steel plate (SUS304).

[0158] During the test, if Figure 14As shown, firstly, the starting hardware 3 as the test material and the basic drip tank 4 are fixed on a C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com