Dry process stack gas desulfur system using malti tower in parallel structure

A dry flue gas desulfurization and parallel technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as the inability to meet the fluidization requirements of large-scale flue gas desulfurization reactions, and achieve low desulfurization technical requirements. , the effect of reducing height, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

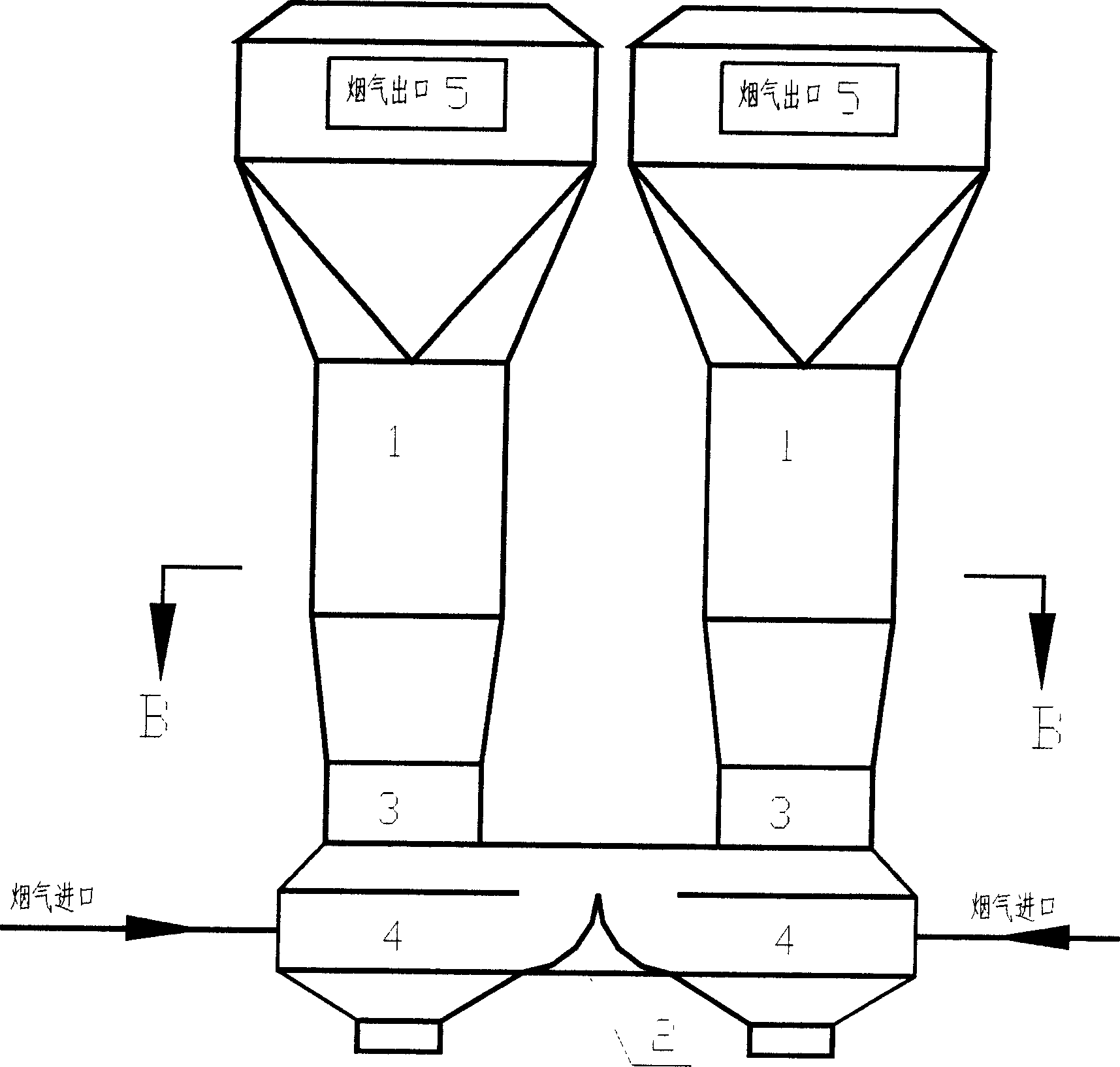

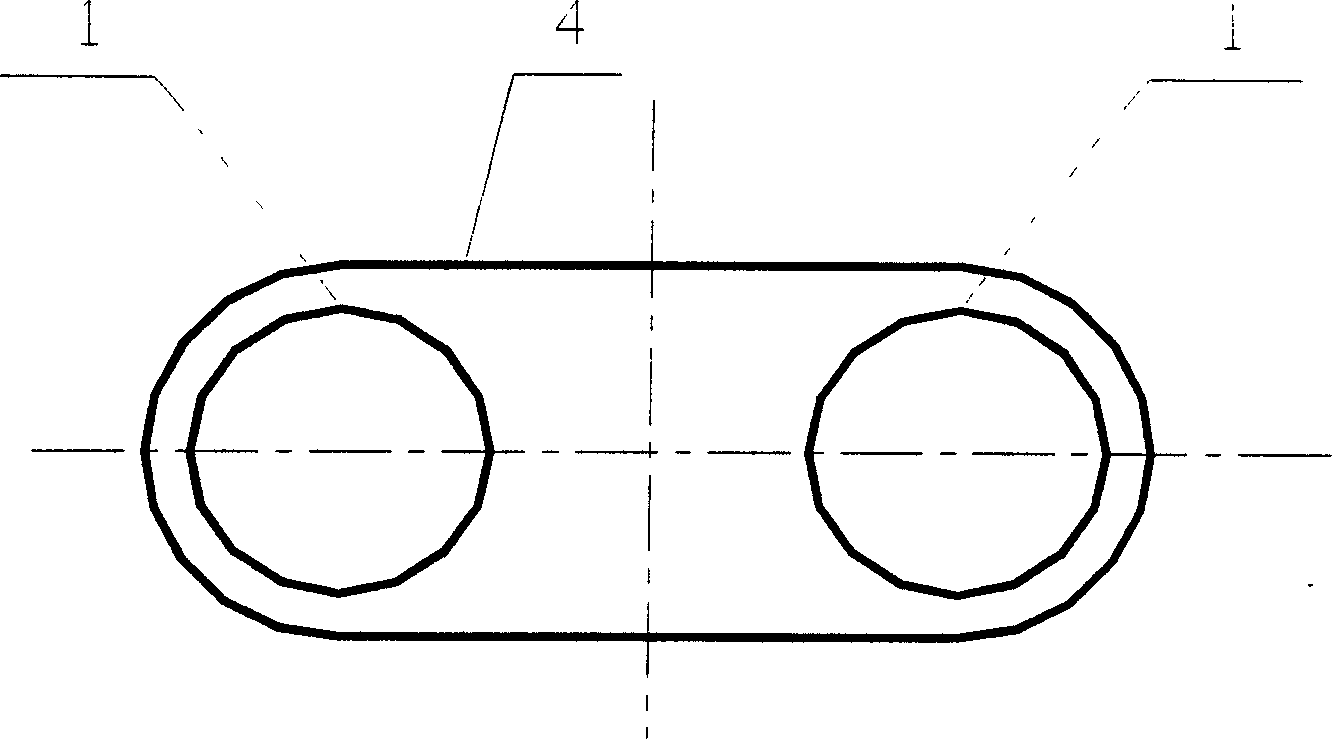

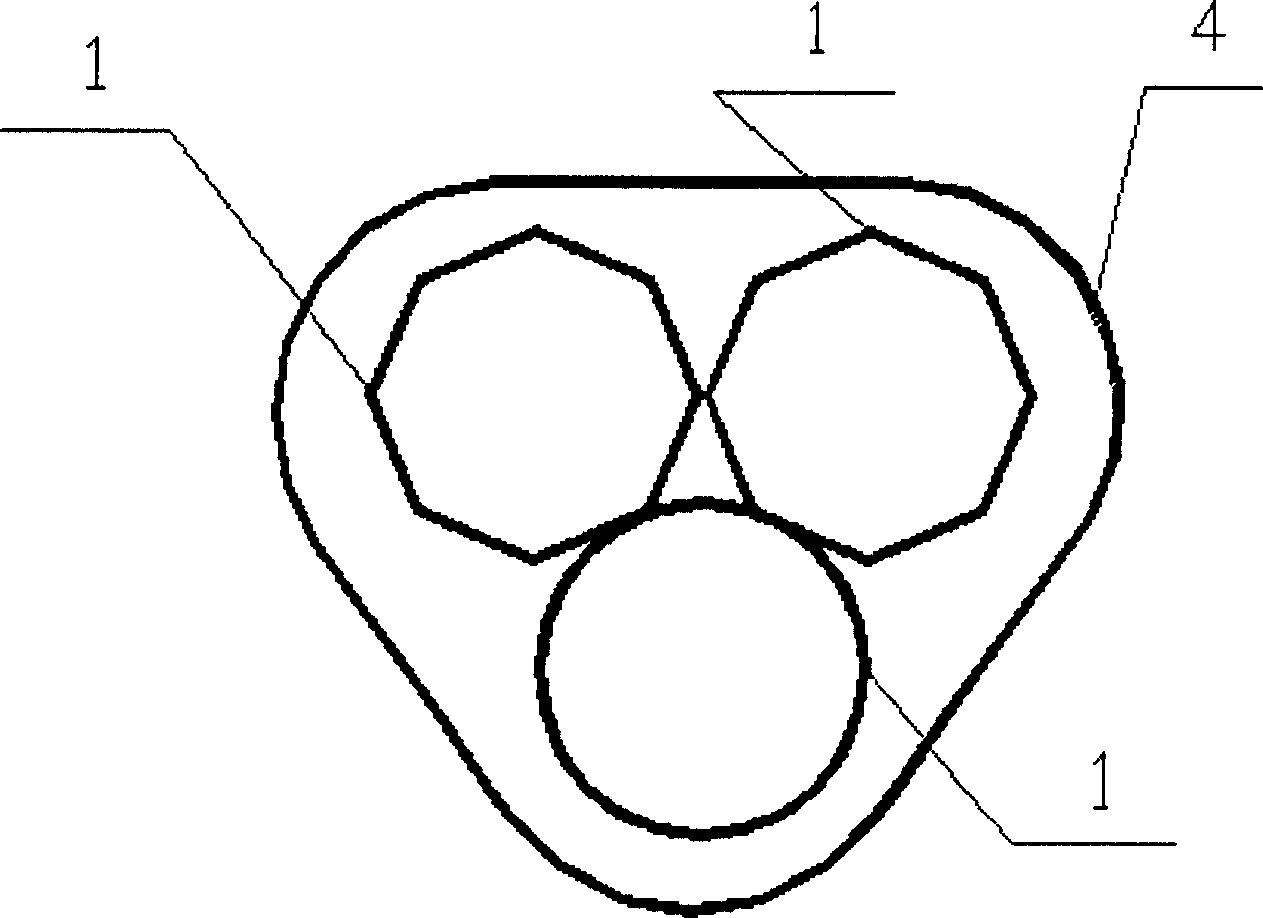

[0023] The present invention provides an example of a thermal power generation unit with a single installed capacity of 600MW, and adopts a dry flue gas desulfurization reaction system with the characteristic of parallel connection of two sub-desulfurization reaction towers.

[0024] First, the flue gas discharged from the combustion equipment passes through a flue gas pre-dust removal device 6 (such as electrostatic precipitator, bag filter, inertial separation dust collector or their combination), to remove about 90% of the fly ash in the flue gas, after The flue gas after pre-dust removal is sent into the flue gas mixing chamber 4, and the flue gas is evenly distributed to the flue gas injection acceleration of each sub-desulfurization reaction tower 1 through the flue gas deflector 2 arranged in the flue gas mixing chamber 4 In the device 3 (such as a Venturi nozzle), the outlet velocity range of the flue gas jet is maintained at 10-55m / s, and is accelerated to enter the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com