Process and device for recovering solvent-containing tail gas in production of control sustained-release fertilizer with envelope

A film-coated controlled-release fertilizer and solvent-containing technology, which is applied in separation methods, chemical instruments and methods, vapor condensation, etc., can solve problems such as solvent waste and unfavorable environmental protection, and achieve the effect of meeting environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

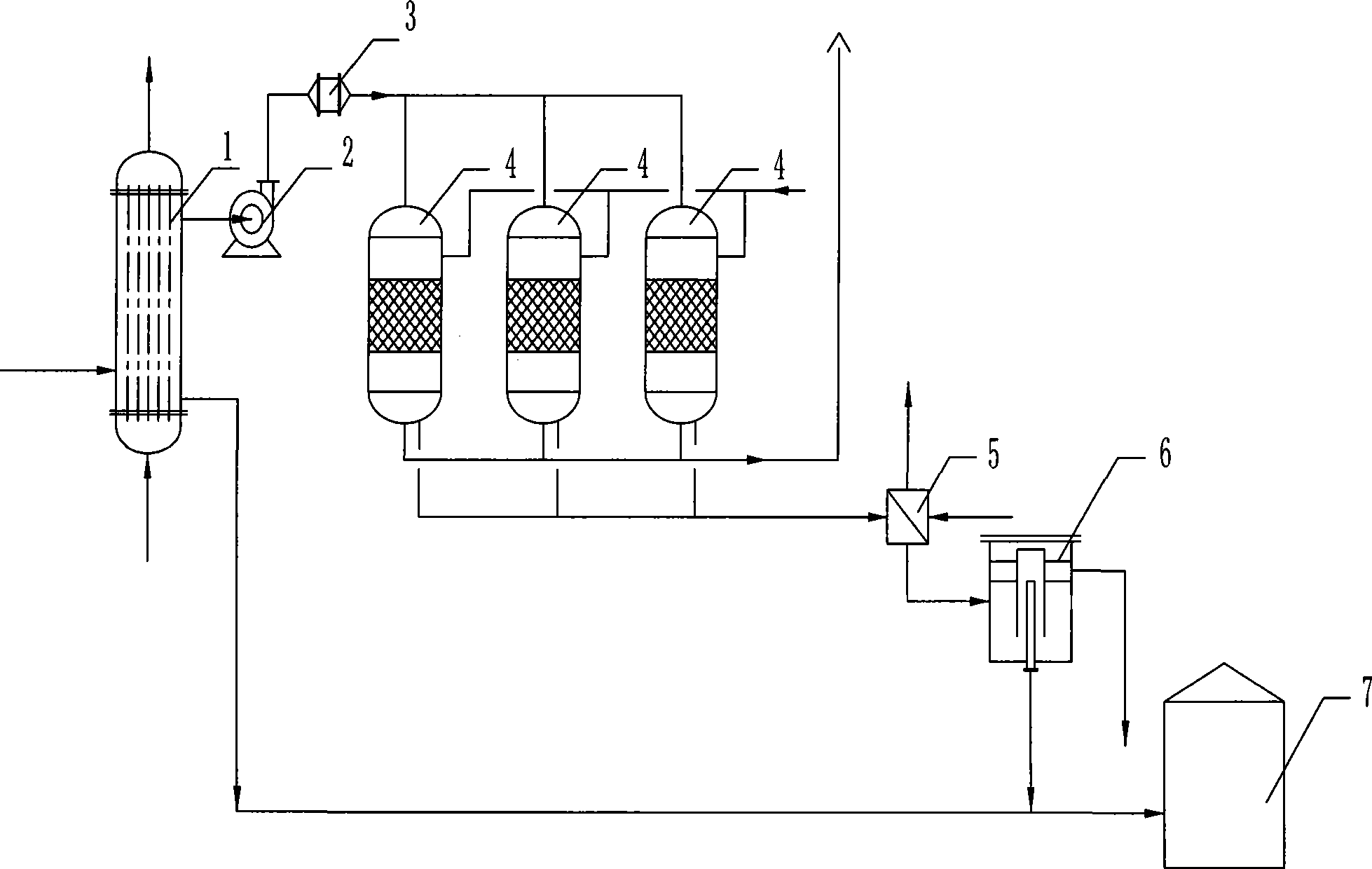

[0013] Such as figure 1 As shown, the solvent-containing tail gas recovery device in the production of coated controlled-release fertilizers consists of a circulating water condenser 1, a fan 2, a filter 3, three parallel adsorption tanks 4, a cooler 5, a layered tank 6 and a recovery tank 7, the tail gas outlet of the circulating water condenser 1 communicates with the air inlet of the adsorption tank 4 through the fan 2 and the filter 3, the condensate outlet of the circulating water condenser 1 communicates with the recovery tank 7, and the adsorption The condensate outlet of tank 4 communicates with recovery tank 7 through cooler 5 and stratification tank 6 .

Embodiment 2

[0015] Utilize the device described in embodiment 1 to carry out the recovery of solvent tail gas in the production of coated controlled release fertilizer, the specific operation steps are:

[0016] A. After collecting the solvent tail gas in the production of coated controlled-release fertilizer, it is cooled to below 40°C through the circulating water condenser 1, and part of the solvent is recovered, and the tail gas is pressurized by the fan 2, and the solid impurities are removed by the filter 3, and then sent to the adsorption tank 4;

[0017] B. In the adsorption tank 4, the solvent therein is adsorbed by activated carbon, and the purified gas is discharged directly. A total of three adsorption tanks 4 work in parallel, one of which is for adsorption, and the other two are for desorption and drying, and are switched at regular intervals;

[0018] C. When the adsorption tank 4 is desorbed, water vapor is introduced, and the water vapor passes through the activated carb...

Embodiment 3

[0019] Example 3: 2000m 3 / h Tail gas recovery of tetrachlorethylene.

[0020] A. Set 2000m 3 / h The tail gas containing tetrachlorethylene in the production of coated controlled-release fertilizer is collected and first cooled to below 40°C through the circulating water condenser 1, and the condensed part of tetrachlorethylene is recovered, and the tail gas is then used by B9-19-4.5A fan 2 Pressurize and remove solid impurities through a 100-mesh filter 3 and send it to an adsorption tank 4 with 6 tons of active carbon;

[0021] B. In the adsorption tank 4, the tetrachlorethylene in the tail gas is adsorbed by activated carbon, and the purified gas is discharged directly. A total of three adsorption tanks 4 work in parallel, one of which is for adsorption, and the other two are for desorption and drying, and are switched at regular intervals;

[0022] C. When the adsorption tank 4 is desorbed, water vapor is introduced, and the water vapor passes through the activated carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com