Plant-type hollow fibre membrane assembly

A technology of external pressure hollow fiber and membrane modules, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of unsuitable submerged membrane bioreactors and unsuitable submerged membrane modules, etc., and achieve easy transportation Compatible with construction and installation, reducing energy consumption and high filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

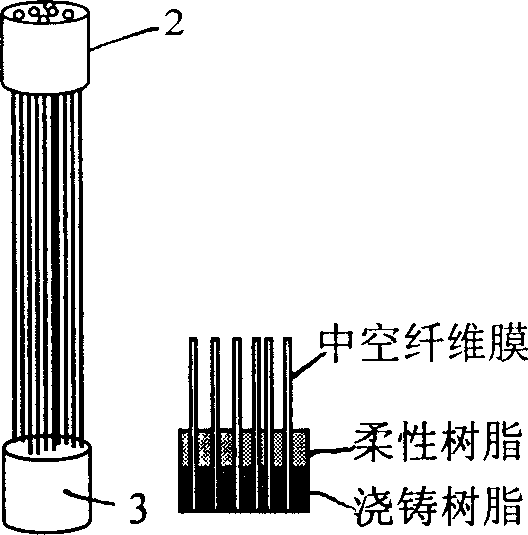

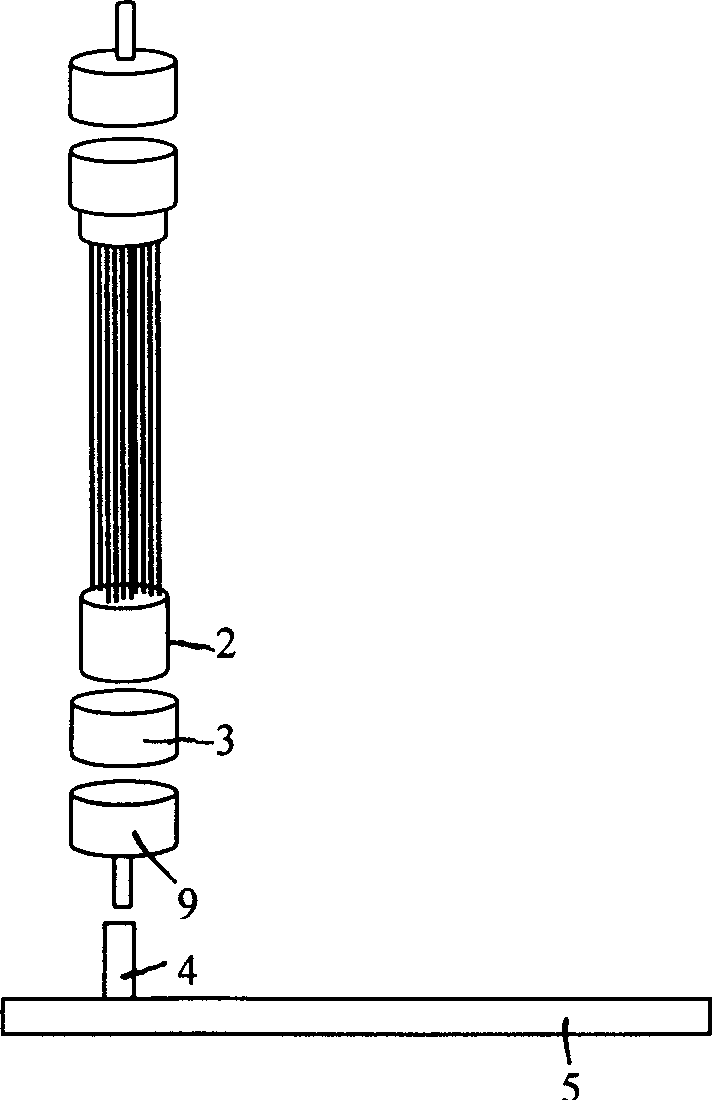

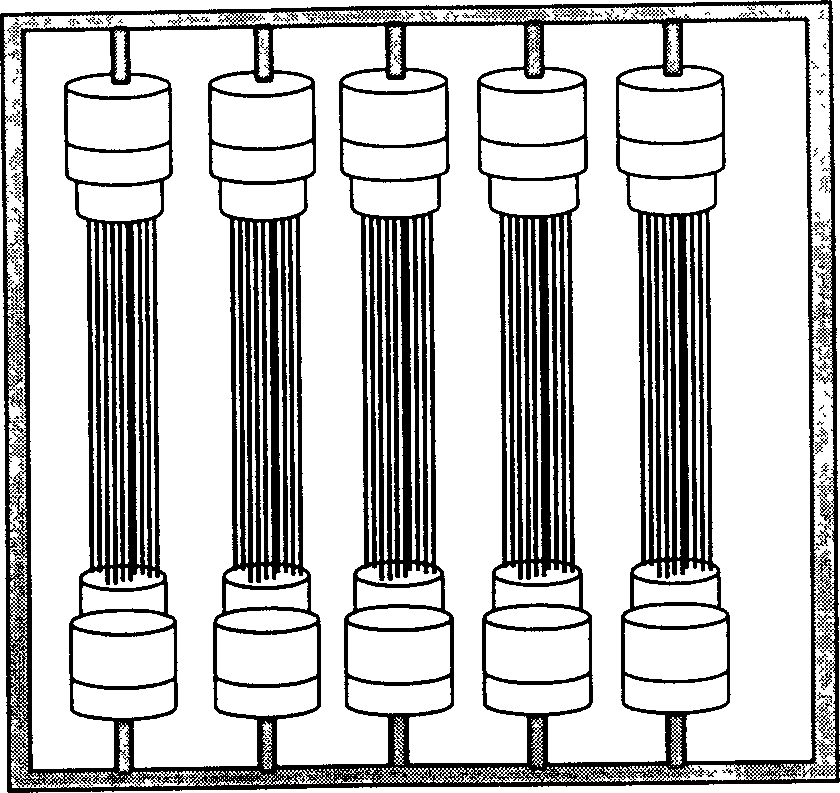

[0016] Such as figure 1 , figure 2 As shown, the single-branched membrane module of the present invention has a structure without a shell casing, which includes an upper end 2 , a lower end 3 , and a hollow fiber membrane 1 for external pressure. Such a membrane module is suitable for use submerged in water. The hollow fiber membranes at the upper and lower casting ends are perforated to lead out the filtrate. Cast end housings can be round or square as shown. The hollow fiber membrane material can be known hollow fiber membranes such as polyvinylidene fluoride, polyethylene, polypropylene, polyethersulfone and the like. Using known casting resins such as epoxy resin and polyurethane for end-cap casting, and then using flexible resins such as silicone rubber and polyurethane for secondary casting of the hollow fiber membrane root can effectively solve the problem of membrane fiber root fracture and meet the use requirements. And make the end face of the flexible resin cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com