Knife cutting type paper lamination quick forming machine

A paper lamination and forming machine technology, applied in metal processing, etc., can solve the problems of complex structure, high cost, strict requirements on environment and detection circuit, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

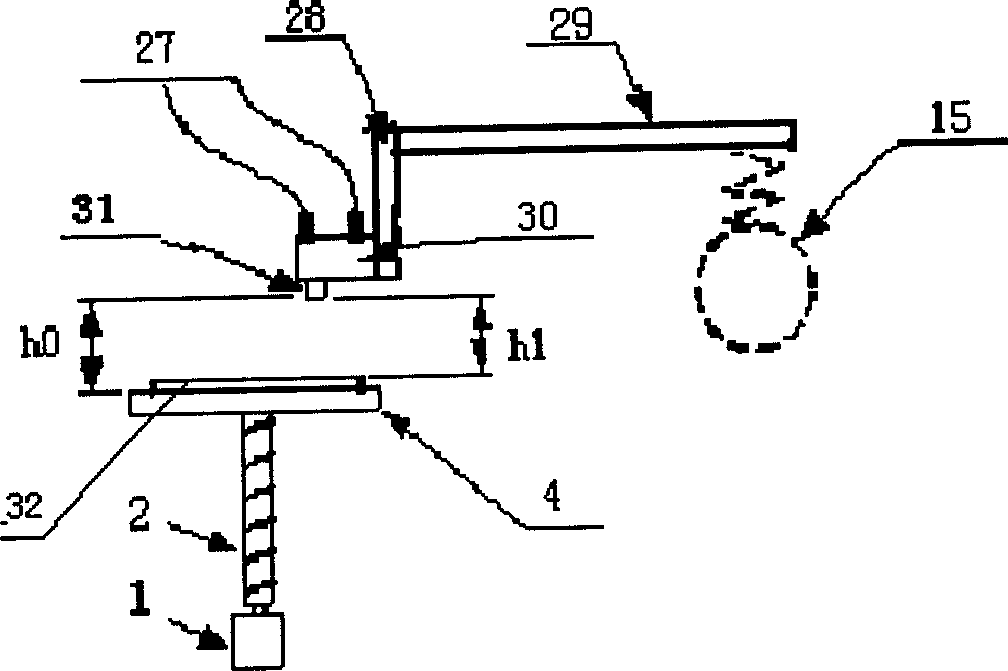

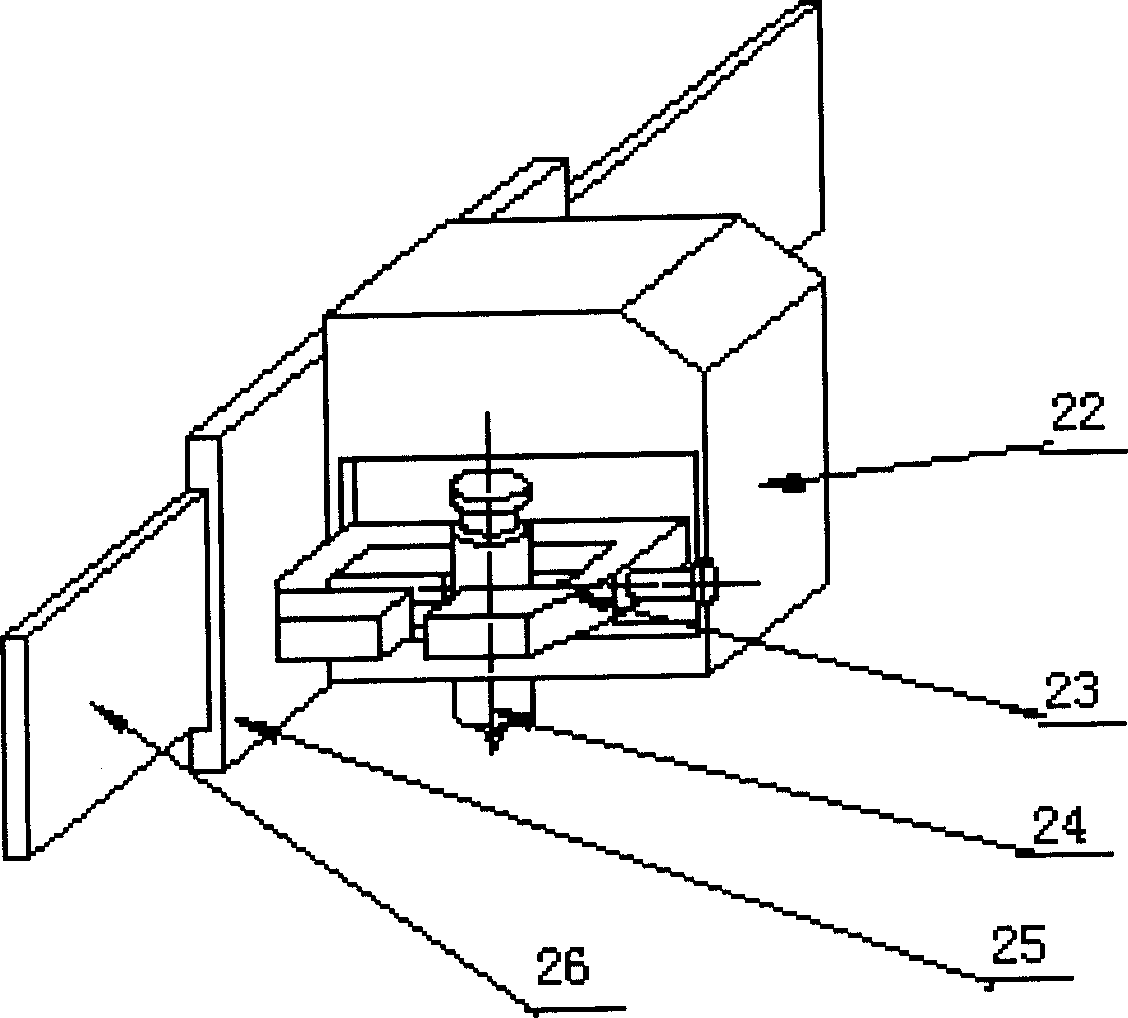

[0021] refer to figure 1 , The knife-cut type paper lamination rapid prototyping machine of the present invention is composed of a worktable motion system, a paper conveying system and a mechanical knife cutting system.

[0022] The workbench motion system is composed of a work platform 4, a transmission guide rail 2, a transmission screw 3 and a motor 1, the guide rail 2 is arranged under the work platform 4 and cooperates with the transmission screw 3, and the transmission screw 3 is connected to the motor 1; The workbench 4 provides a production platform, which is driven by a leading screw 3 connected to a stepping motor 1 and a transmission guide rail 2 .

[0023] The paper delivery system of the present invention is composed of a drive roller set 16, a paper guide roller set 18, a paper tape raw material roll 19, a paper roll support 20 and a hot pressing roller 15, and the above devices are all arranged on the paper feeding side of the working platform 4; Wherein the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com