Punching/deforming tool for hundle-up device

A technology of stamping tools and strapping devices, which is applied to the parts of strapping machines, strapping objects, manufacturing tools, etc., and can solve problems such as uneven cutting force and unfavorable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

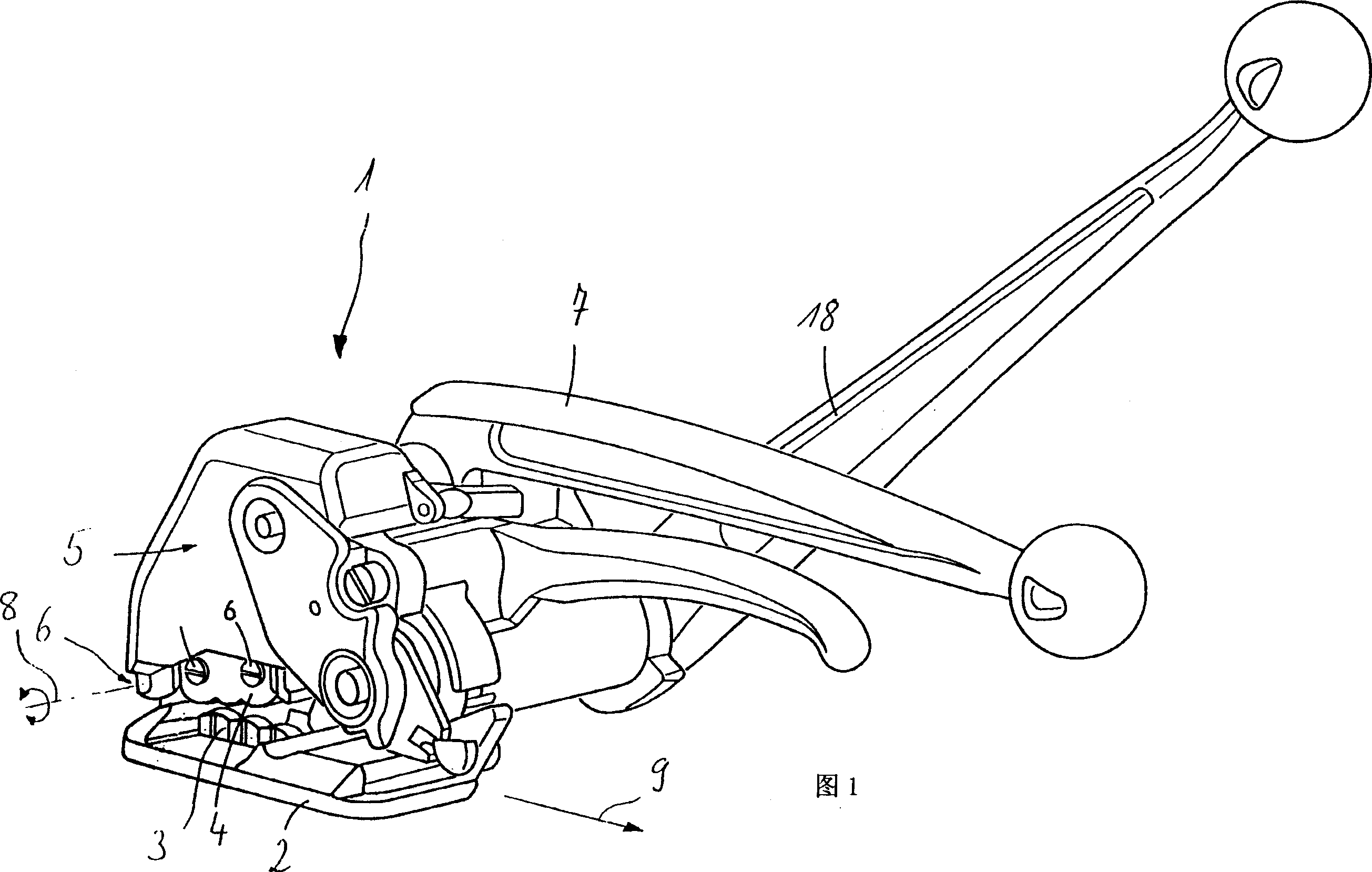

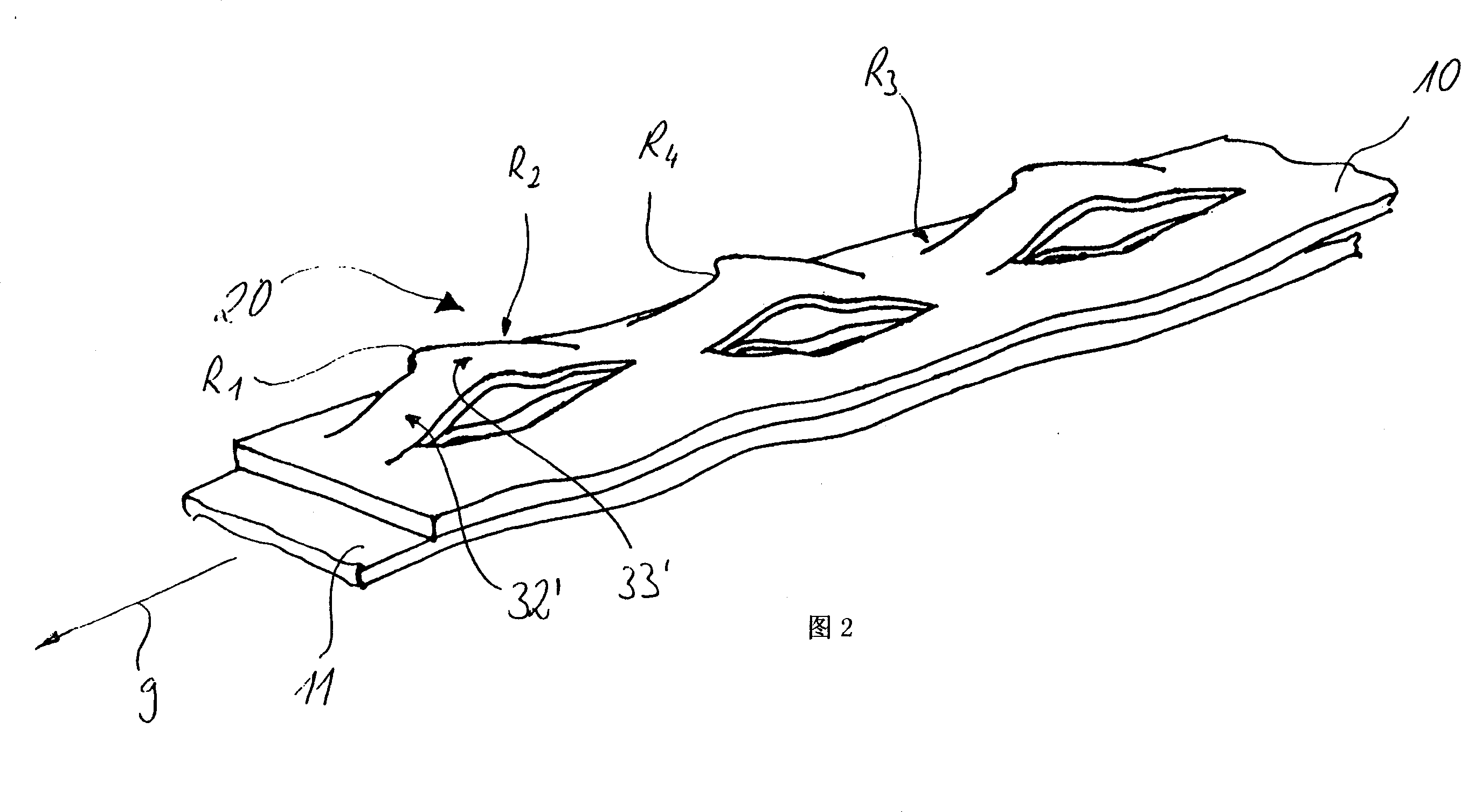

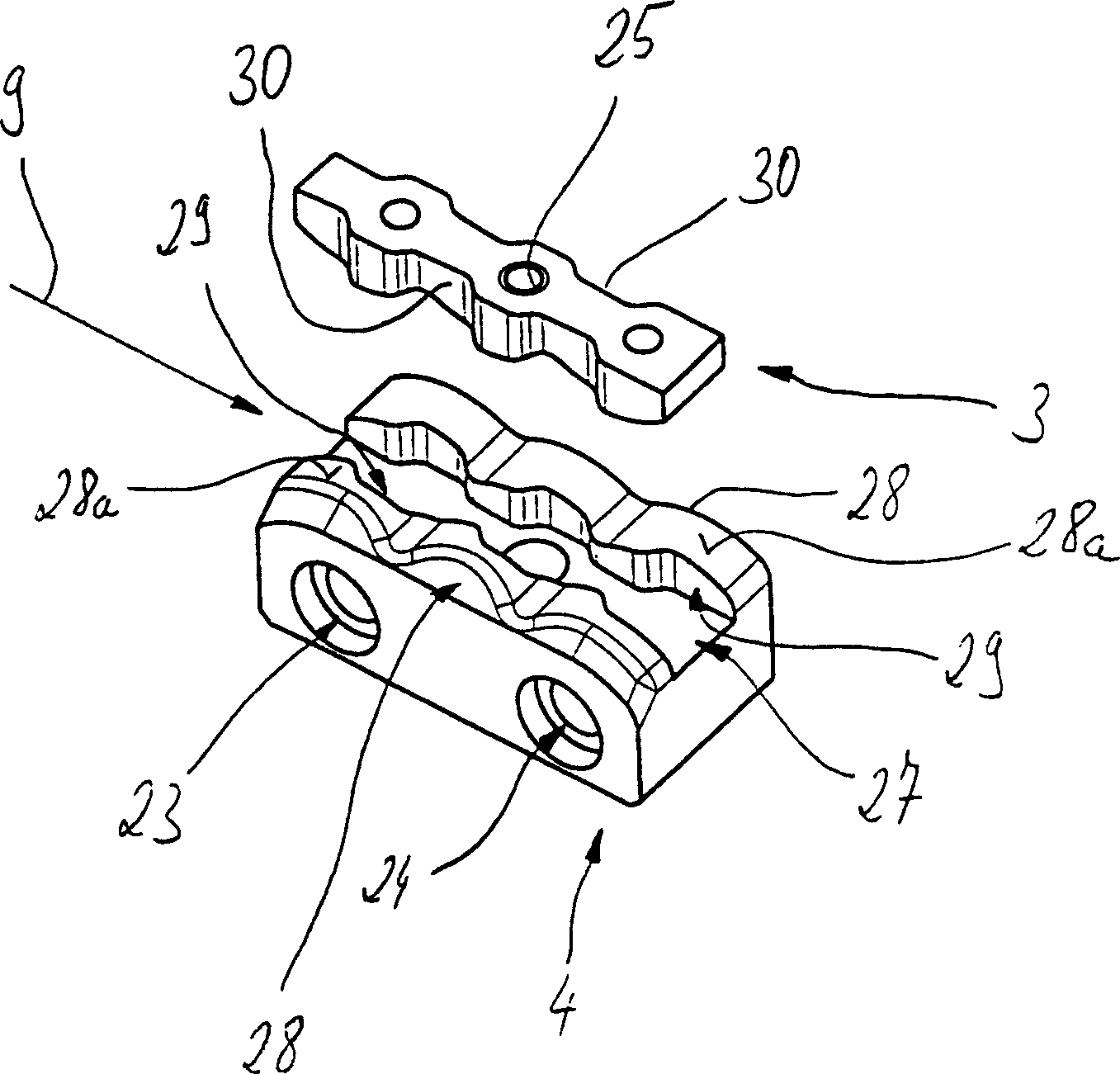

[0020] The manual strapping device shown in FIG. 1 is an example of this type of strapping device to which the present invention is applied. The strapping device is provided with a base plate 2, whose bottom surface is preferably flat, by which the strapping device is placed on the articles to be strapped. The single-part punch 3 is fixed in the base plate 2 . The one-part die 4 interacting with the punch 3 is secured in a die carrier 5 in a detachable manner. The die carrier 5 is pivotably hinged by a rotary hinge 6 (rotation shaft 8 of the hinge 6 is shown in the figure) mounted on the front end of the bottom plate 2 . By turning the lever 7 , the die carrier 5 can be rotated around the axis of rotation 8 in the direction of the bottom plate 2 and can be raised away from the bottom plate 2 . The rotating shaft 8 here basically faces the direction perpendicular to the extending direction 9 of the strapping. During the strapping process, the ends 10, 11 of the two strapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com