Solution to edge effect of two-phase gas-liquid flow capacitive sensor

A capacitive sensor, gas-liquid two-phase flow technology, applied in the direction of material capacitance, etc., can solve the problems of difficult to determine the volume of fluid sensitive space, uneven sensitive field, measurement error, etc., and achieve simple structure, low cost and high sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

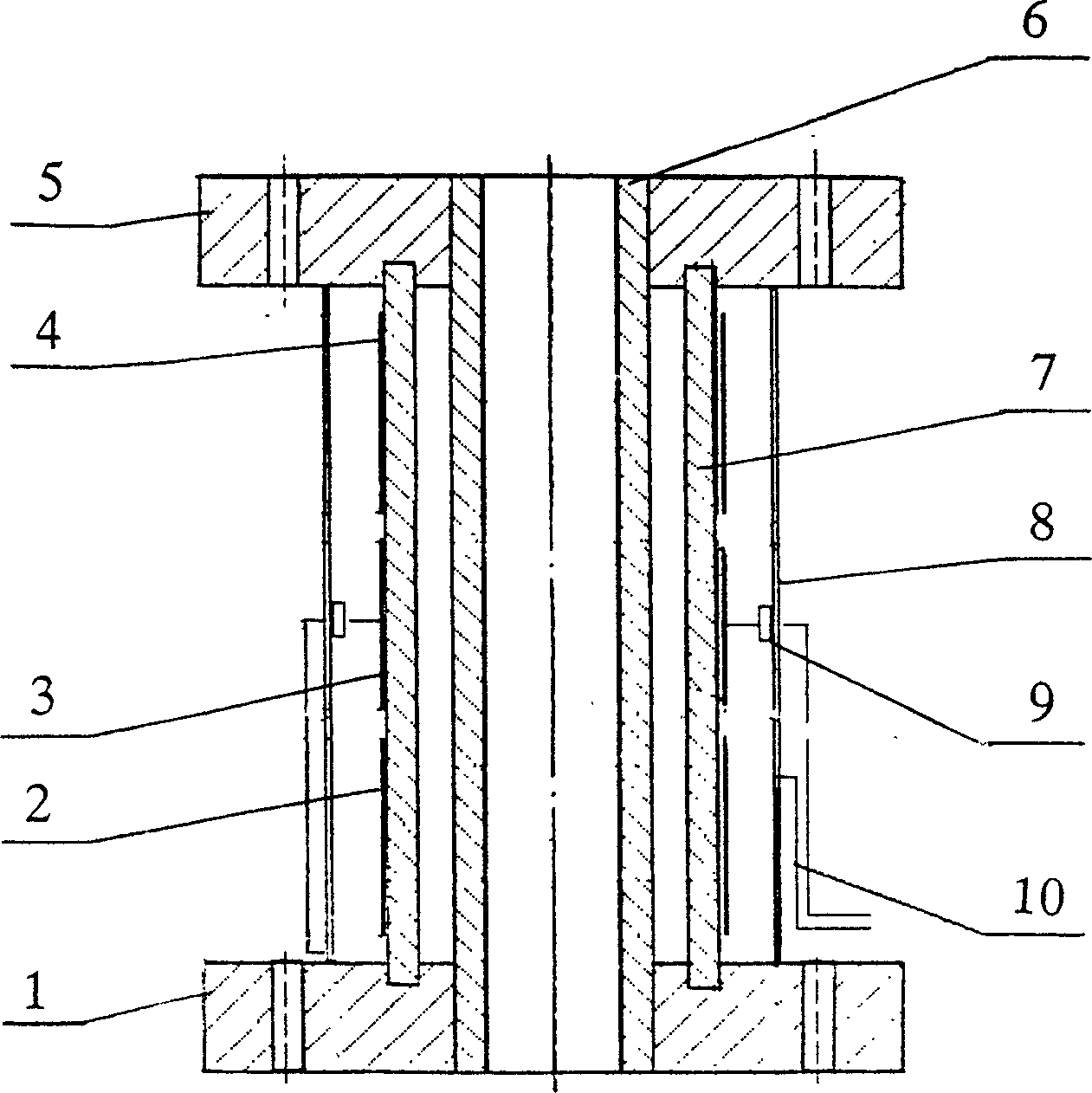

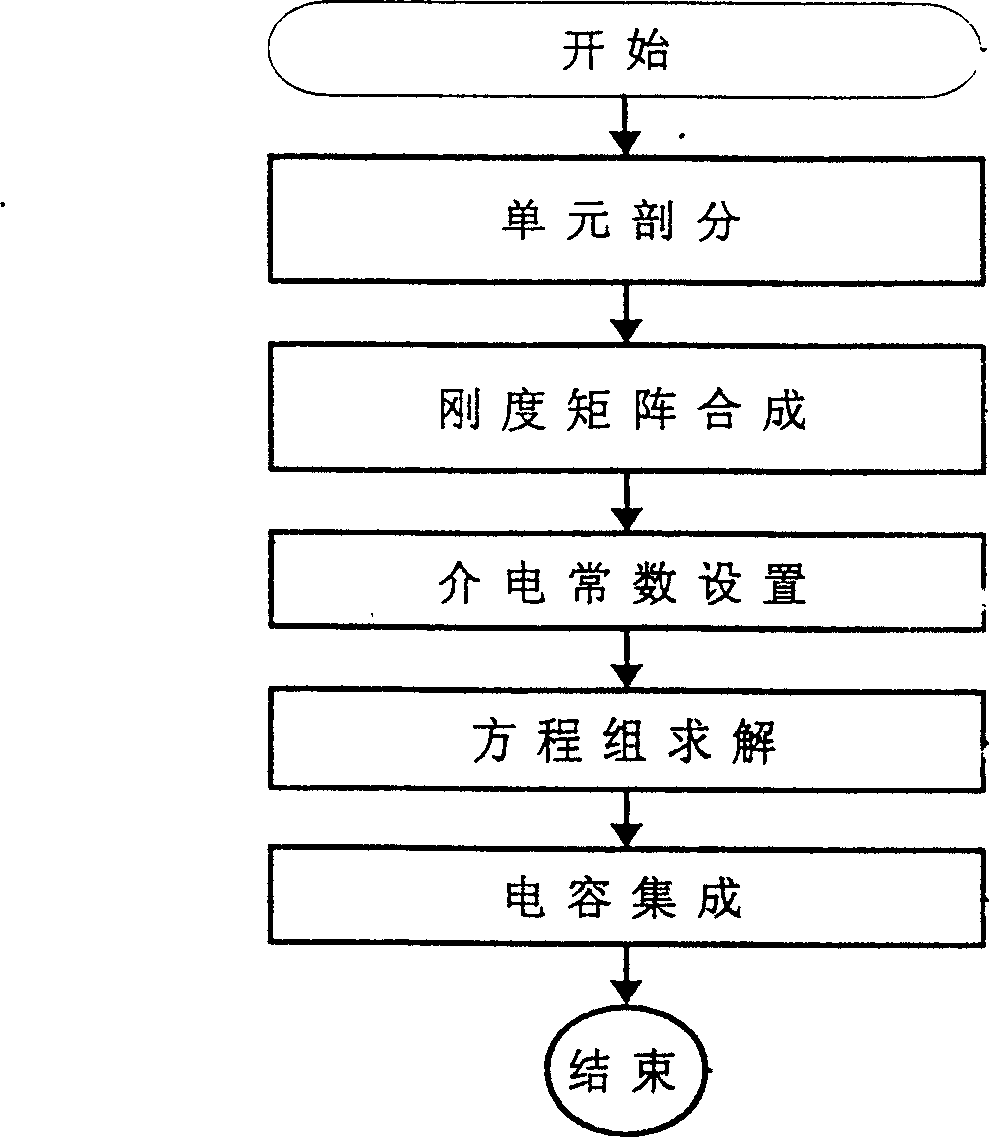

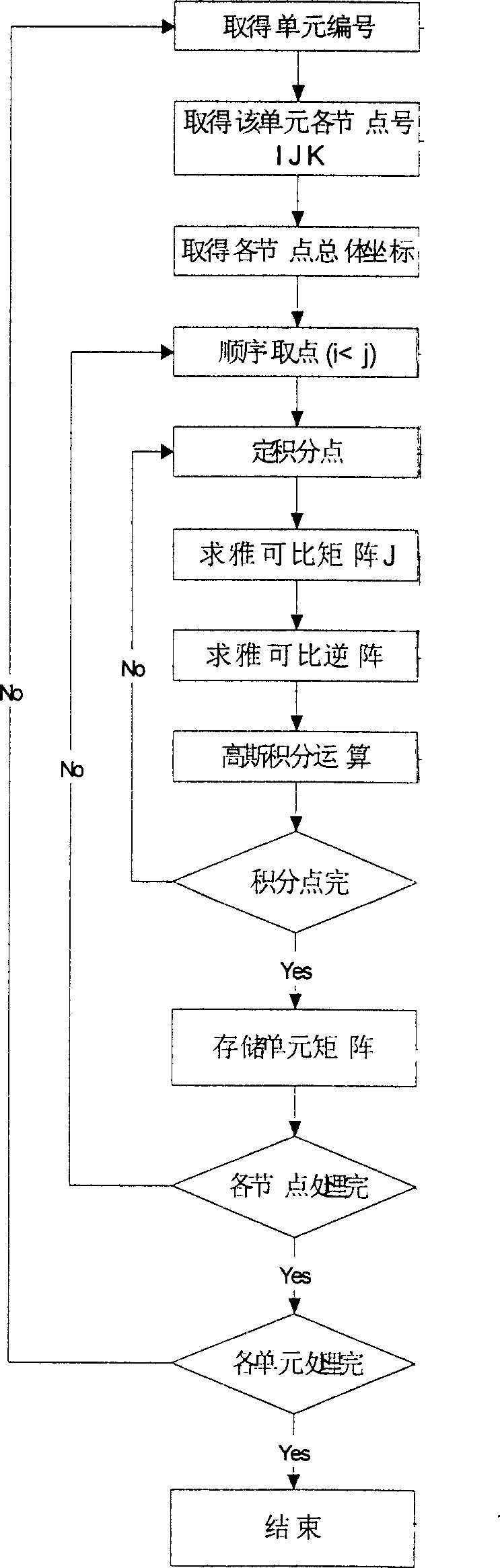

[0012] As shown in the figure, the technical solution of the present invention and the solution to the edge effect of the capacitive sensor are further described in conjunction with the embodiments. A solution to the edge effect of a gas-liquid two-phase flow capacitive sensor. The two ends of the connecting pipe 6 of the sensor are respectively fixed with a flange 1 and a flange 5, and the pole plate tube 7 and the galvanized plate shield 8 are respectively fixed. Between the flange 1 and the flange 5, the capacitor plate 3 is arranged on the outer circle in the middle of the plate tube 7, and the two sides of the outer circle are respectively provided with a protective plate 2 and a protective plate 4, and the capacitor plate 3 The lead wire 9 of the capacitor plate is connected, and the shield cover 8 is connected with the lead wire 10 of the shield cover. The main parameters of the protective plate L and the opening angle θ of the arc-shaped plate are optimized and determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com