Production method for producing kintting complex fabric with high moist-conducting function

A manufacturing method and technology of composite fabrics, which are applied in the directions of knitting, weft knitting, textiles and papermaking, etc., can solve the problems of decreased moisture-conducting and quick-drying effect, long drying time, inability to wash with water, etc., and achieve good moisture-conducting and quick-drying effect. , The effect of short drying time and high washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

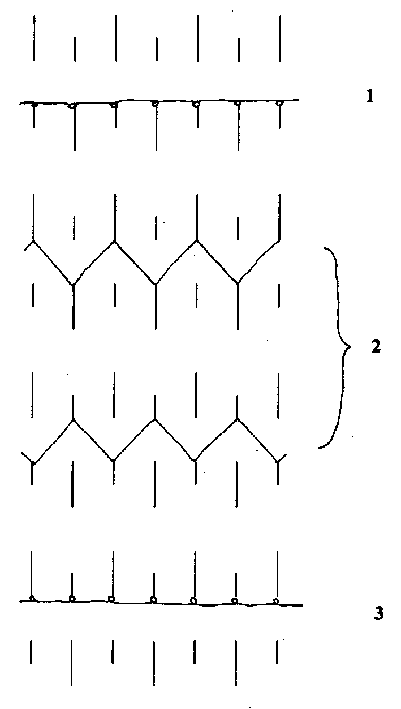

Image

Examples

Embodiment

[0028] (1) Use a Guoqiang brand 25ml burette to drop a drop of water on the inner layer of the fabric, and all the water in the inner layer of the polypropylene double-layer knitted fabric will be absorbed to the outer layer of the fabric, and it will take 30-60 seconds to make the inner layer of the fabric dry. The water in the fabric inner layer of the knitted composite fabric with high moisture-conducting function of the present invention is completely absorbed into the fabric outer layer, and it only takes 20-40 seconds to keep the fabric inner layer in a dry state. It can be seen that the drying time of the present invention is 33% shorter than that of the existing polypropylene double-layer knitted fabric.

[0029] (2) Due to the use of polyester fibers, polyester fibers have grafting properties, and grafted hydrophilic agents such as Haizhiwei are added to the fabric during dyeing and finishing. The washing fastness is very high, and the effect of the fabric is still ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com