Method for treating waste water containing low concentration ammonium chloride

A treatment method, the technology of ammonium chloride, applied in the direction of heating water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problems of incomplete discharge, increase of potassium permeation, high cost, etc., and achieve resource utilization Utilization and clean production, solving environmental problems, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

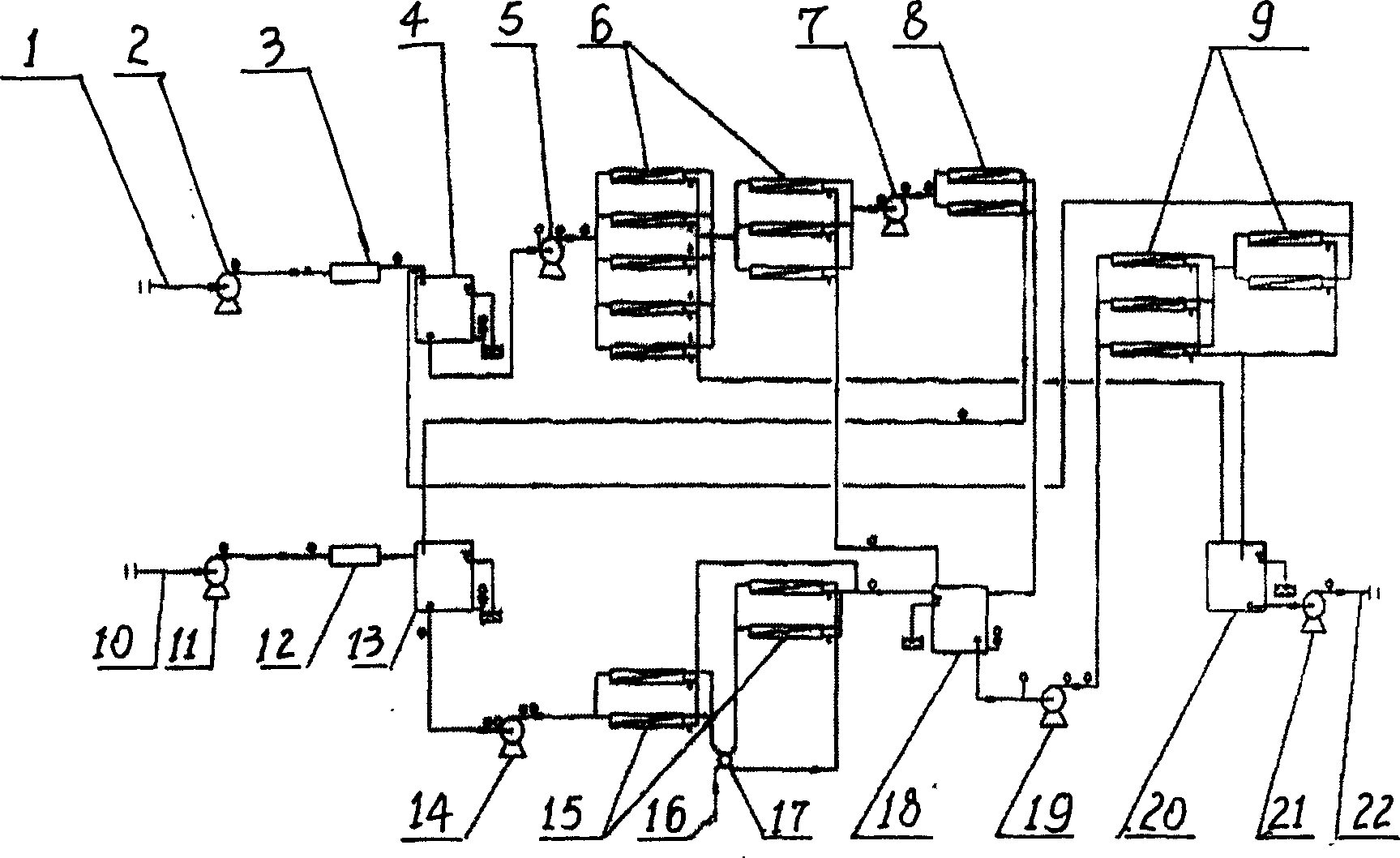

[0029] (1) Quality recovery of water: the ammonium chloride waste water produced in the potassium salt production system is divided into 0.01%~0.1%, 0.1%~0.4%, 0.1%~0.4% and 2% ~ 4%, ≥ 5.5% four kinds of water quality, collect waste water of the same water quality, mix them separately; use 0.1% ~ 0.4% low concentration wastewater ultrafiltration (or microfiltration) device 3 and 2% ~ 4% high concentration wastewater ultrafiltration The filtration (or microfiltration) device 12 pre-treats the wastewater to reduce the pollution of the reverse osmosis membrane.

[0030] (2) Reverse osmosis membrane concentration treatment of ammonium chloride wastewater, purified water reuse: the above-mentioned wastewater with a concentration of 0.01% to 0.1%, condensed water from the evaporation system and medium-pressure reverse osmosis 6, 8 out of purified water into low-pressure reverse osmosis The device 9 is uniformly processed, and the operating pressure is 1.3Mpa; the concentration is 0....

Embodiment 2

[0033]Water separation and recovery: the ammonium chloride wastewater generated in the potassium salt production system is divided into 0.01%~0.1%, 0.1%~0.4%, 2%~ 4%, ≥5.5% four kinds of water quality, collect the waste water of the same water quality, mix respectively; Adopt two sets of ultrafiltration (or microfiltration) devices to pretreat the waste water to reduce the pollution of the reverse osmosis membrane. Wherein, the two sets of ultrafiltration devices are 0.1%-0.4% low-concentration wastewater ultrafiltration device 3 and 2%-4% high-concentration wastewater ultrafiltration device 12 . The separated ammonium chloride wastewater enters the reverse osmosis membrane for concentration treatment.

[0034] Medium-pressure reverse osmosis devices 6 and 8 are divided into two stages of treatment, that is, for NH 4 Wastewater with a CL concentration of about 0.1% is treated by the first stage of reverse osmosis6, and the design recovery rate is about 80%. After this stage o...

Embodiment 3

[0039] The ammonium chloride wastewater with a concentration of about 0.1% is concentrated to 0.4-0.5% by the low-pressure reverse osmosis device 9, and the purified water is returned to the production system as process pure water for reuse (if it is necessary to improve the quality of the purified water, it can be considered to add a low-pressure or super low pressure reverse osmosis unit). Concentrated water can be used for other process treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com