Punch press

A technology of punching machine and indenter, applied in the field of punching machine, can solve the problems of complex volume of guide device and driving device, difficulty in ensuring accuracy, and increase in energy consumption, etc., and achieve the effects of improving rigidity, improving centering accuracy, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

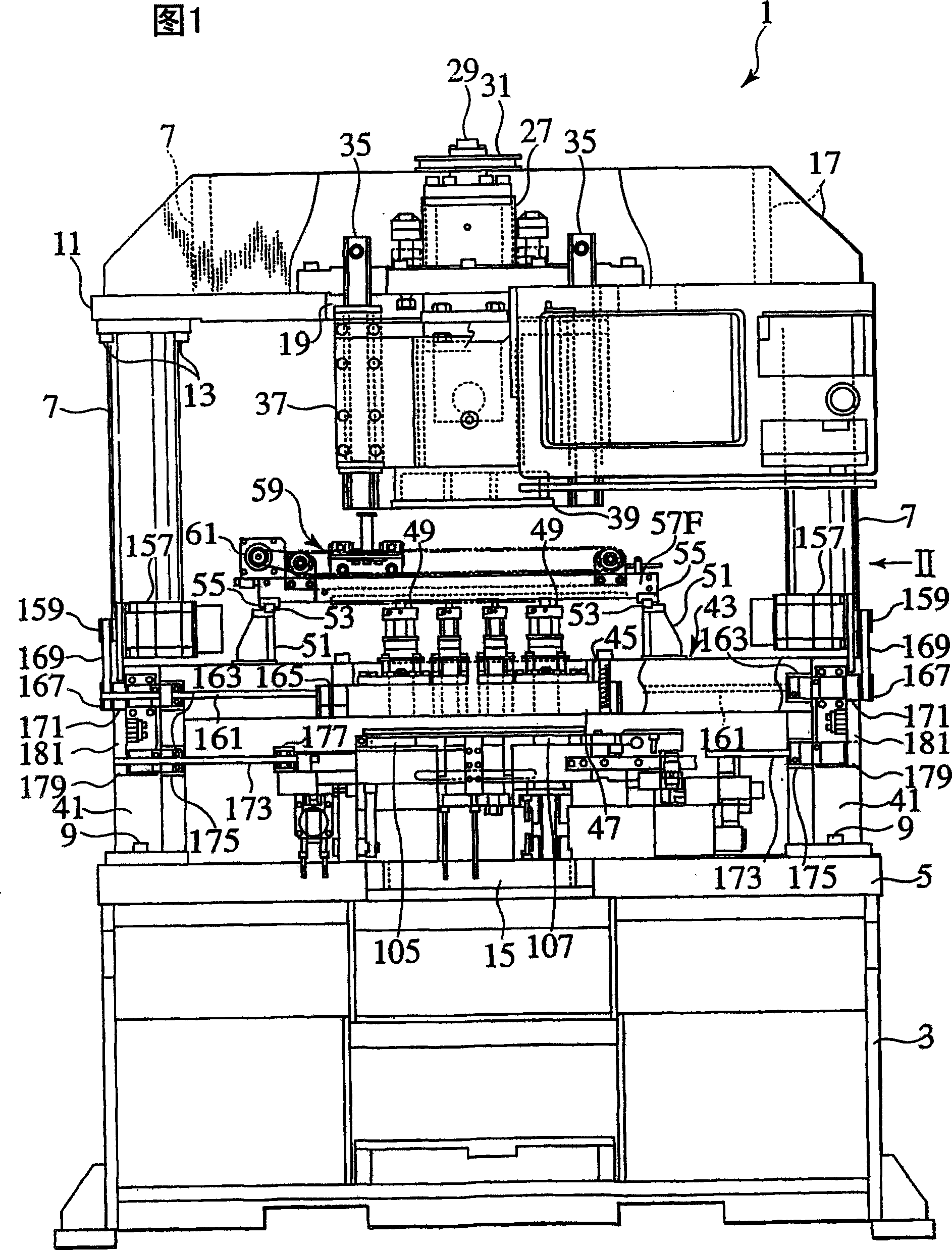

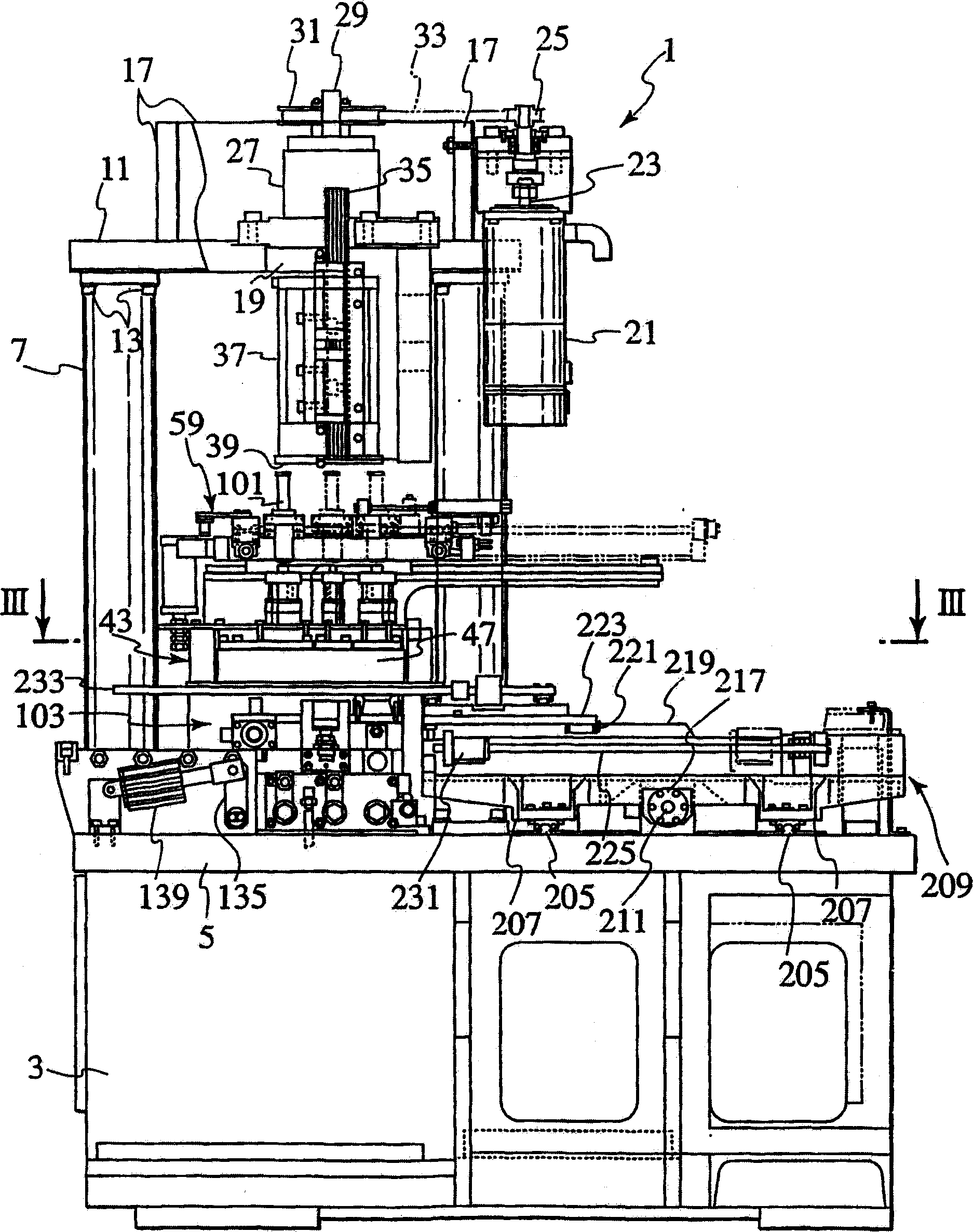

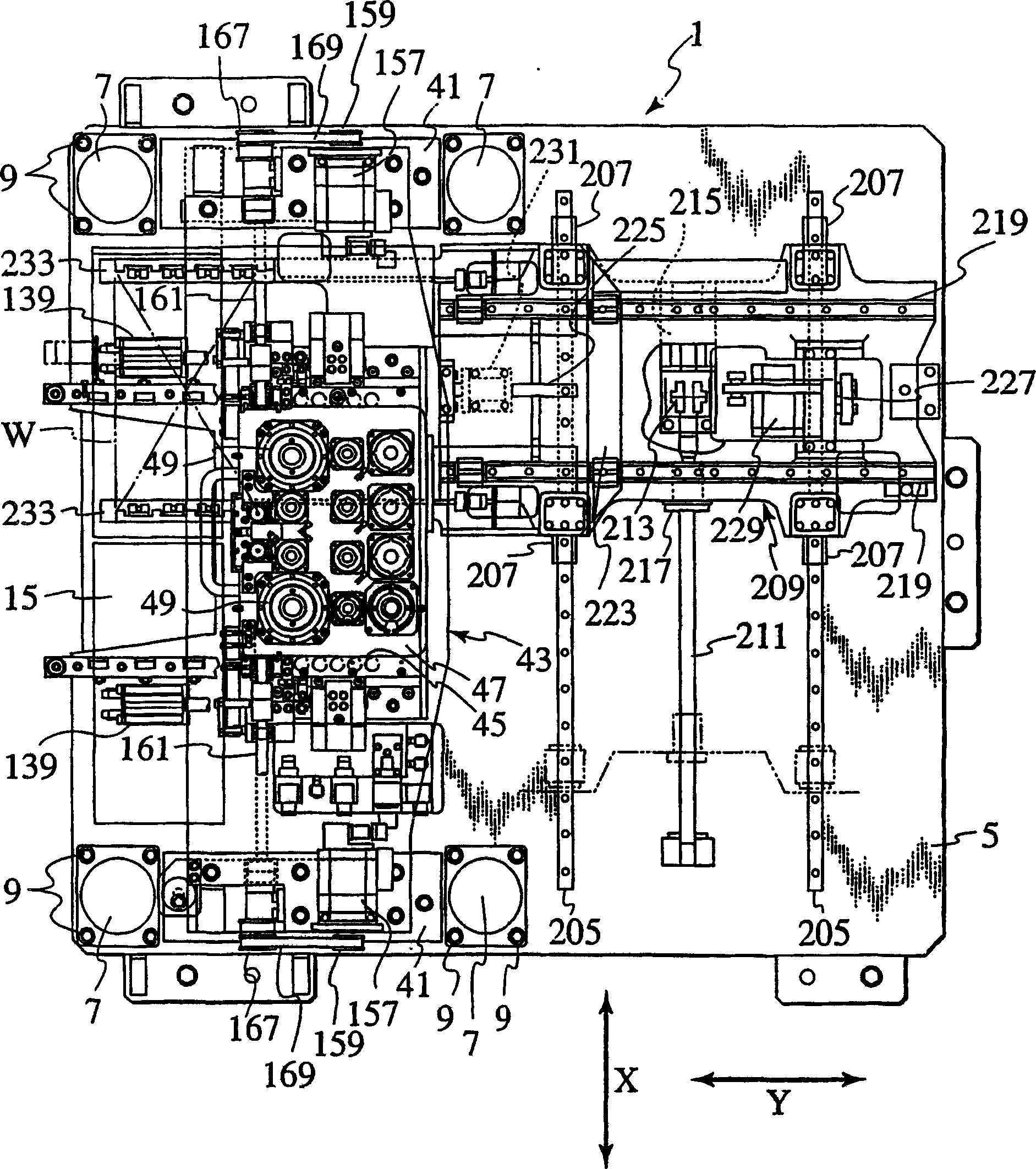

[0040] In Figure 1~ image 3In , the whole of the press machine 1 of the present invention is shown. In this high-precision press machine 1 , a structure is employed to suppress warping and vibration of the overall structure during processing as much as possible. That is, four thick pillars 7 with high rigidity are fixed by bolts 9 on the front, rear, left, and right ends of the thick plate bottom plate 5 provided on the base 3 , and the top plate frame 11 is fixed above the pillars 7 by bolts 9 . In addition, since the recessed portion 15 (see FIG. 7 ) is provided at the center of the front side of the bottom plate 5 , a space under the die holder described later is ensured, and the operator can easily perform die replacement operations.

[0041] On the upper surface of the roof frame 11, reinforcing ribs 17 are provided in front, rear, left, and right, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com