Opto-electronic device integration

A device and laser technology used in the field of integration of high-yield density integrated optoelectronic devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

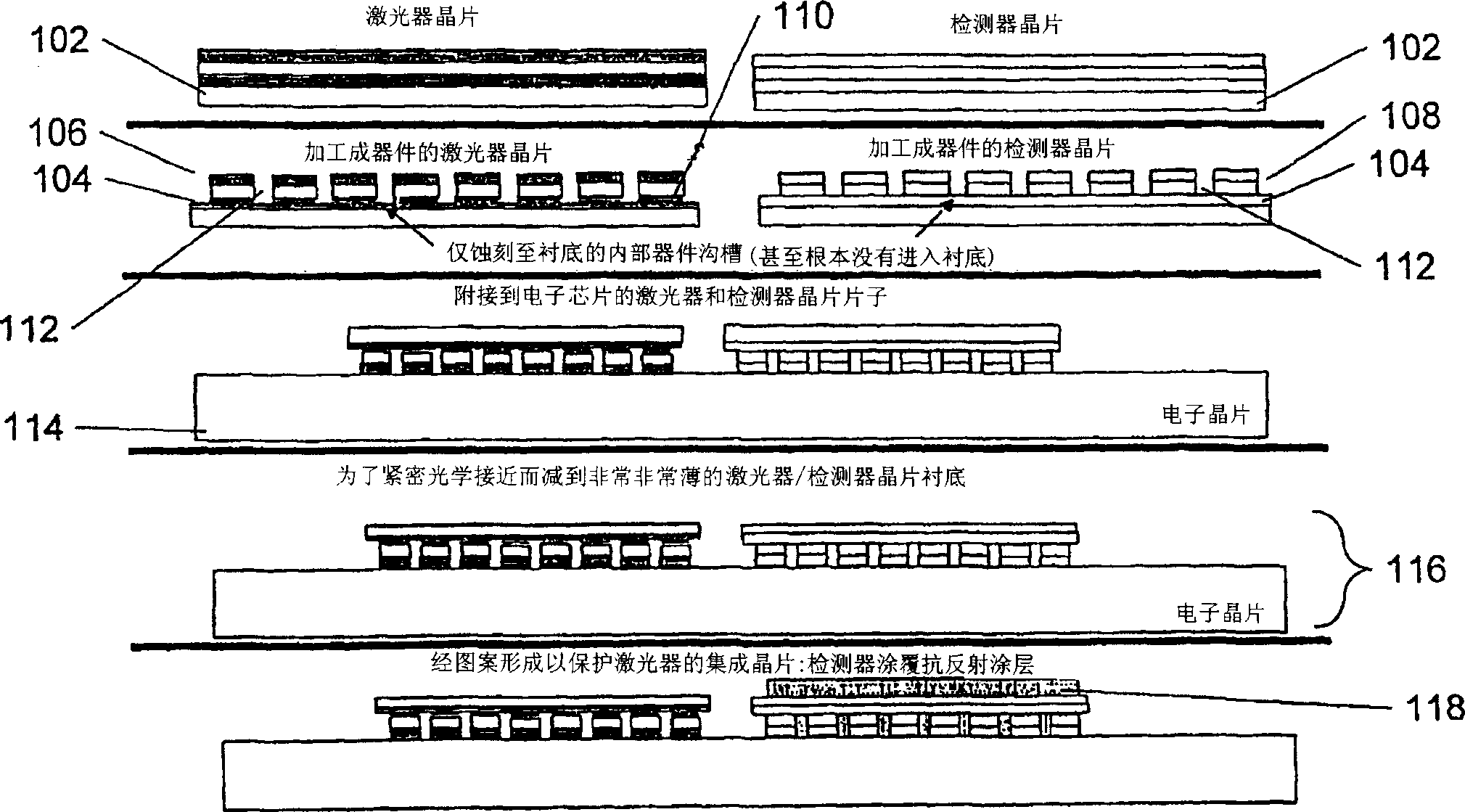

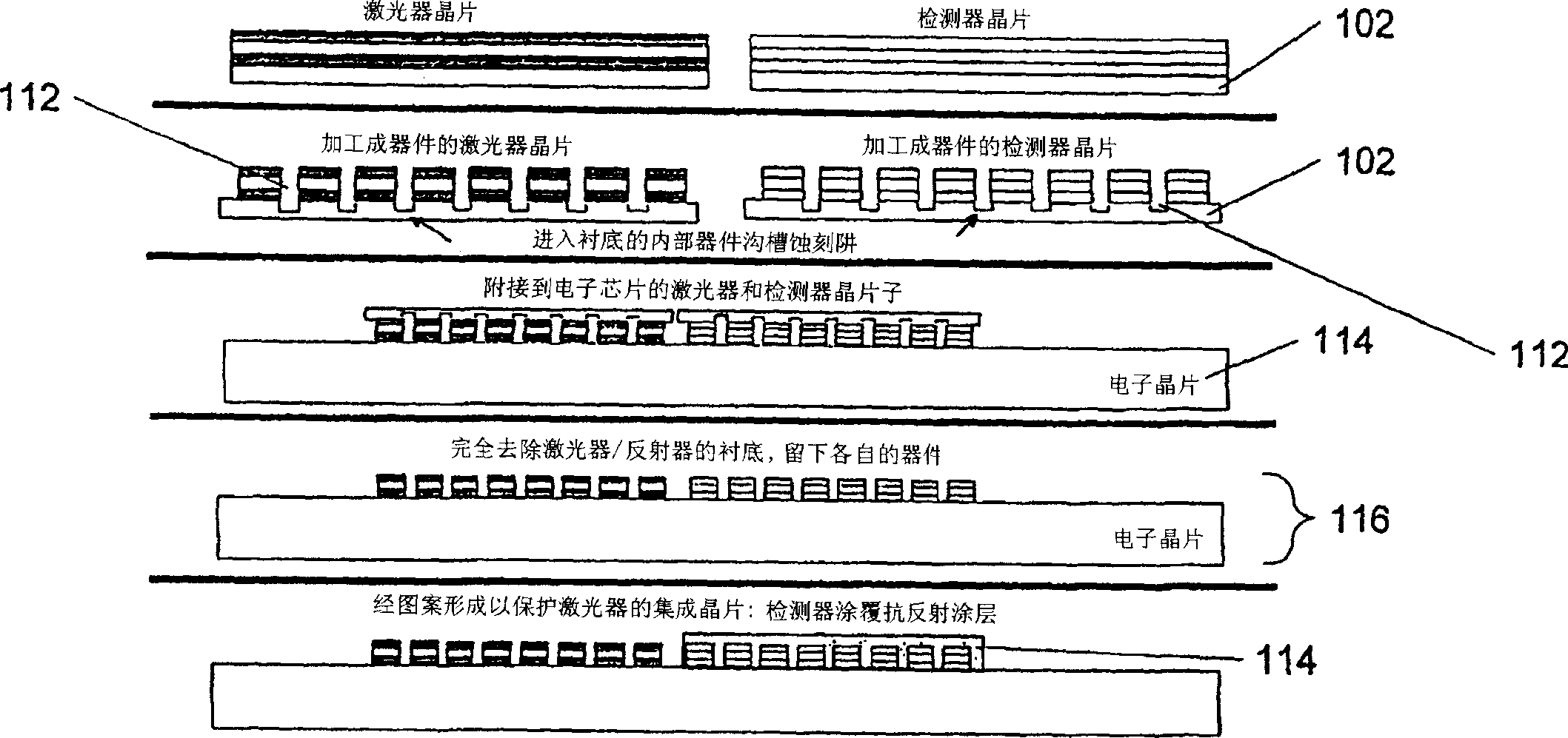

[0064] Figure 5 An exemplary method according to the teachings of the present invention is shown at a simplified high-level overview. This approach overcomes the shortcomings of previous approaches, while allowing optical access, removing absorbing regions, providing higher structural integrity, and having better heat dissipation properties.

[0065] exist Figure 5 A laser wafer 502 (consisting of lasers integrated on substrate 102) and a detector wafer 504 (consisting of lasers integrated on detector on the bottom 102). Alternatively, a hybrid wafer made of lasers and detectors integrated on a common substrate is fabricated or obtained eg in some alternate pattern or other combination.

[0066] The trenches 506 are etched to allow the wafer to be processed into individual devices (by etching the trenches into the substrate), or, in some cases, for example, as in a document entitled "Redundant Device Array" and contemporaneously herein As shown in the commonly assigned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com