Low temperature heat supply reactor having high safety

An inherently safe and heating reactor technology, applied in the field of nuclear reactors, can solve the problems of economic and safety that are not widely accepted by people, and achieve the effects of reduced cost, high safety and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

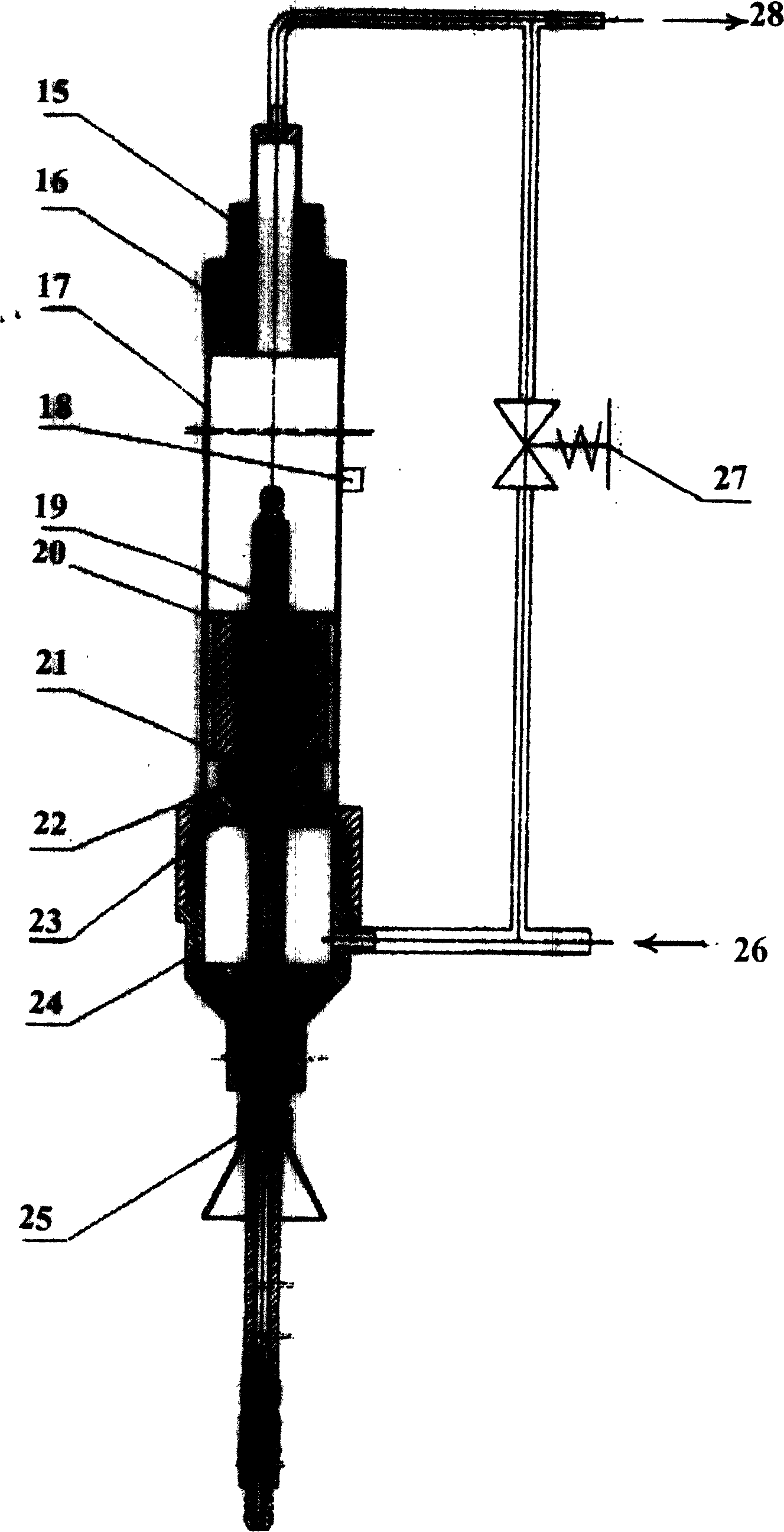

[0012] The present invention takes a heating stack with a thermal power of 200MW as an example, its structure is as follows figure 1 shown.

[0013] This reactor should be called a pool-shell reactor, which has the characteristics of a pool-type reactor and a sealed core container. The reactor core 1 is placed in the center of the lower part of the core vessel 2, and is fixed by a hanging basket 3, which is hung between the reactor coolant outlet pipe 6 and the reactor coolant inlet pipe 7 of the core vessel 2, and the coolant is passed in and out. The nozzle is isolated, and the complex sealing structure between the coolant outlet 6 pipe and the hanging basket 3 is eliminated, and the core vessel 2 is supported on the core concrete shielding layer by the upper part. The control rod driving mechanism 5 is arranged on the spherical stack container top cover 4 of the core container 2 and rigidly connected with the control rod absorber.

[0014] During normal operation, the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com