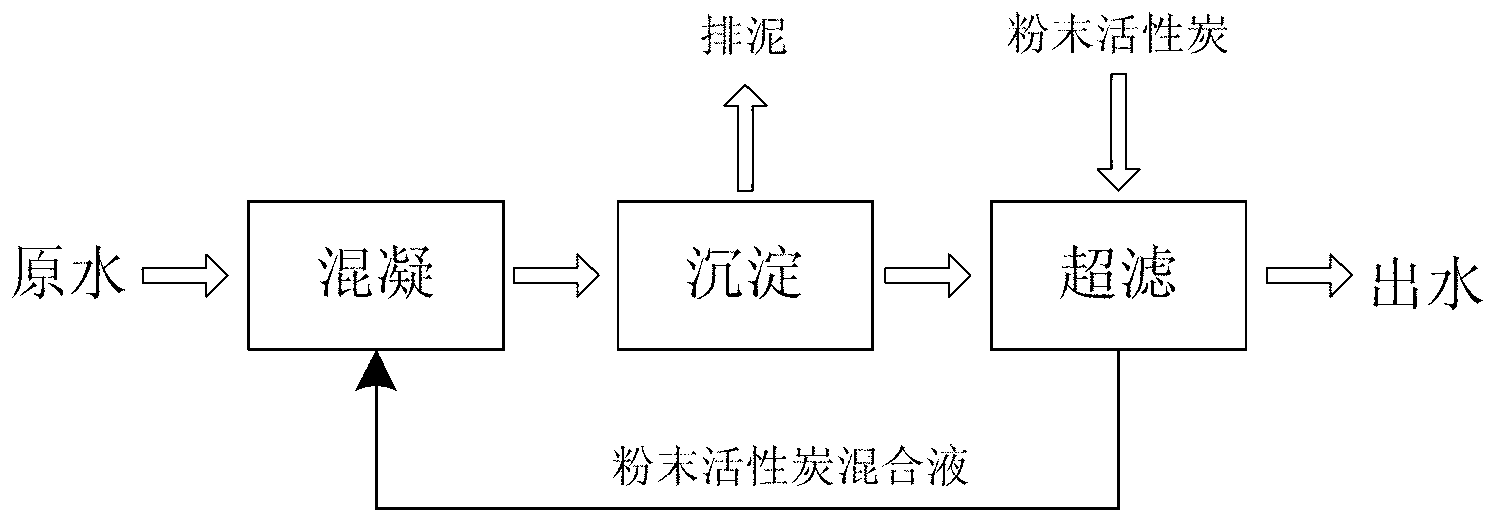

Powdered activated carbon reflux/ultrafiltration combined technology for water treatment plant

A technology of powder activated carbon and combined process, which is applied in the field of water treatment to achieve stable water production, reduce pollution pressure, and improve removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] In this example, coagulation-sedimentation-powder activated carbon / ultrafiltration combined process is used to treat slightly polluted water, the raw water turbidity is 5.76NTU, UV 254 is 0.058, and DOC is 4.45mg / L. The coagulation stage adopts a clapboard mixing tank, the coagulant adopts polyaluminum chloride with a dosage of 20mg / L (based on commercial quality), and the sedimentation stage adopts an inclined tube sedimentation tank, and the ultrafiltration membrane area is 0.100m 2 , the membrane flux is 40L / (m2.h), the volume of the membrane pool is 0.4L, the system flow rate is 4L / h, the dosage of powdered activated carbon is 5mg / L, and the residence time of the mixed liquid in the membrane pool is 2h. When there is no powdered activated carbon backflow, the turbidity of the sinking water is 1.80NTU, UV 254 is 0.028, DOC is 2.73mg / L, and the concentrated liquid in the membrane tank needs to be emptied every 2 hours. At this time, the water production rate of the s...

Embodiment 2

[0016] In this example, coagulation-sedimentation-powder activated carbon / ultrafiltration combined process is used to treat slightly polluted water, the raw water turbidity is 7.55NTU, UV 254 is 0.068, DOC is 5.32mg / L. The coagulation stage adopts a clapboard mixing tank, the coagulant adopts polyaluminum chloride with a dosage of 25mg / L (based on commercial quality), and the sedimentation stage adopts an inclined tube sedimentation tank, and the ultrafiltration membrane area is 0.100m 2 , the membrane flux is 40L / (m 2 .h), the volume of the membrane pool is 0.4L, the system flow rate is 4L / h, the dosage of powdered activated carbon is 20mg / L, and the residence time of the mixed liquid in the membrane pool is 10h. When there is no powdered activated carbon backflow, the turbidity of the sinking water is 1.92NTU, UV 254 is 0.029, DOC is 3.07mg / L, and the concentrated liquid in the membrane tank needs to be emptied every 10 hours. At this time, the water production rate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com