Method for producing rotor

A manufacturing method and rotor technology, which are used in rotary piston/swing piston pump components, rotary piston pumps, rotary piston machines, etc. Defect and high problems, to achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 approach

[0188] Figures 21 to 26 The figure which shows the rotor material (1) obtained by the forging process of 2nd Embodiment of this invention. As shown in the above figure, in the second embodiment, the rotor blank (1) is composed of the rotor part (2) and the rest parts (5), (6), and the rotor part (2) does not include the rest part (5). ), (6).

[0189] The remaining material parts (5), (6) are provided so as to protrude from the one end surface (2a) of the rotor part (2) to the one end side.

[0190] In addition, in the rotor blank (1) of this embodiment, the one end surface (3a) of the central hole (3) does not reach the inside of the remaining material part (5), and the one end surface (3a) is arranged at a lower position than the one end surface (3a) of the rotor part (2). 2a) More medial.

[0191] In addition, the one end surface (4a) of the vane groove (4) also does not reach the inside of the residual material part (6), and the one end surface (4a) is arranged on the ...

Embodiment 1

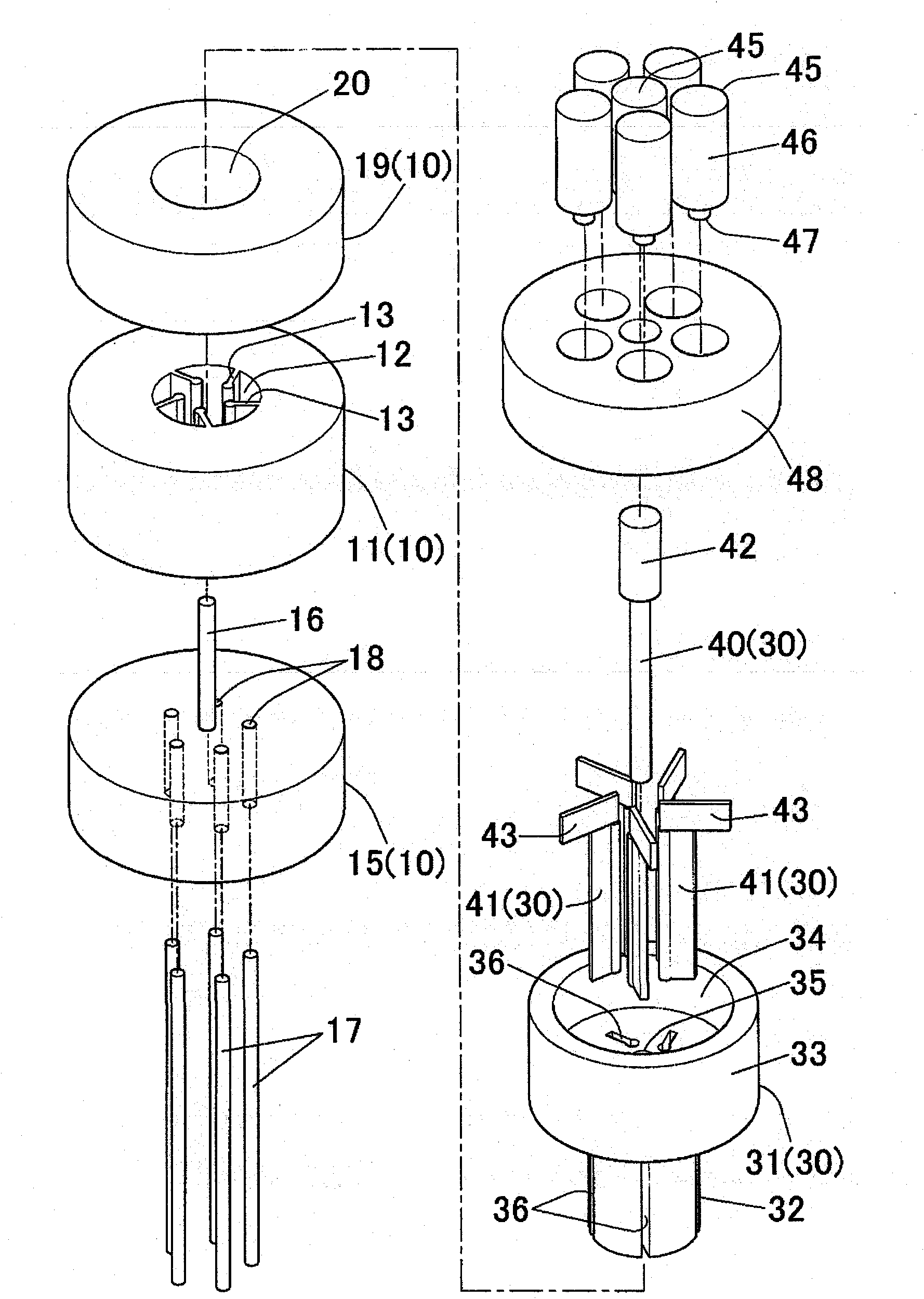

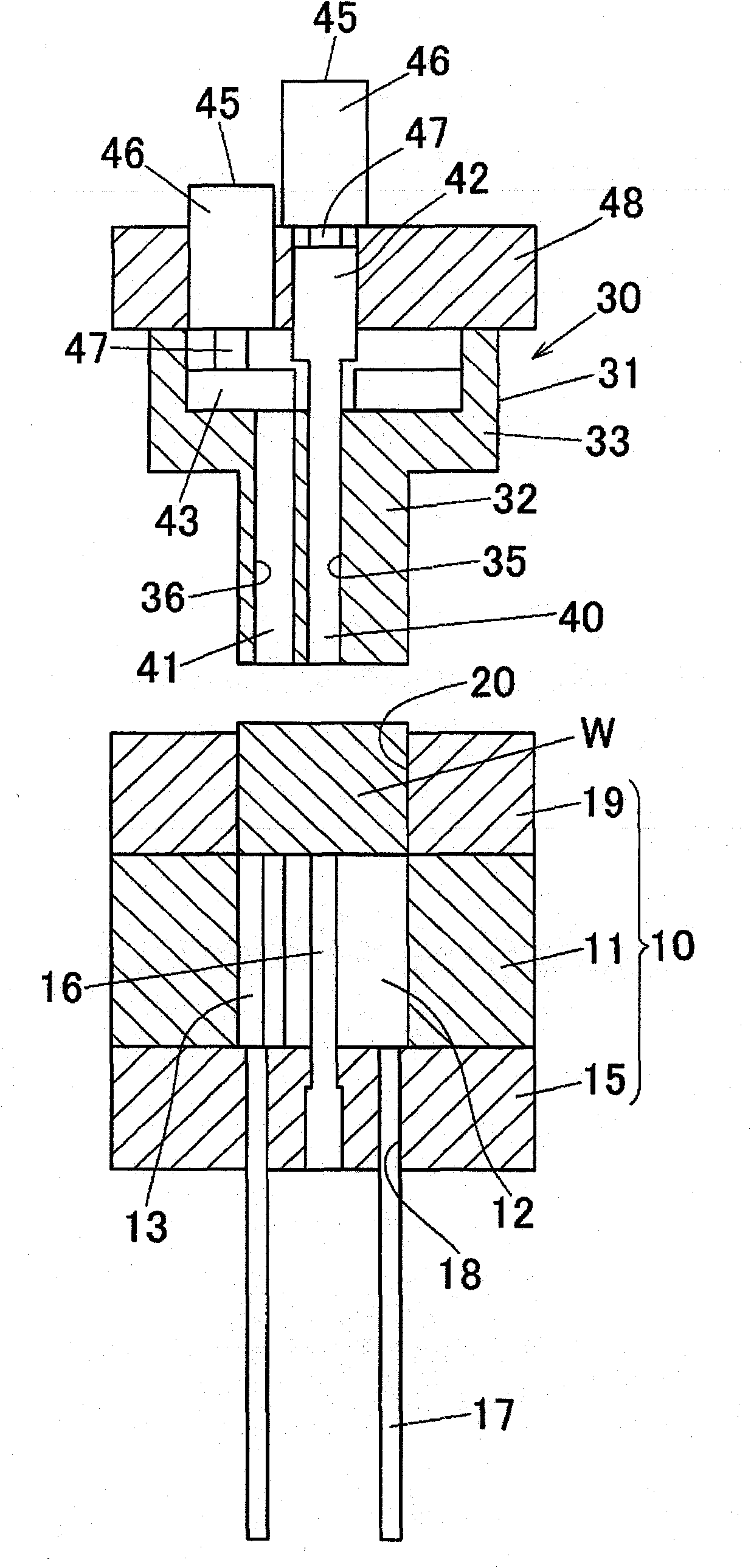

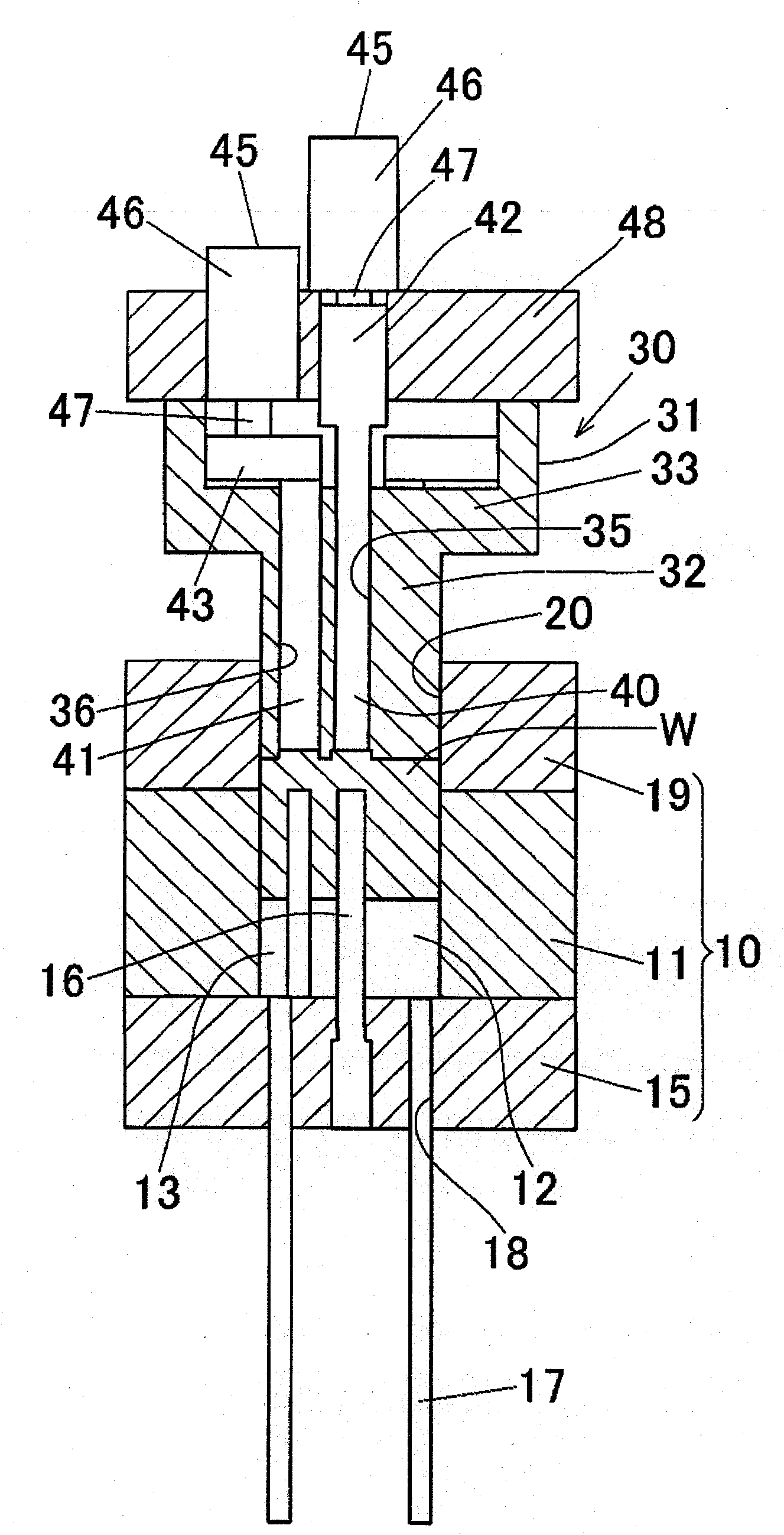

[0219] use figure 1 Forged with the forging die (10), (30) shown in Fig. 2 image 3 Indicated rotor blank (1). The above-mentioned rotor blank (1) is used to manufacture Figure 4 The material of the aluminum alloy rotor (R) shown.

[0220] In the above rotor (R), the outer diameter is 52mm, the height is 50mm, the diameter of the center hole (3) is 10mm, the number of blade grooves (4) is 5, the groove width is 3mm, the groove depth is 15mm, the offset dimension (U) is 10mm. In addition, A390 was used as the material alloy.

[0221] In addition, as shown in the following Table 1, in the above-mentioned forging die, the gap (D5) between the center pin (16) of the lower die (10) and the circular hole (35) of the upper die (30) is set to 0.1mm, The gap ( D6 ) between the blade portion ( 13 ) of the lower mold ( 10 ) and the flat hole ( 36 ) of the upper mold ( 30 ) was also set to 0.1 mm in the same manner as above.

[0222] In addition, the distance (breaking length D3) b...

Embodiment 2

[0232] As shown in Table 1, except that the breaking lengths (D3) and (D4) of the remaining parts (5) and (6) were set to "0", the rotor (R) was produced in the same manner as in Example 1 above. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com