Inflating valve suitable for new energy automobile and production process of inflating valve

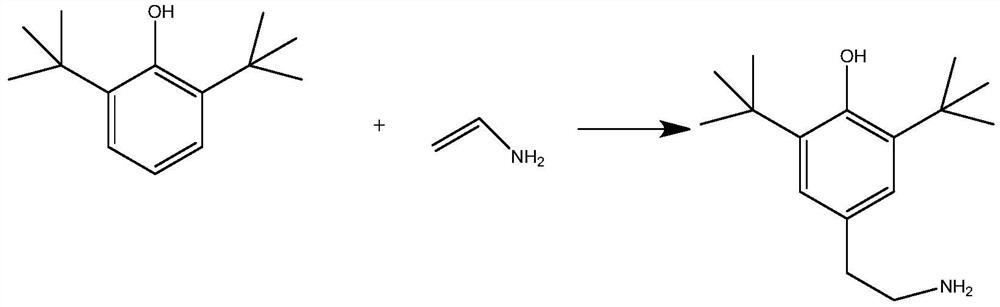

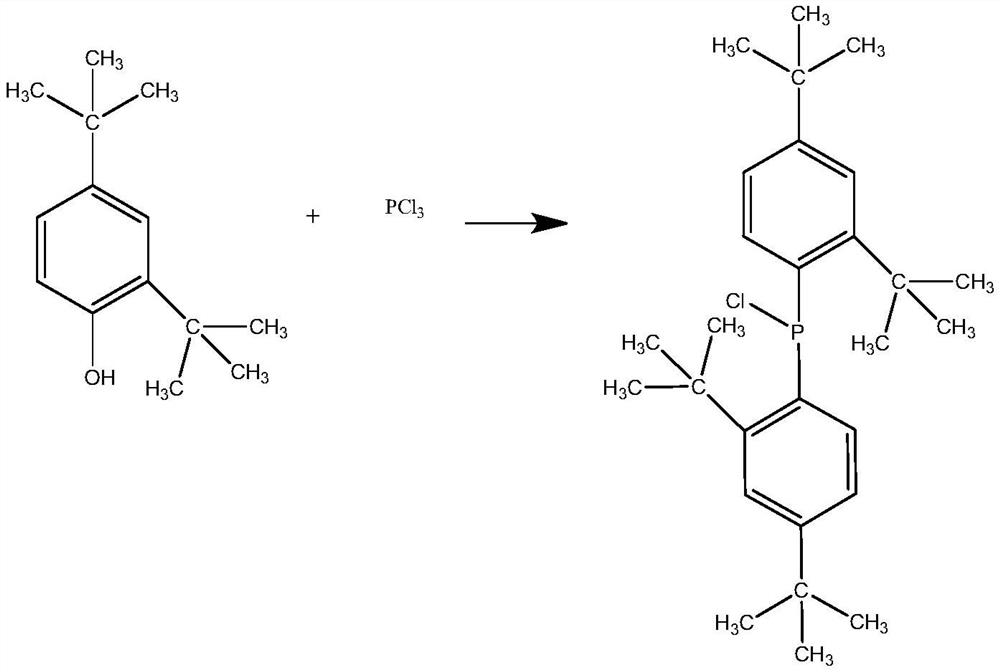

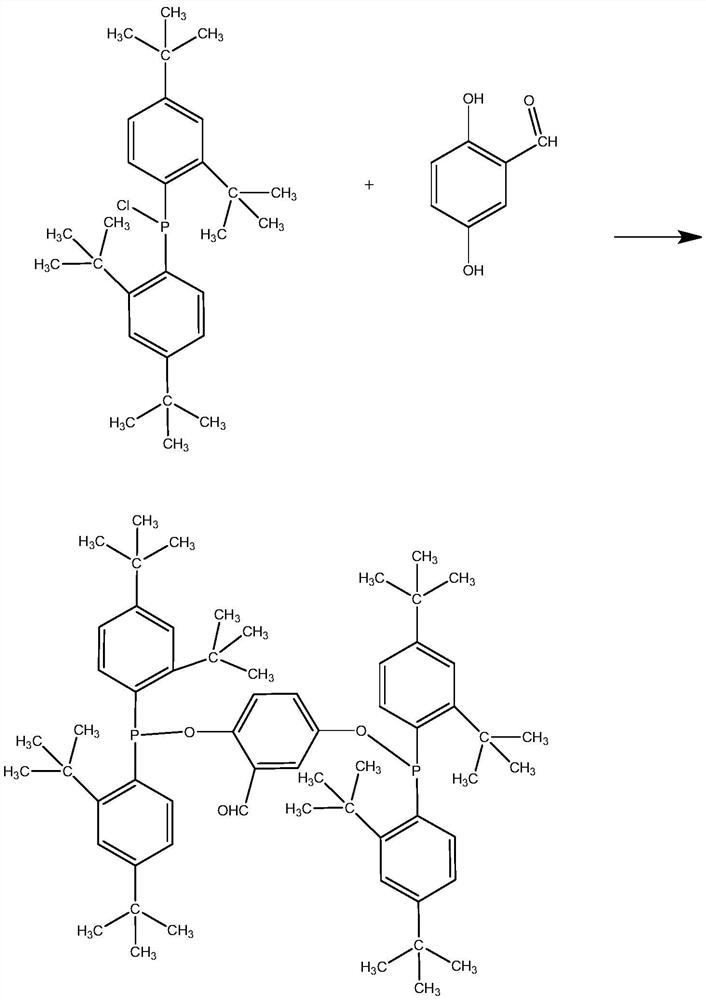

A technology for new energy vehicles and production processes, which is applied in the direction of valves used for inflation, functional valve types, compounds of elements of Group 5/15 of the periodic table, etc., and can solve problems such as insufficient adhesion and insufficient anti-aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A valve suitable for new energy vehicles and its production process, including a metal nozzle body and a rubber material, the rubber material is composed of the following raw materials in parts by weight: 50 parts of ethylene propylene rubber, 40 parts of carbon black, 5 parts of white carbon black, softened 20 parts of plasticizer, 2 parts of active agent, 1 part of anti-aging agent, 1 part of vulcanizing agent, 1 part of accelerator, 2 parts of cobalt salt, 2 parts of pyrogallic acid; wherein, softening plasticizer is paraffin oil, active agent It is stearic acid, the vulcanizing agent is sulfur, and the accelerator is TMTD;

[0033] A production process suitable for a valve of a new energy vehicle, comprising the following steps:

[0034] The first step: Pretreatment of the surface of the valve: first prepare a mixed acid solution and add zinc oxide to the mixed acid solution, the mass ratio of the mixed acid solution to zinc oxide is 20:0.5; add the metal nozzle bod...

Embodiment 2

[0038] A valve suitable for new energy vehicles and its production process, including a metal nozzle body and a rubber material, the rubber material is composed of the following raw materials in parts by weight: 55 parts of ethylene-propylene rubber, 45 parts of carbon black, 8 parts of white carbon black, softened 25 parts of plasticizer, 3 parts of active agent, 2 parts of anti-aging agent, 2 parts of vulcanizing agent, 2 parts of accelerator, 4 parts of cobalt salt, 3 parts of pyrogallic acid; wherein, softening plasticizer is paraffin oil, active agent It is stearic acid, the vulcanizing agent is sulfur, and the accelerator is TMTD;

[0039] A production process suitable for a valve of a new energy vehicle, comprising the following steps:

[0040]The first step: Pretreatment of the surface of the valve: first prepare a mixed acid solution and add zinc oxide to the mixed acid solution, the mass ratio of the mixed acid solution to zinc oxide is 30:0.8; add the metal nozzle b...

Embodiment 3

[0044] A valve suitable for new energy vehicles and its production process, including a metal nozzle body and a rubber material, the rubber material is composed of the following raw materials in parts by weight: 60 parts of ethylene-propylene rubber, 50 parts of carbon black, 10 parts of white carbon black, softened 30 parts of plasticizer, 5 parts of active agent, 3 parts of anti-aging agent, 3 parts of vulcanizing agent, 3 parts of accelerator, 5 parts of cobalt salt, 4 parts of pyrogallic acid; wherein, softening plasticizer is paraffin oil, active agent It is stearic acid, the vulcanizing agent is sulfur, and the accelerator is TMTD;

[0045] A production process suitable for a valve of a new energy vehicle, comprising the following steps:

[0046] The first step: pretreatment of the surface of the valve: first prepare a mixed acid solution and add zinc oxide to the mixed acid solution, the mass ratio of the mixed acid solution to zinc oxide is 40:1.0; add the metal nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com