Fuel distribution device for fuel feed ducts, and fuel supply device with the fuel distribution device

A fuel supply and fuel distribution technology, which is applied in the field of fuel distribution devices in fuel supply pipelines, can solve problems such as coal concentration cannot be adjusted, gas temperature drops, etc., and achieve the effect of easy adjustment and increased concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

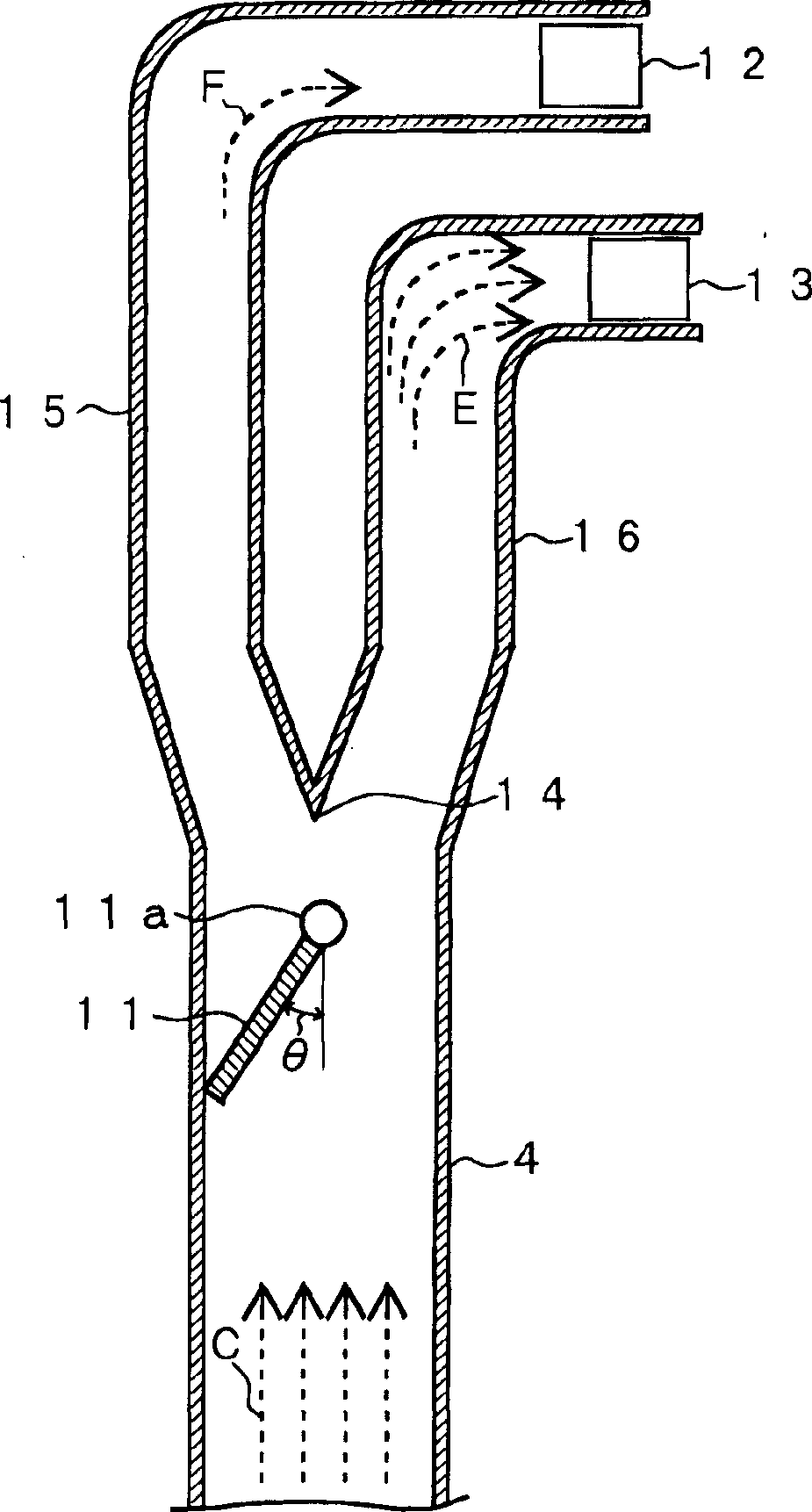

[0091] figure 1 Shown is a cross-sectional view of the main parts of the fuel supply pipe of this embodiment, figure 2 Shown is the configuration in figure 1 A detailed structural drawing around the damper on the fuel supply line.

[0092] figure 1 The fuel supply pipe is branched from the main pipe 4 extending in the vertical direction, the damper 11 arranged at the upstream part near the pipe branch point 14 in the main pipe 4, and the branch connected to the upper burner 12 and the lower burner 13 respectively. The branch pipes 15, 16 etc. constitute.

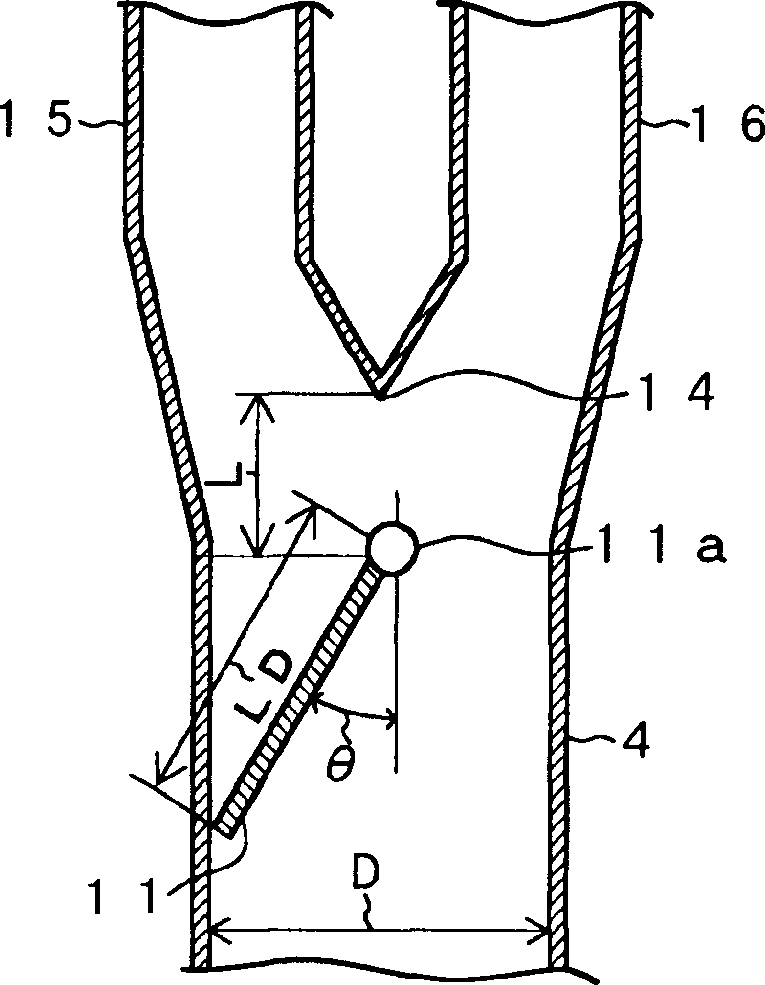

[0093] Such as figure 2 As shown, on the damper 11 , the damper hinge shaft 11 a is provided near the center of the main duct 4 in a direction crossing the main duct 4 .

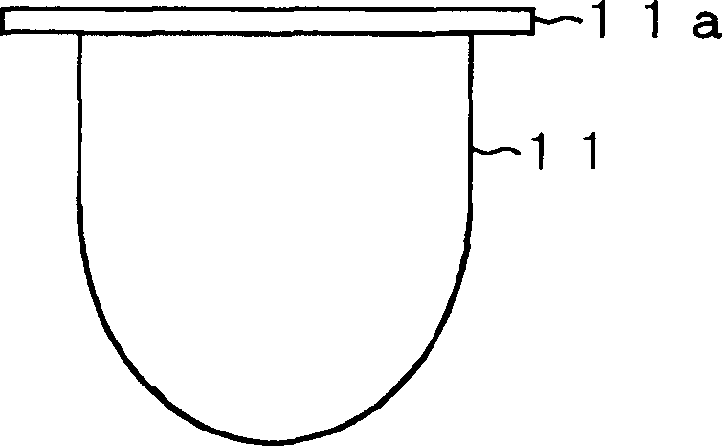

[0094] Such as figure 2 As shown, the present embodiment is an example in which the damper hinge shaft 11 a is provided at the upper end portion of the damper 11 . image 3 Shown is a top view of the damper 11 , the damper 11 is roughly semici...

no. 2 Embodiment

[0097] Figure 4 Shown is a modified example of the first embodiment—a cross-sectional view of the main parts of the fuel supply pipeline of this embodiment, Figure 5 Shown is Figure 4 A top view of the damper. The damper 11 has the same circular shape as the cross-sectional shape of the main duct 4 .

[0098] Also in this case, the damper hinge shaft 11a can be rotated to keep the damper 11 at an appropriate inclination angle θ.

[0099] Image 6 Shown is the coal concentration ratio supplied to the lower burner 13 in the first embodiment and the second embodiment and the length (L1) from the upper end of the damper 11 to the hinge shaft 11a relative to the maximum width (LD) of the damper. The relationship between the value of the ratio (L1 / LD). Also, the coal concentration ratio supplied to the lower burner 13 is the ratio of the coal concentration in the mixed fluid in the main pipe 4 to the coal concentration supplied to the lower burner side branch pipe 16 .

[0...

no. 3 Embodiment

[0112] Figure 9 Shown is an example of a fuel supply pipeline with a rectangular cross section. Its structure is that branch pipelines 15, 16 that are separated from the main pipeline 4 and respectively connected to the upper burner 12 and the lower burner 13 extend upwards side by side. The vicinity of the lower floor burner 12,13 is separated respectively. The damper 11 is arranged in the main duct 4 in front of a branch point which divides into the upper burner 12 and the lower burner 13 .

[0113] Such as Figure 9 As shown, the structure of the damper 11 is to keep the hinge shaft 11a on the upstream side of the vertical line passing through the branch point 14, and the hinge shaft 11a is arranged on the upper end of the damper 11, as Figure 9 As shown, since the damper 11 is inclined to the side of the branch pipe 15 communicating with the upper burner 12, compared with the coal particle concentration in the mixed fluid F passing through the branch pipe 15 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com