Pressure-sensitive adhesive tape

A technology of pressure-sensitive adhesives and tapes, applied in the directions of adhesives, film/sheet-like adhesives, optics, etc., can solve the problems of increasing the total thickness of pressure-sensitive adhesive tapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

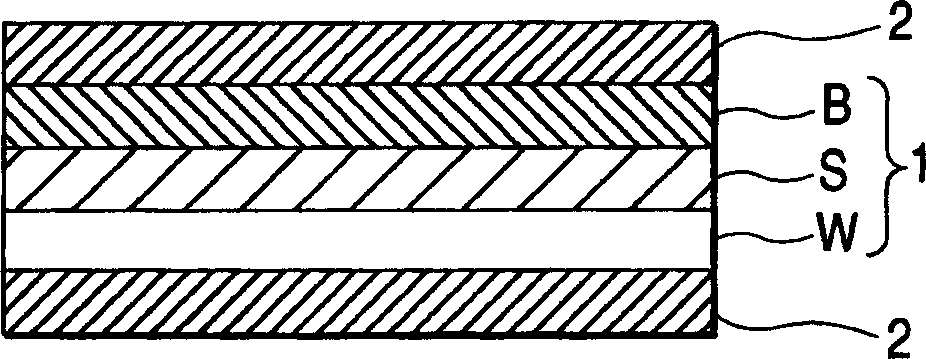

[0060] By printing on one side of a white base film (polyethylene terephthalate; chromaticity L: 92) with a thickness of 38 microns, three colored layers, the white layer (chromaticity L: 92), are formed in this order. ), a silver layer (chroma L: 75) and a black layer (chroma L: 25). This film was used as a substrate. The ink used for printing the colored layer was NB-500 manufactured by Dainichiseika Color & Chemicals Mfg. Co., Ltd. Each colored layer was formed with a thickness of 1 micron. A clear acrylic pressure sensitive adhesive was applied to each side of the substrate and dried to form a pressure sensitive adhesive layer having a thickness of 20 microns. A double-sided pressure-sensitive adhesive tape was thus obtained.

Embodiment 2

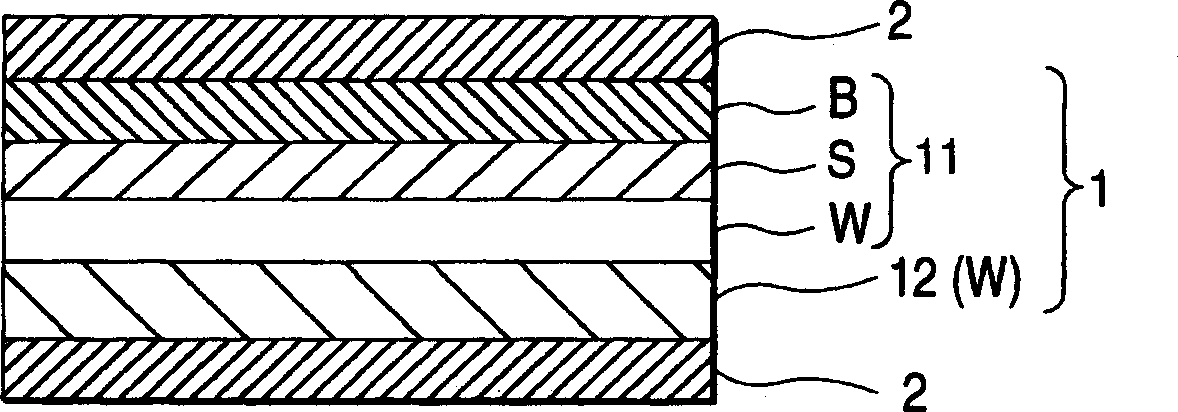

[0062] By printing on one side of a white base film (polyethylene terephthalate; chroma L: 92) with a thickness of 38 microns, three colored layers, namely silver layers (chroma L: 92) are formed in this order. ), black layer (chroma L: 25) and black layer (chroma L: 25). This film was used as a substrate. The ink used for printing the colored layer was NB-500 manufactured by Dainichiseika Color & Chemicals Mfg. Co., Ltd. Each colored layer was formed with a thickness of 1 micron. A clear acrylic pressure sensitive adhesive was applied to each side of the substrate and dried to form a pressure sensitive adhesive layer having a thickness of 20 microns. A double-sided pressure-sensitive adhesive tape was thus obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com