Lead paste recycling device of waste pole plate and lead paste recycling method

A recovery device and collection device technology, applied in the field of waste electrode plate lead paste recovery device, can solve the problems of incomplete recovery, phase change of lead paste, oxidation, etc., achieve complete recovery, ensure stability and consistency, and process efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

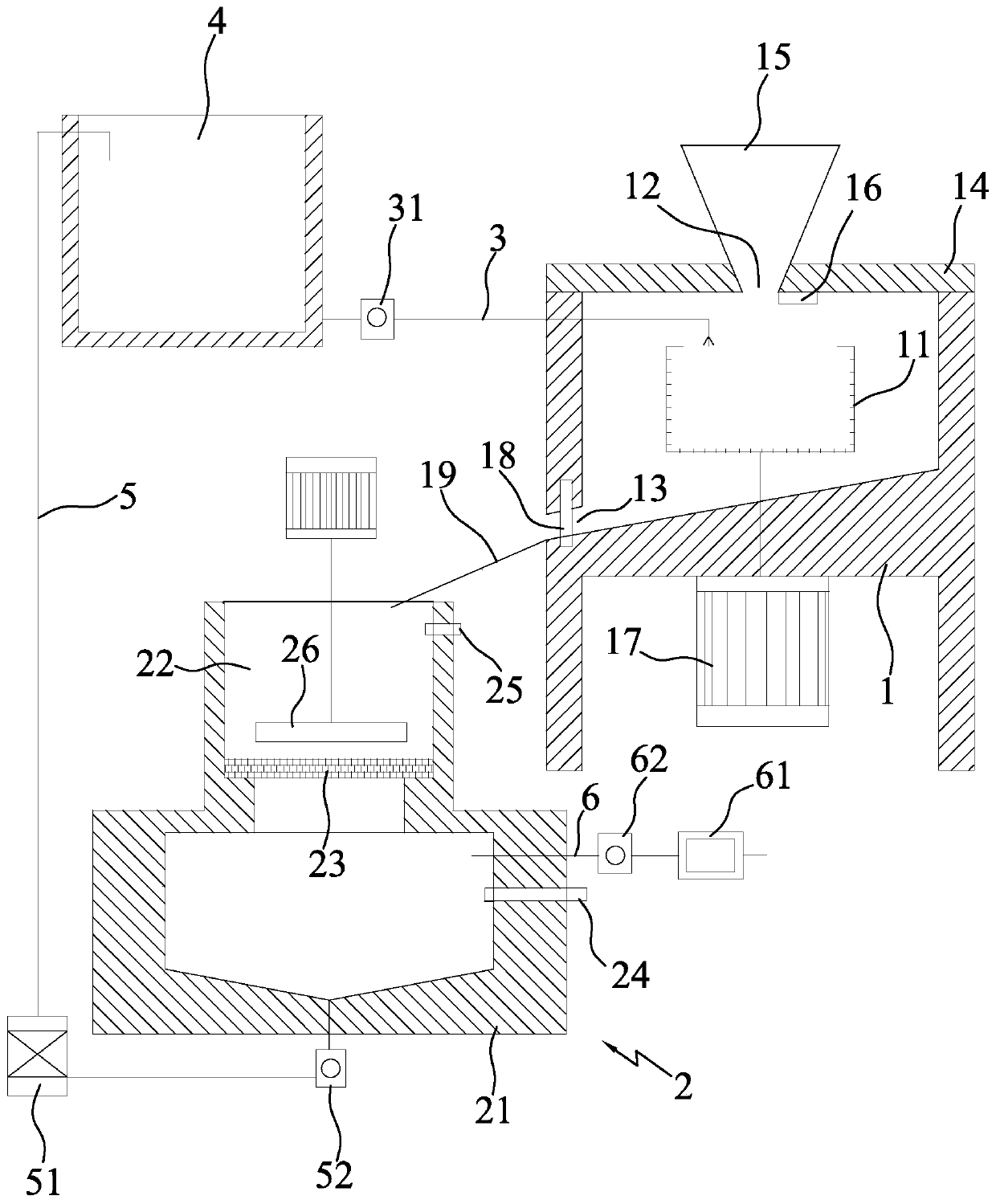

[0024] Such as figure 1 As shown, a waste plate lead paste recycling device includes a centrifugal device 1 and a lead slime collecting device 2 connected to the centrifugal device 1 . The centrifugal device 1 has a feed port 12 and a mud outlet 13. The centrifugal device 1 has a centrifugal barrel 11 inside, and the side wall and the bottom surface of the centrifugal barrel 11 have lead mud holes, and the diameter of the lead mud holes is 5-8mm. Centrifugal barrel 11 is driven to rotate by motor 17 .

[0025] The top surface of the centrifugal device 1 is open, and has a loam cake 14 covering the opening. The feed port 12 is located on the loam cake 14 and is positioned directly above the centrifuge bucket 11. Feeding bin 15. The bottom surface of the upper cover 14 is provided with a photoelectric sensor 16 for detecting waste plates. The setting of the upper cover 14 facilitates opening the upper cover 14 after a centrifugation is completed, and the remaining grids in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com