Electric brush motor for electric power turning device

An electric power steering, electric motor technology, applied in power steering mechanism, electric steering mechanism, electromechanical device, etc., can solve problems such as poor steering feel, reduction of motor boost torque, and increased noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiment 1

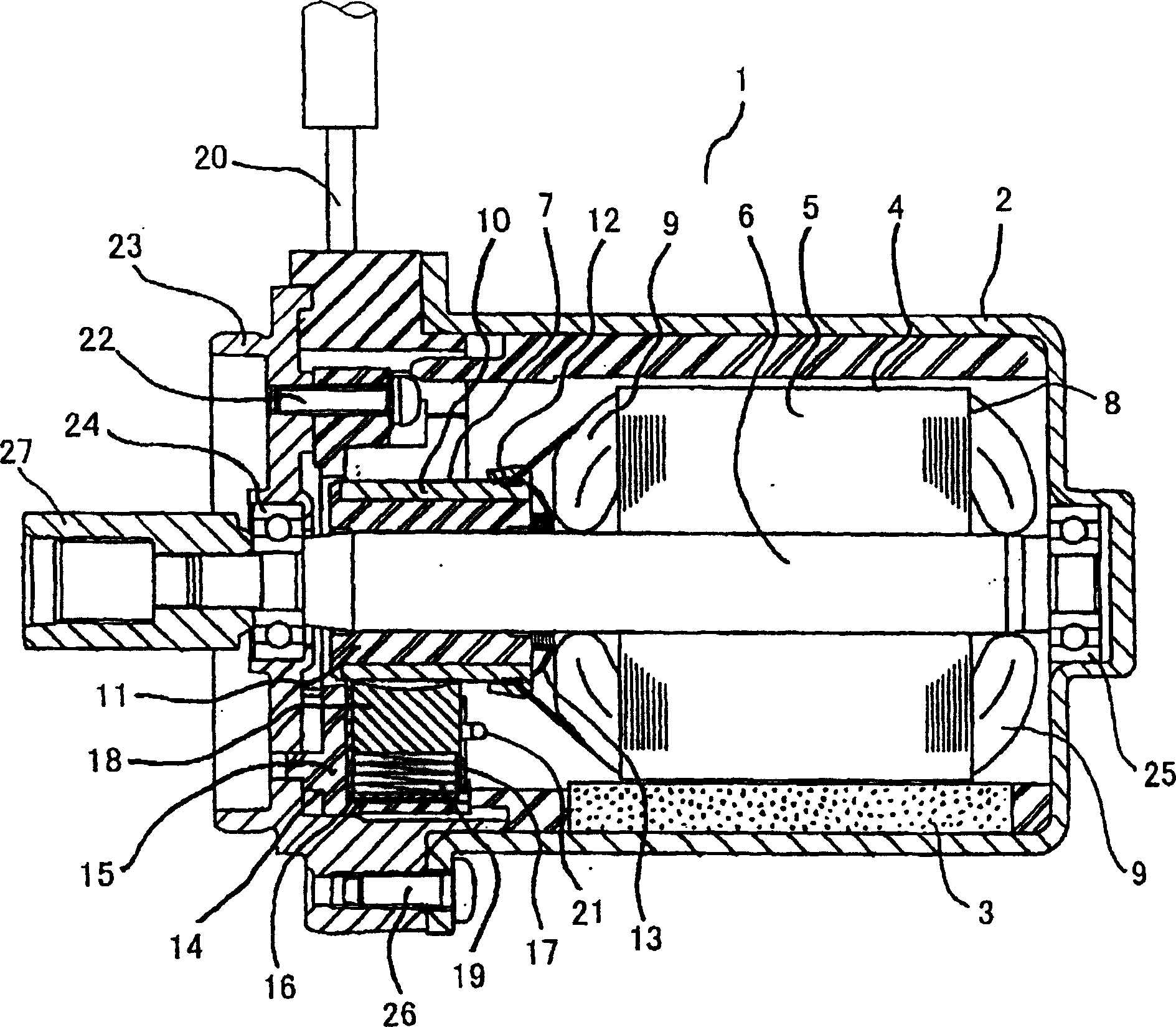

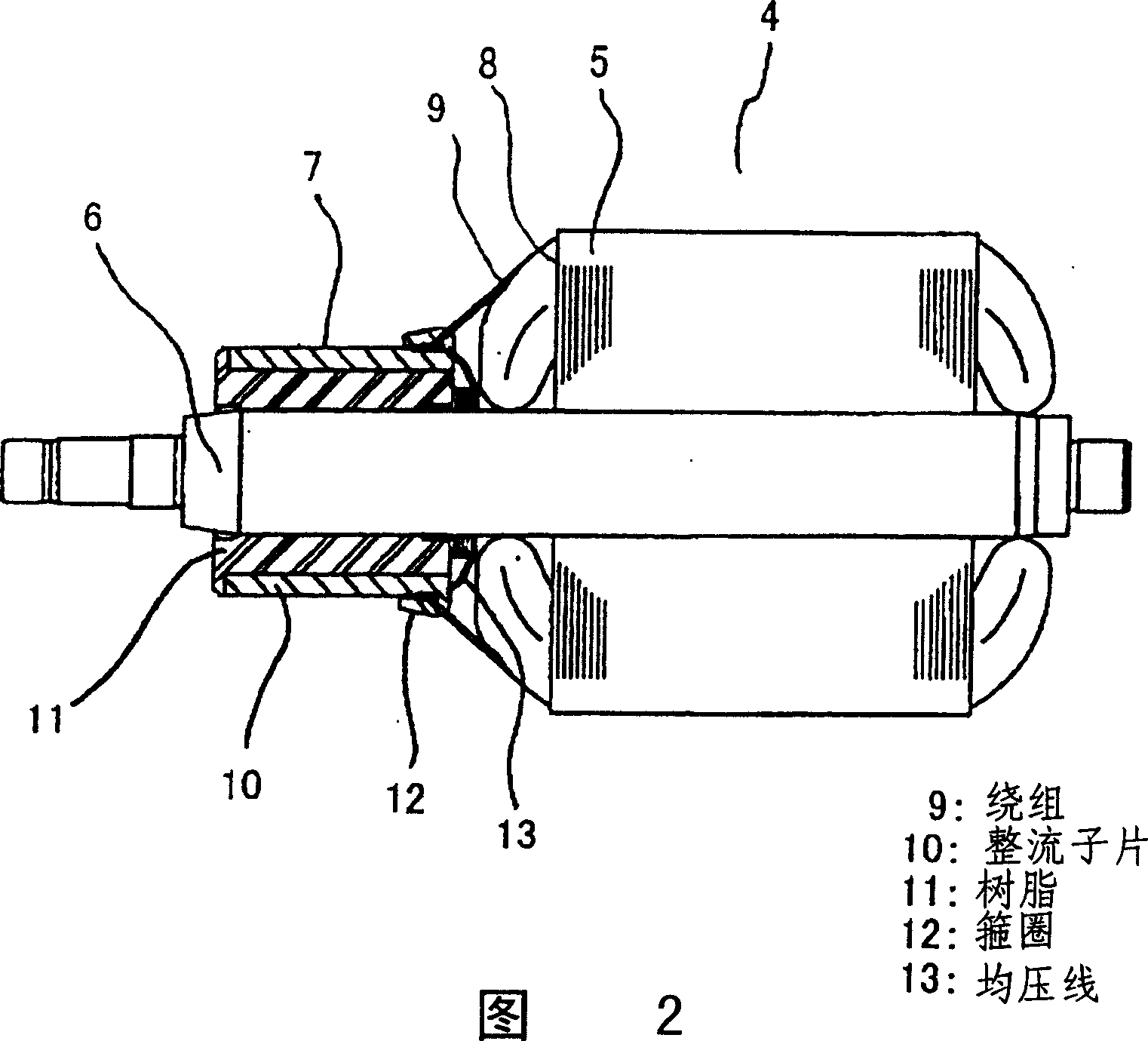

[0051] Fig. 1 is a sectional view showing a brush motor for an electric power steering system according to Embodiment 1 of the present invention, and Fig. 2 is a sectional view showing a main part of an armature thereof. The same symbols are assigned to the same or identical parts in the following drawings for description. In the drawing, a brush motor 1 for an electric power steering device is fixed with a magnet 3 constituting a four-pole field section on the inner wall surface of a yoke 2, and on the inner diameter side of the magnet 3 is connected to the iron of the armature 4 via a predetermined air gap. Core 5 is opposite. The armature 4 is equipped with an iron core 5 and a commutator 7 fixed on the rotating shaft 6. The iron core 5 composed of laminated electrical steel sheets has 22 slots 8, and the wire diameter is about 0.7 mm in the slot 8 in a stacked winding manner. Windings composed of enameled wire, etc. 9

[0052] The commutator 7 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com