Dehydrogenation tail gas absorption method for preparing styrene from ethylbenzene

A technology of tail gas absorption and tail gas absorption tower, which is applied in the direction of chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of no dehydrogenation tail gas, no use of energy, low recovery rate of aromatics, etc., and achieve temperature reduction , The cooling water volume is reduced, which is beneficial to the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

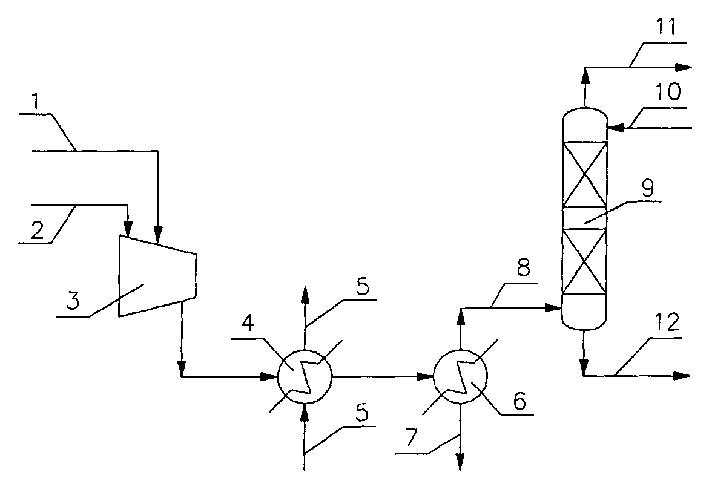

[0022] press figure 1 The process dehydrogenation tail gas has a mass flow of 521.5 kg / h of hydrogen, 44.5 kg / h of methane, 290.4 kg / h of carbon dioxide, 139.2 kg / h of benzene, 58.3 kg / h of toluene, 1.8 kg / h of non-aromatic hydrocarbons, and 172.5 kg / h of ethylbenzene. Hours, 103.1 kg / h of styrene and water with a mass flow rate of 160.2 kg / h enter the tail gas compressor. The outlet temperature of the tail gas compressor is 128.6℃ and the pressure is 205KPa. Then the material enters a dehydrogenation liquid as the cold medium. The outlet temperature of the heat exchanger is 75°C and the pressure is 200KPa. Then the material enters a tail gas cooler. After cooling by the cooling water, the outlet temperature is 38°C, and enters the lower part of the tail gas absorption tower. , Use polyethylbenzene residue oil containing mixtures of triethylbenzene and tetraethylbenzene as the absorbent to enter from the upper part of the tail gas absorption tower, the absorbent feed temperature ...

Embodiment 2

[0024]According to the conditions and steps of Example 1, except that the absorbent feed temperature is changed to 15°C, the theoretical number of plates in the tail gas absorption tower is 10, and the top pressure of the tail gas absorption tower is 190KPa. As a result, the heat recovery of the heat exchanger is 790 kilowatts, the recovery rate of aromatics in the dehydrogenation tail gas is 96.7%.

Embodiment 3

[0026] According to the conditions and steps of Example 1, except that the absorbent feed temperature is changed to 10°C, the pressure at the top of the tail gas absorption tower is 160KPa, the result is that the heat recovery of the heat exchanger is 673 kW, and the recovery rate of aromatics in the dehydrogenation tail gas is 98.1 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com