Solid phase benzopyran composition, process for preparing same and organoleptic uses thereof

A technology of benzopyran and composition, which is applied in the field of new solid-phase aromatic products, to achieve the effect of easy operation and reduced emission in the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

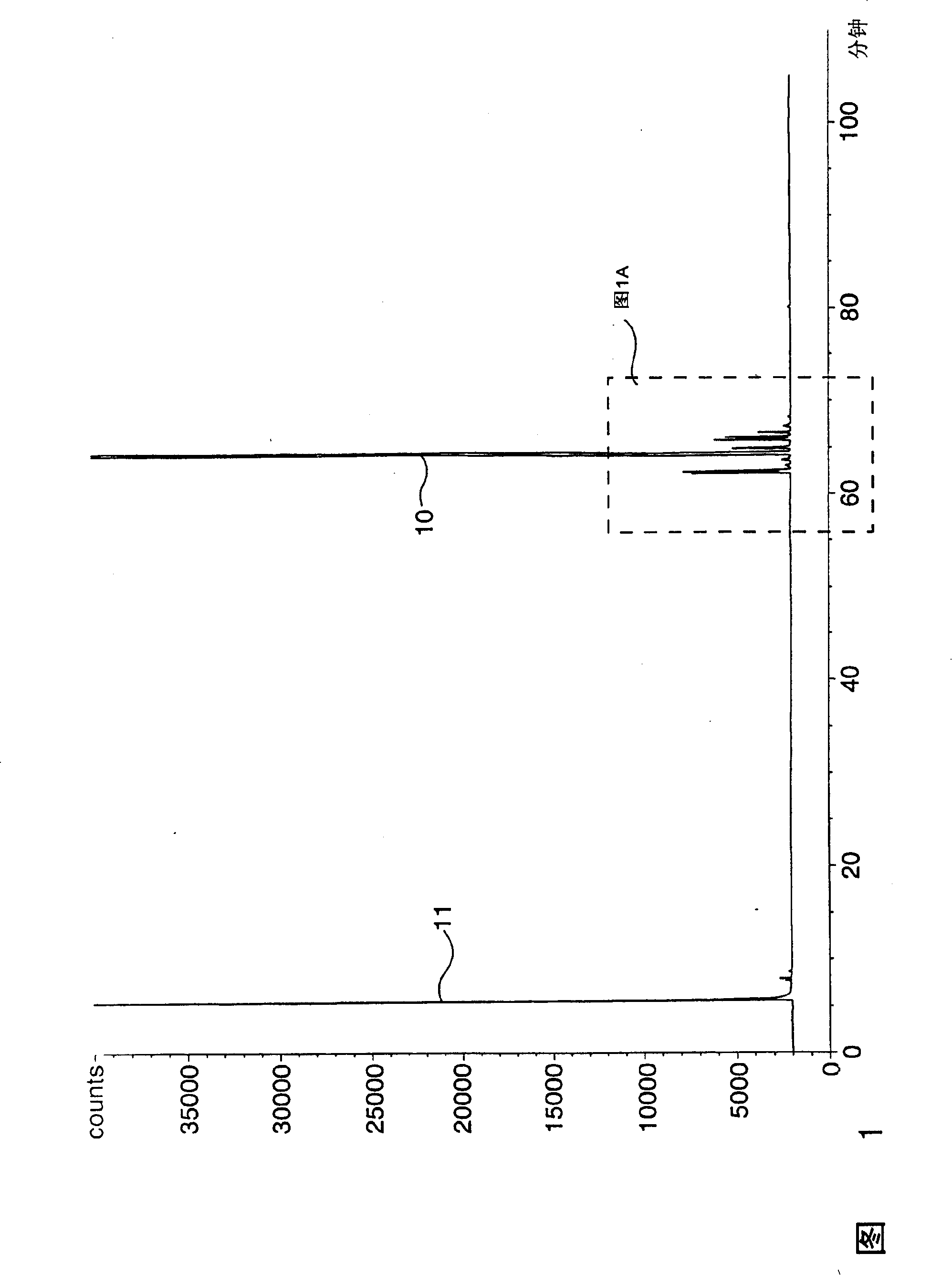

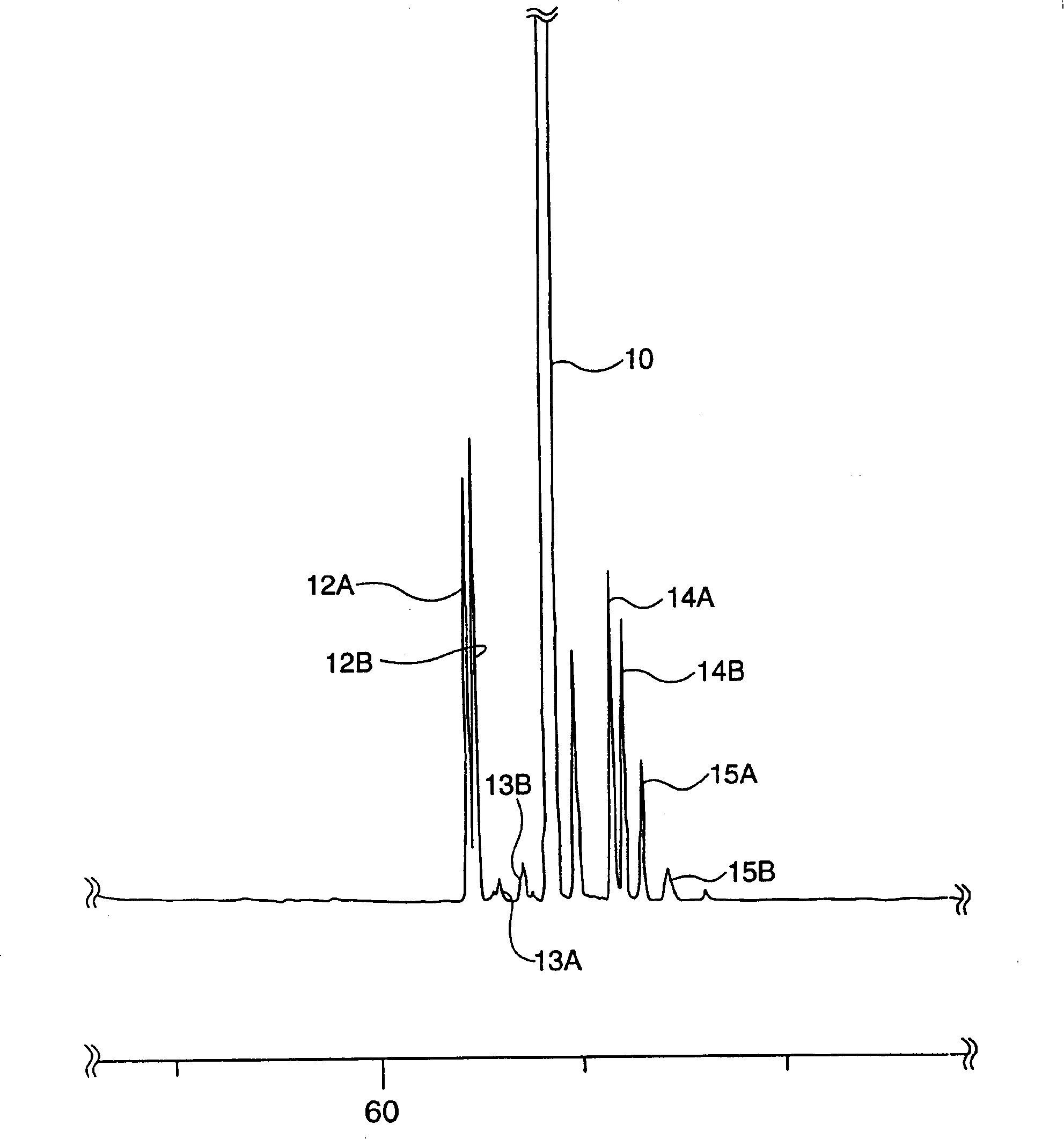

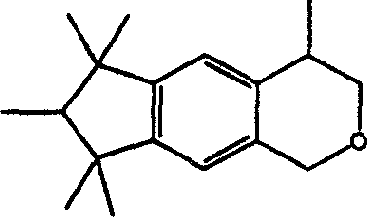

[0076] Preparation of solid-phase benzopyran composition

[0077] 750 g of liquid phase benzopyran mixture was prepared according to Example 15 of U.S. Pat. No. 3,360,530 (the specifications of which are incorporated by reference), said mixture containing 78% by weight of 1,3,4,6,7, 8-hexahydro-4,6,6,7,8,8-hexamethylcyclopenta(G)-2-chromene and 500 g of hexane, the two components of the mixture were mixed Then it was stirred and cooled to -30°C. Stirring was continued for 1 hour, at which point the solid phase particles just started to settle. The mixture was stirred for an additional 3 hours while slowly raising the temperature of the benzopyran-solvent mixture to 0° C., and the white solid was filtered at 0° C. to finally obtain 240 g of a mixture containing the following weight percent substances:

[0078] (a) 88.6% by weight 1,3,4,6,7,8-hexahydro-4,6,6,7,8,8-hexamethylcyclopentadieno(G)-2-benzopyridine mutter;

[0079] (b) 2.75% by weight 1,3,4,6,7,8-hexahydro-6-ethyl-...

Embodiment II

[0085] Preparation of solid-phase benzopyran composition

[0086]200 g of liquid phase benzopyran mixture was prepared according to Example 15 of U.S. Pat. 7,8,8-hexamethylcyclopentadieno(G)-2-chromene and 100 g of 10% aqueous ethanol, the two components of the mixture were mixed and cooled to +5°C with stirring. Stirring was continued for 2 hours, at which time solid phase particles began to settle. The mixture was then stirred at 5°C

[0087] After stirring for 3 hours, 42 g of white crystalline material were obtained by filtration at 5°C. The resulting composition is a solid phase

[0088] Benzopyran mixtures containing 91% by weight of 1,3,4,6,7,8-hexahydro-4,6,6,7,8,8-hexamethyl rings having a melting point of 31°C Pentadieno(G)-2-benzopyran.

Embodiment III

[0090] Musk fragrance composition

[0091] components Embodiment III (A)- parts by weight Example III (B) - parts by weight sunflower musk 200 200 Muscone 200 200 β-ionone 50 50 Vebisyl Acetate 50 50 Sandalwood Oil, E.I. 100 100 β-Damascone 80 80 Solid phase benzopyran composition in embodiment 1 10 0 Solid Phase Benzopyran Composition in Example II 0 10

[0092] The solid-phase benzopyran compositions of Examples I and II respectively endow this musk formulation with natural, aromatic, musk, rose scent and this scent has animal-type top notes and is very strong and direct, each composition and formulation The materials mix well without the use of any solvents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com