Half screw pile and its pile forming method thereof

A technology of screw piles and piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of soil extraction and mud pollution, and achieve the effects of construction noise pollution, no construction, and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

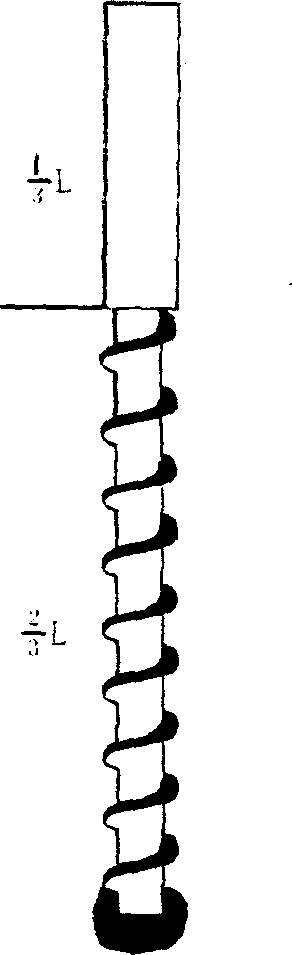

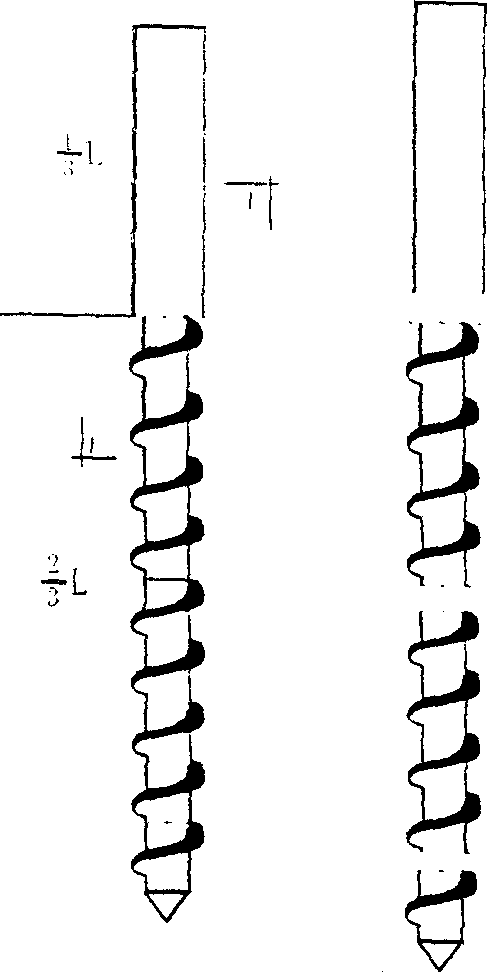

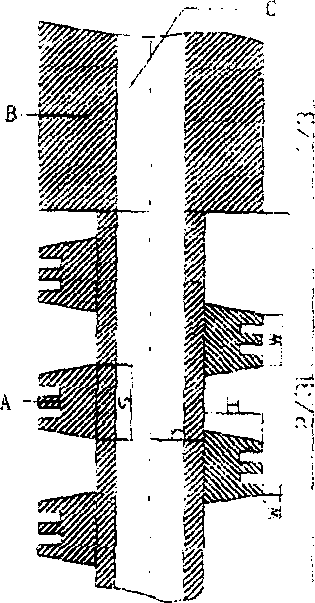

[0027] The cast-in-place semi-screw pile is composed of two parts, the upper part is a linear structure, the lower part is a screw structure, the linear structure accounts for 1 / 3 of the total pile length, and the screw structure accounts for 2 / 3 of the total pile length. One-time forming construction of screw drill pipe drilling rig. The specific steps are as follows: ①. Use a special semi-screw pile drilling rig to rotate clockwise to form a hole to the design depth;

[0028] ②Use the pump to squeeze the concrete out of the bottom of the drill pipe, and rotate the drill pipe counterclockwise to lift the drill pipe to maintain the pressure difference between the drill pipe and the soil without interrupting the concrete. Rotate counterclockwise to lift and pump the concrete to form the lower screw Type pile;

[0029] ③ After the drill pipe rises close to the level of the soft soil bottom, it is changed from rotating to non-rotating straight lifting, until the upper pile is in...

Embodiment 2

[0032] The prefabricated semi-screw pile is composed of two parts, the upper part is a linear structure, the lower part is a screw structure, the linear structure accounts for 1 / 3 of the total pile length, and the screw structure accounts for 2 / 3 of the total pile length. Segment forming welding or bonding, using a high-frequency vibrator to partially liquefy the soil, so that the pile is gradually sunk during the liquefaction of the soil to form a half-screw pile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com