Hydrolic mechanism free electric motor servo system water turbine speed regulator

A servo system and hydraulic mechanism technology, applied in the direction of machines/engines, electromechanical devices, electric components, etc., can solve the problems of large static fuel consumption, complicated process, high maintenance costs, etc., and achieve no wearable parts, No pollution to the environment and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

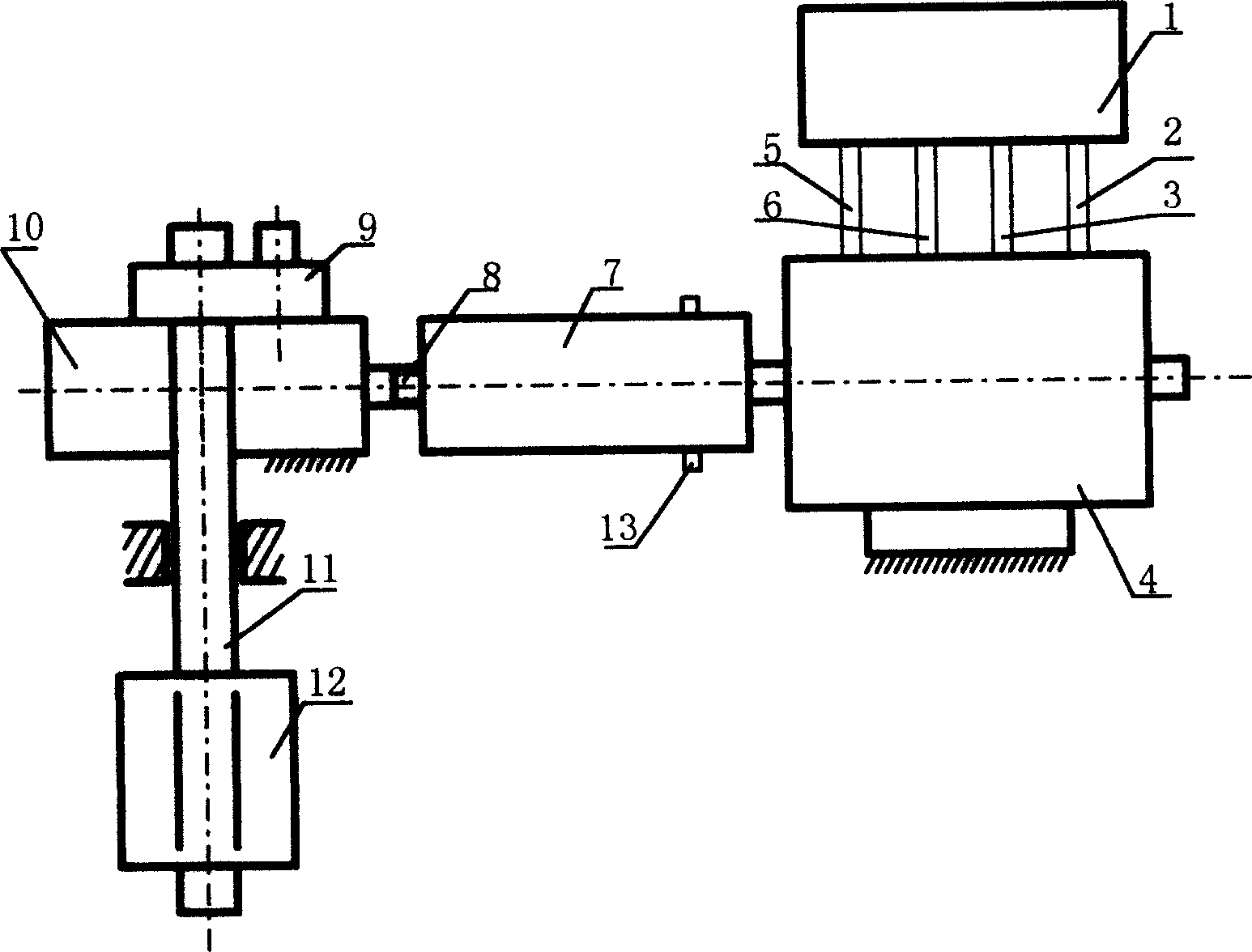

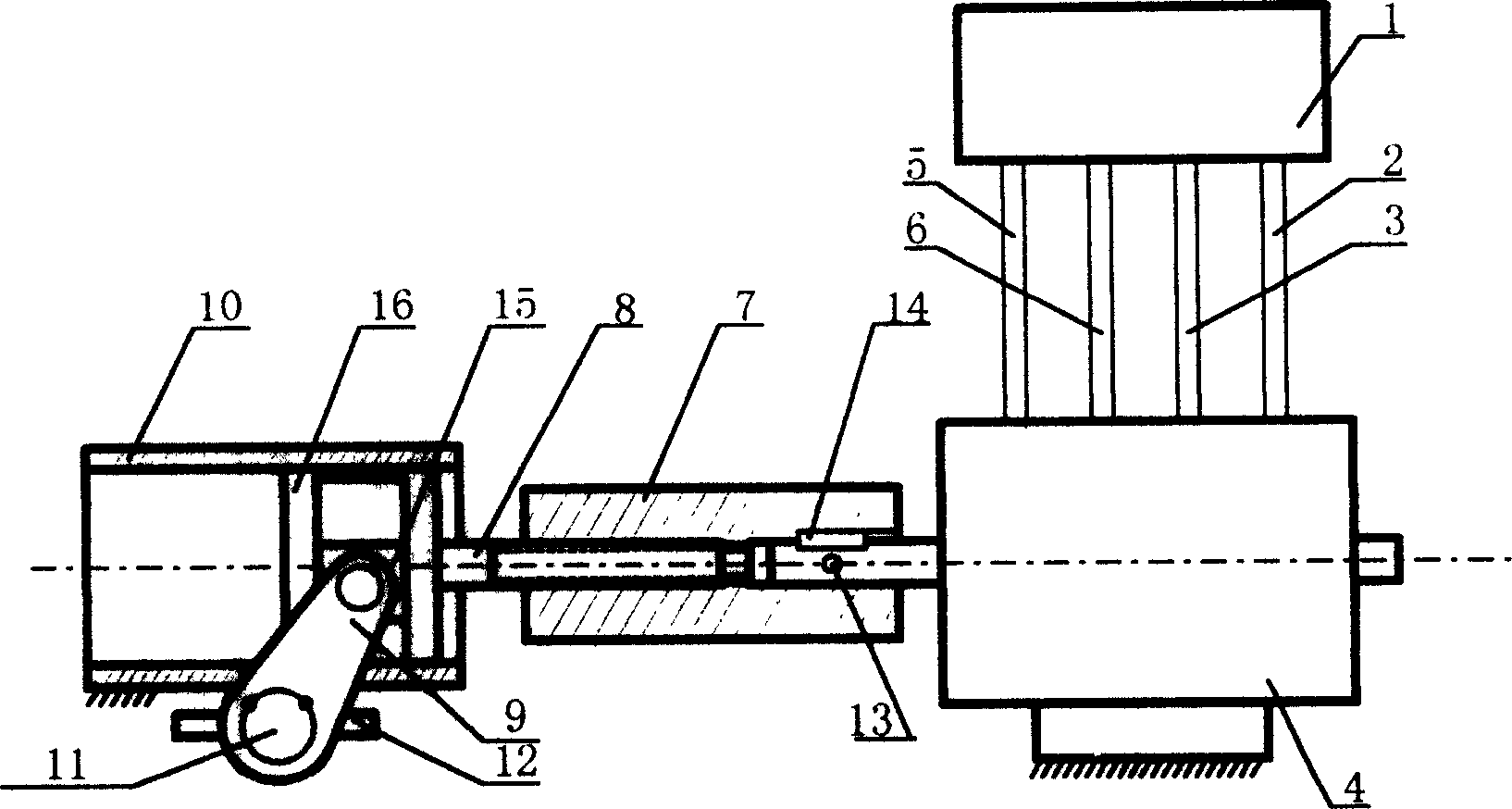

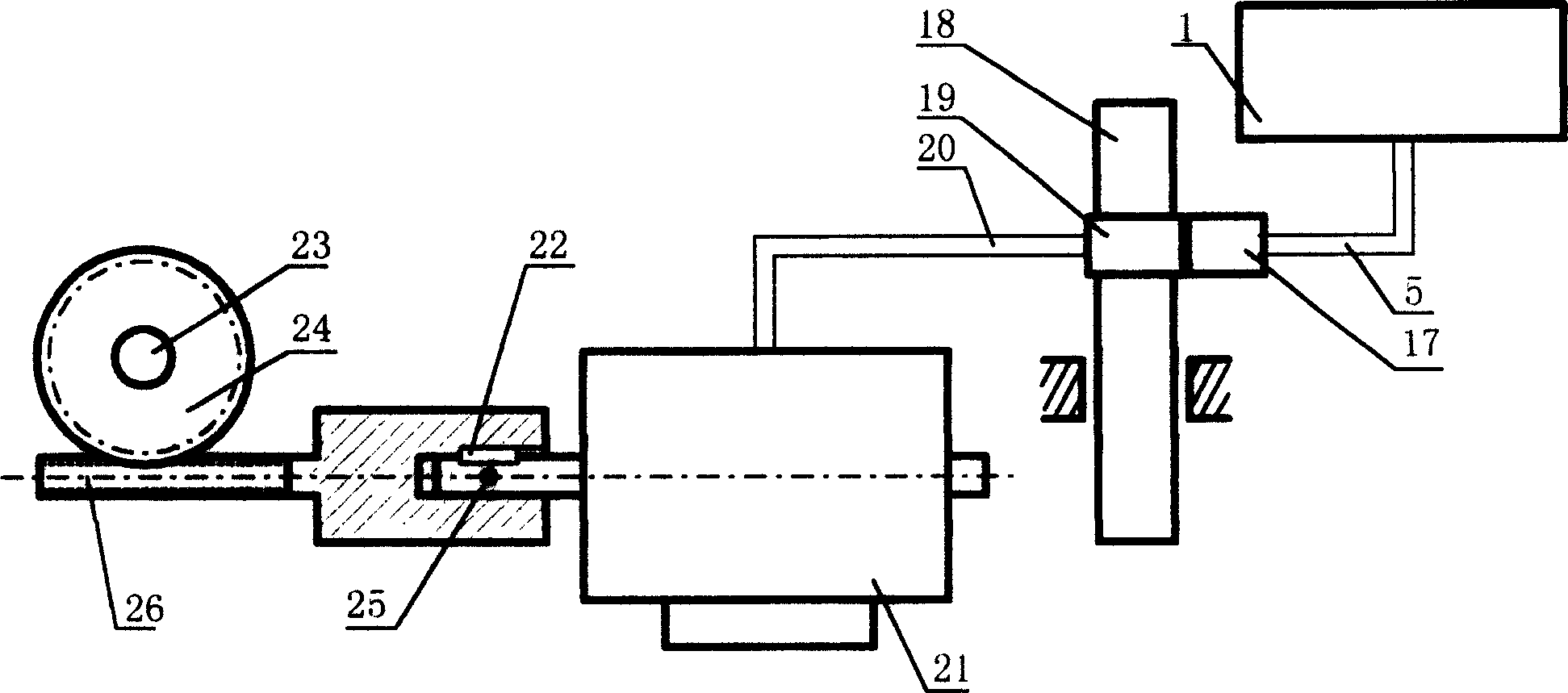

[0041] see figure 1 , figure 2 and Figure 5 , the electric servo driver 1 receives the control signal of the electric controller (A), and at the same time, also samples the relevant physical quantities of the guide vane motor 4 through the measurement harness 2 and the feedback harness 3, and obtains the feedback signal from the guide vane motor 4, for the above three Finally, the driving current is output to the vane motor 4 through the power drive harness 5 to make the motor 4 rotate. Since the motor 4 has a sampling circuit and a feedback circuit, it is necessary to control the power supply harness 6 to supply power to the motor 4. The screw sleeve 7 is rigidly connected with the output shaft of the motor 4 through the key 14 and the pin 13, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com