Operating-fluid container

A technology for working fluids and containers, which can be used in household components, substructures, applications, etc., and can solve problems such as occupying the internal volume of containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

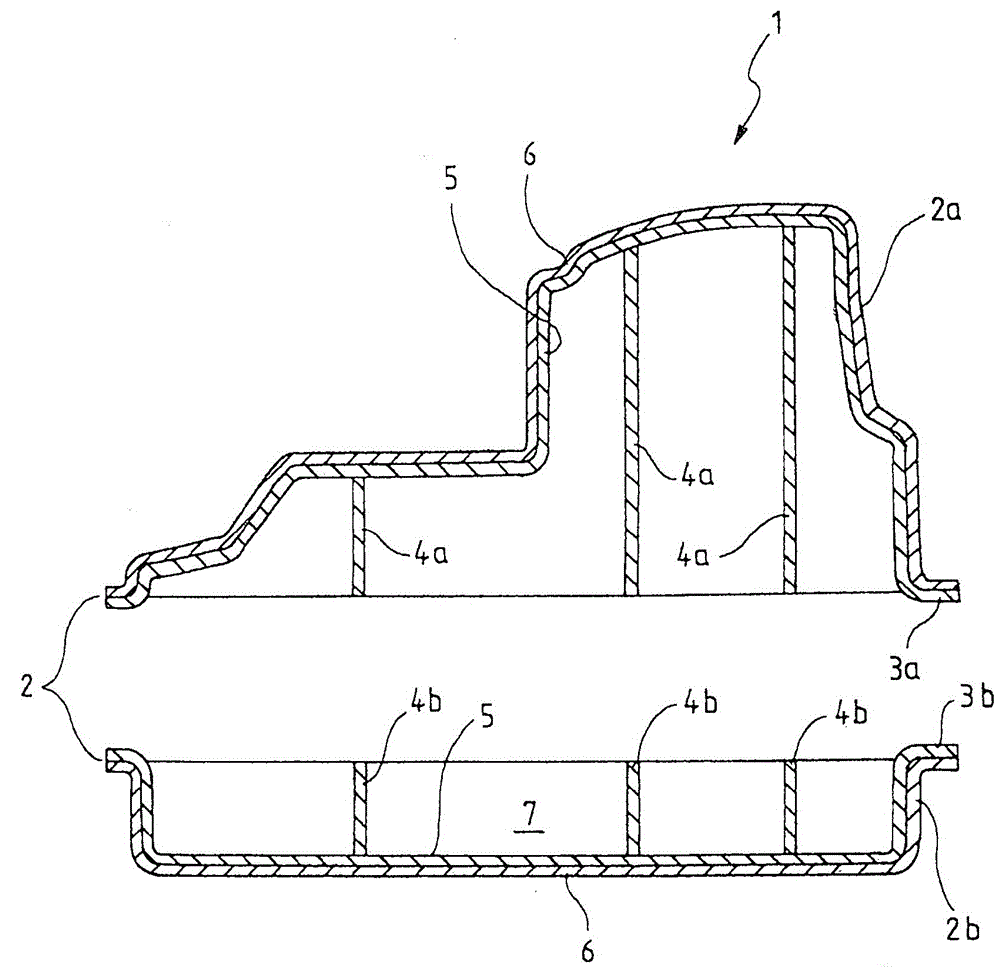

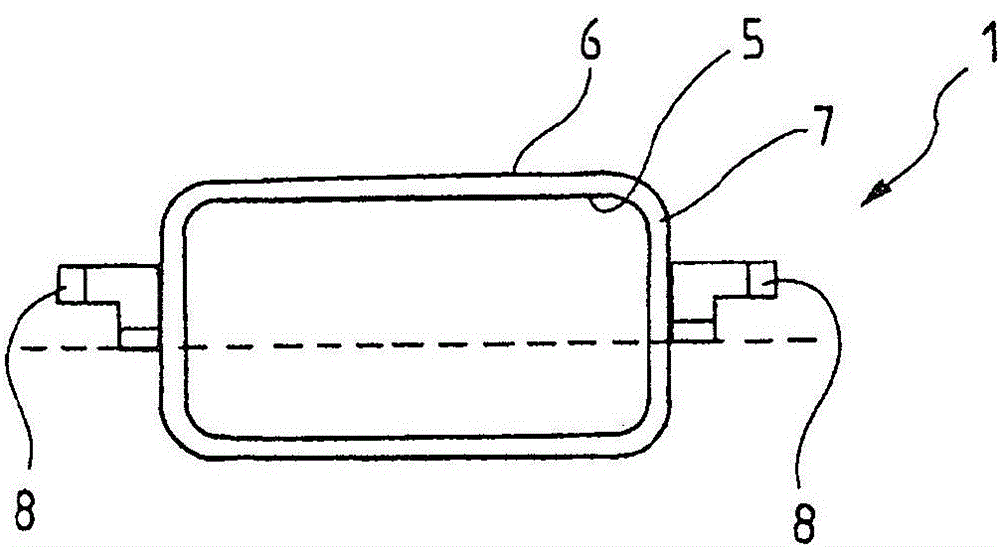

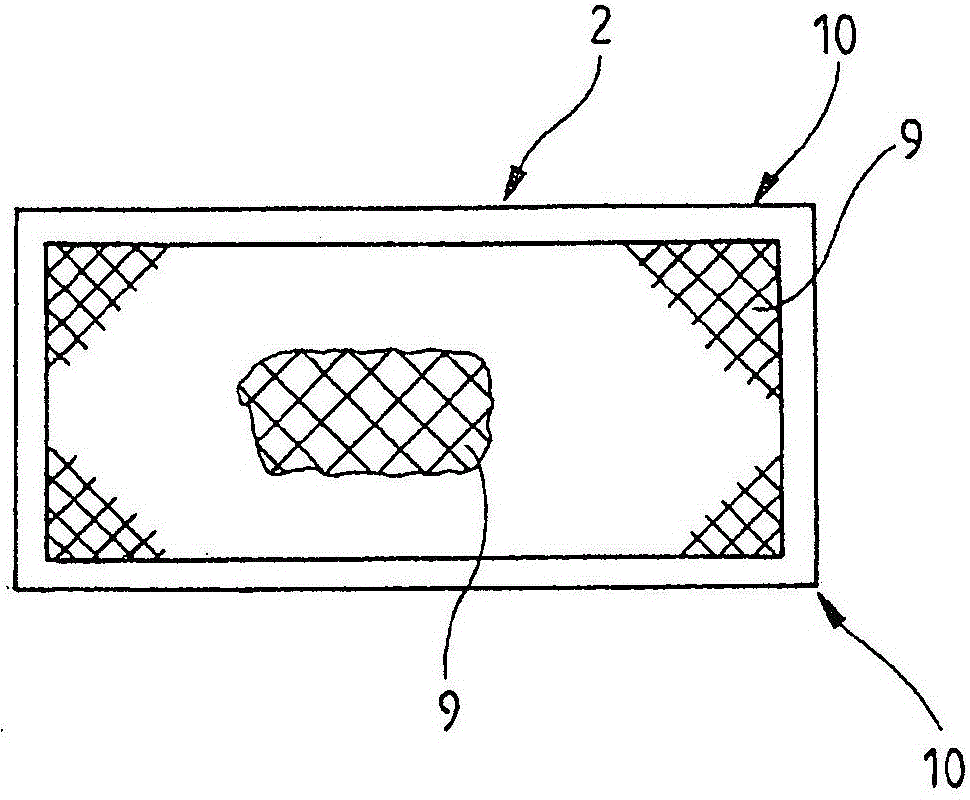

[0028] The working fluid container 1 according to the invention is basically assembled from two injection molded shells 2a, 2b, wherein the shell 2a forms the upper shell of the working fluid container 1 and the shell 2b forms the lower shell. The housings in each case form a peripherally surrounding flange 3a, 3b where the housings 2 are welded to each other to form a closed working fluid container. Each housing 2 has been obtained by co-injection molding, wherein in accordance with figure 1 In the exemplary embodiment shown, both the upper and lower housings have in each case a one-piece molded structure, for example in the form of a partition wall element 4a, 4b.

[0029] exist figure 1 In the exemplary embodiment of the invention shown in , the housing 2 is in each case formed in two layers, comprising an inner layer 5 and an outer layer 6 . These layers are made of different thermoplastic materials with different strengths and / or different molecular structures. The mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com