Radiator

A heat sink and cavity technology, applied in the field of heat dissipation equipment, can solve problems such as increasing the volume of the heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is usually made of metal materials with better thermal conductivity, such as aluminum, aluminum alloy,

[0016] and other materials, and the interior of the radiator is provided with a cavity.

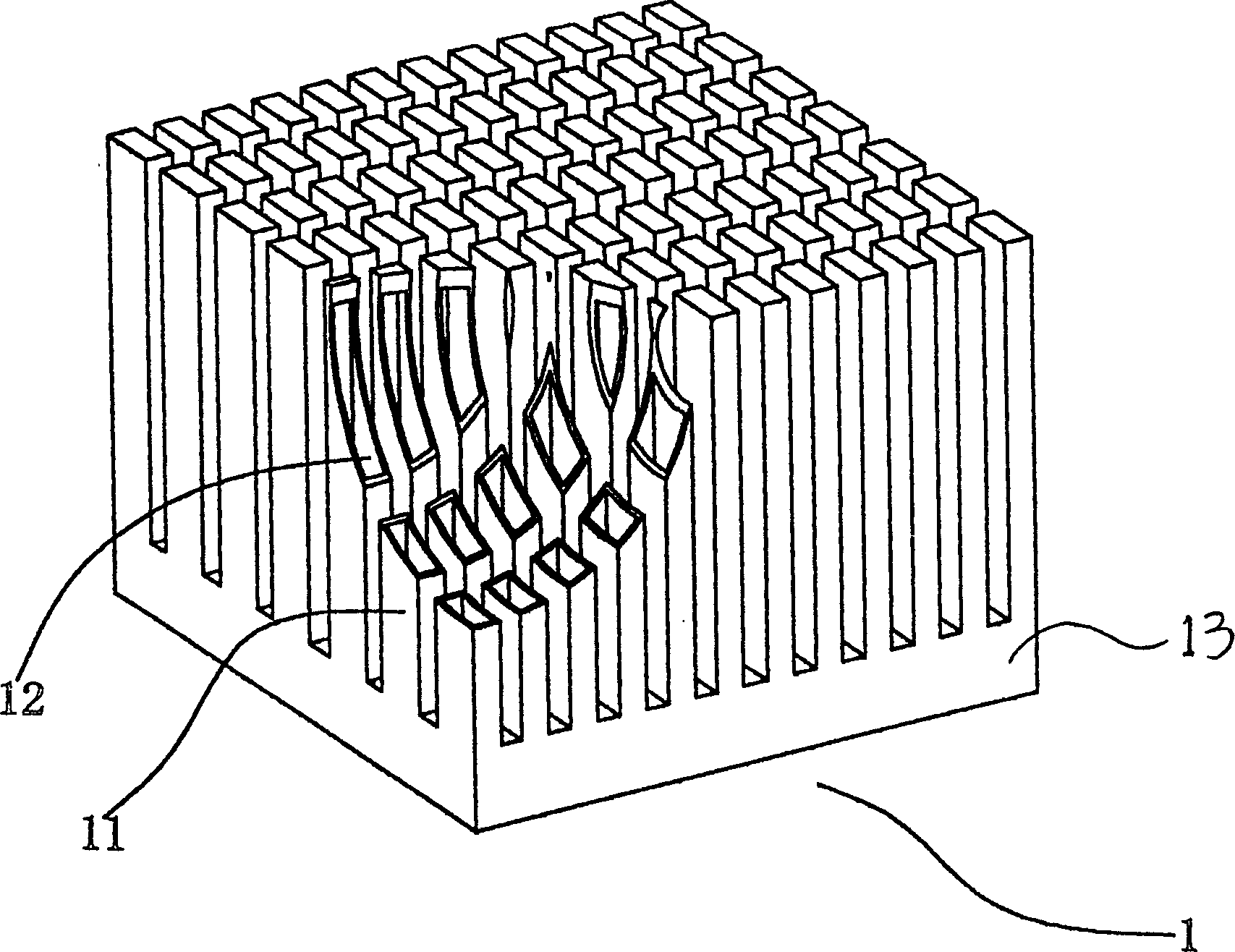

[0017] See attached figure 2 , which is a three-dimensional structure diagram of a specific embodiment of the present invention, which is mainly used for a heat sink on a chip of an integrated circuit, such as a heat sink used by a CPU in a computer mainframe, wherein the cross section of the heat sink 1 base 13 is rectangular , The upper part of the base 13 is provided with several raised square cylinders 12, and the cylinders 12 and the base 13 are solidly integrated. The purpose of setting the columns 12 is to increase the heat dissipation area of the radiator 1 to improve the heat dissipation efficiency.

[0018] See attached image 3 , both the base 13 of the radiator 1 and the inside of the column 12 are cavities 11 , and the cavity inside each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com