Zinc selenide nano crystal in situ growth method in silicon dioxide gel glass substrate

A technology of gel glass and silicon dioxide, which is applied in the field of new optical functional materials, can solve the problems of restricting the research and development of zinc selenide nanocrystalline glass materials, wide size distribution of functional nanoparticles, and high price, and achieve narrow size distribution, Small size, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

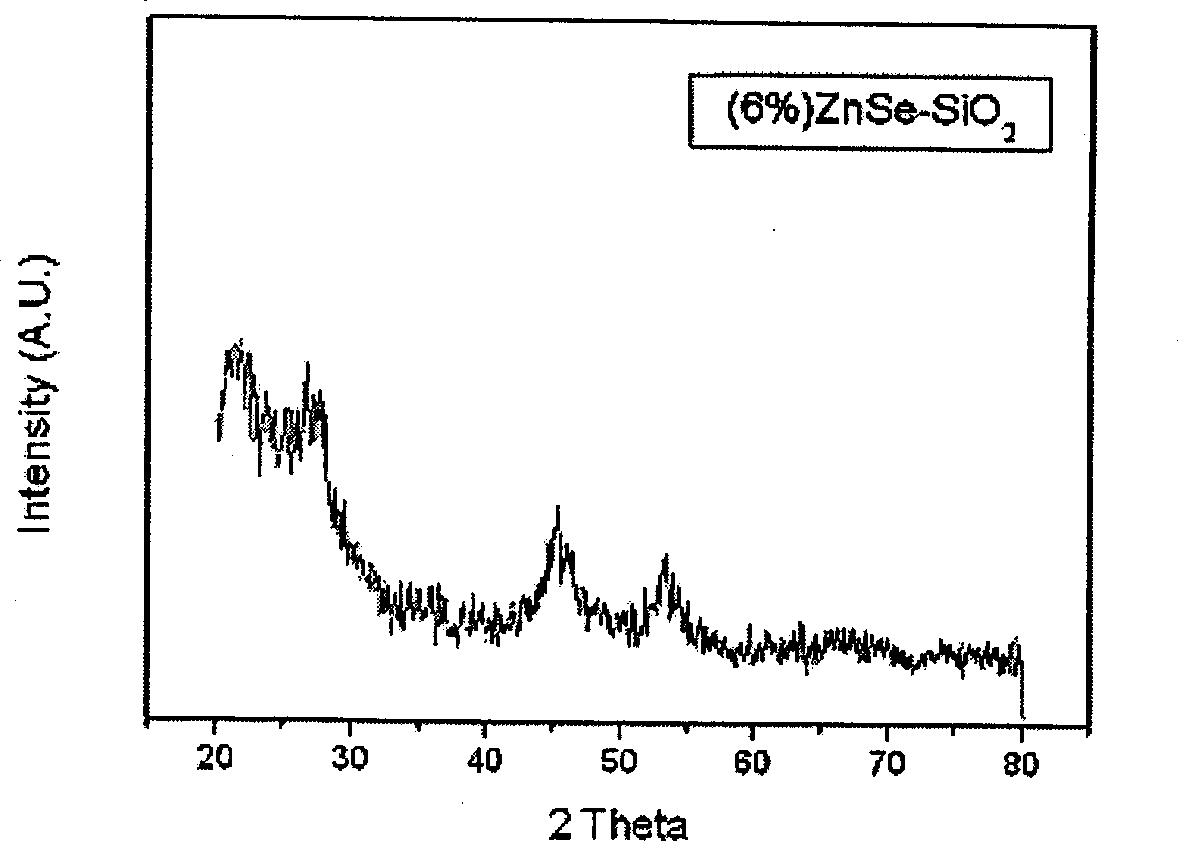

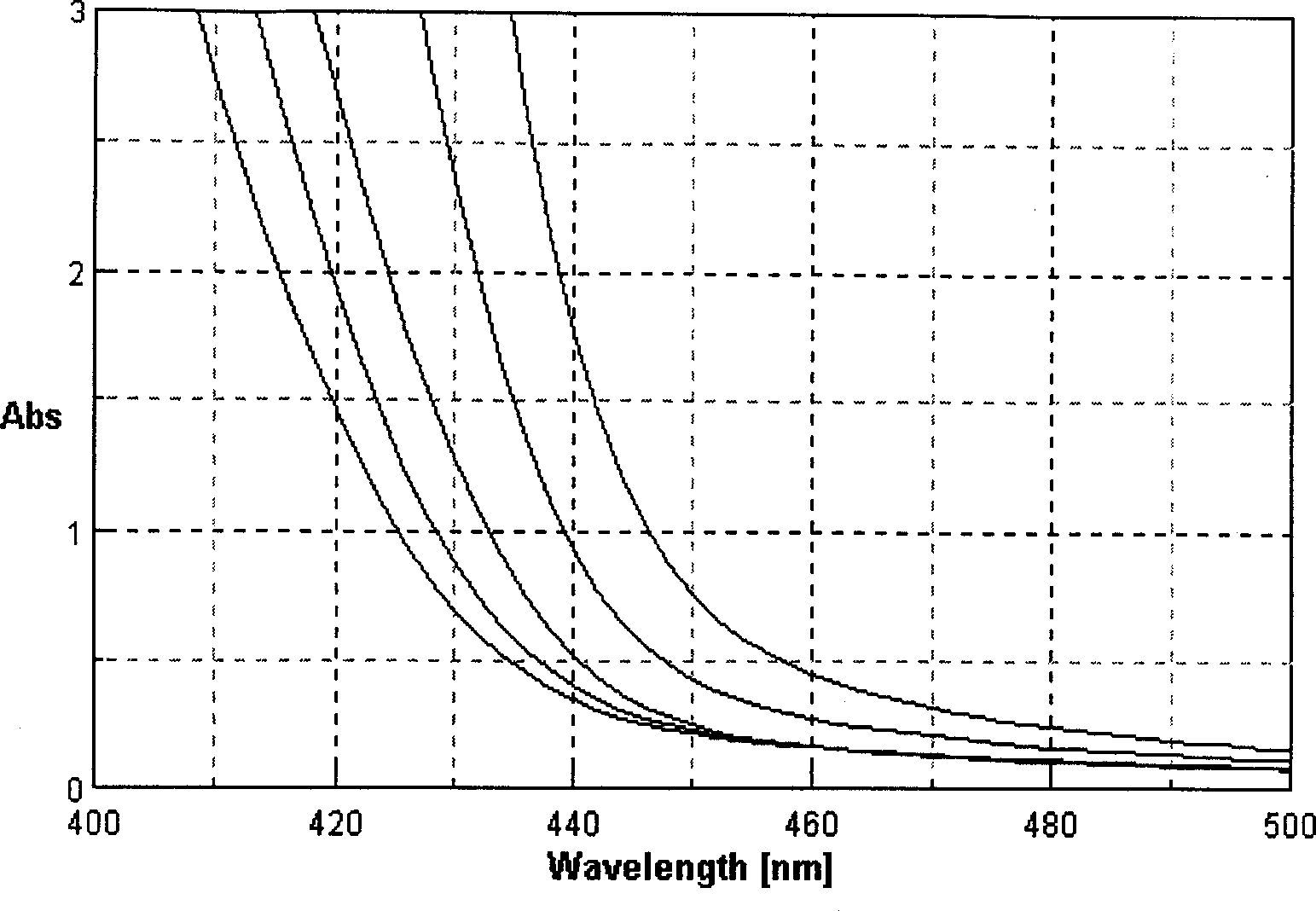

Image

Examples

Embodiment 1

[0027] The preparation method of said gel precursor comprises the following steps successively:

[0028] a. The initial raw materials for preparing gel glass are regular ethyl acetate, absolute ethanol, deionized water, and selenic acid. Their molar ratio is: 1:2-4:4-5:0.0025-0.005; absolute ethanol is used as a dispersant for normal acid ethyl ester, deionized water is used for hydrolysis reaction, and selenic acid is used as a catalyst for hydrolysis reaction.

[0029] B. The introduction of selenium source and zinc source adopts the form of zinc selenate: take zinc acetate and selenic acid in a molar ratio of 1:1, first dissolve zinc acetate in an appropriate amount of deionized water, and then add the weighed selenic acid , fully stirred, heated and evaporated to precipitate zinc selenate, and set aside.

[0030] c. First disperse regular acid ethyl ester in absolute ethanol, stir evenly; then add deionized water, and dropwise add selenic acid with a molar concentration o...

Embodiment 2

[0036] The preparation method of said gel precursor comprises the following steps successively:

[0037] a. The initial raw materials for preparing gel glass are regular ethyl acetate, absolute ethanol, deionized water, and hydrochloric acid. Their molar ratio is: 1:2-4:4-5:0.0025-0.005; absolute ethanol is used as a dispersant for normal acid ethyl ester, deionized water is used for hydrolysis reaction, and hydrochloric acid is used as a catalyst for hydrolysis reaction.

[0038] B, the introduction of selenium source and zinc source adopts the form of zinc selenate; According to molar ratio 1: 1, take by weighing zinc acetate and selenic acid, first zinc acetate is dissolved in appropriate amount of deionized water, then add the selenic acid that weighs , fully stirred, heated and evaporated to precipitate zinc selenate, and set aside.

[0039] c. Disperse TEOS in absolute ethanol and stir evenly; then add deionized water, and dropwise add hydrochloric acid with a molar con...

Embodiment 3

[0045] The preparation method of said gel precursor comprises the following steps successively:

[0046]a. The initial raw materials for preparing gel glass are regular ethyl acetate, absolute ethanol, deionized water, and nitric acid. Their molar ratio is: 1:2-4:4-5:0.0025-0.005; absolute ethanol is used as a dispersant for normal acid ethyl ester, deionized water is used for hydrolysis reaction, and nitric acid is used as a catalyst for hydrolysis reaction.

[0047] B, the introduction of selenium source and zinc source adopts the form of zinc selenate; Take by weighing zinc acetate and selenic acid in molar ratio 1: 1, zinc acetate is dissolved in appropriate amount of deionized water earlier, then add the selenic acid that weighs , fully stirred, heated and evaporated to precipitate zinc selenate, and set aside.

[0048] c. First disperse regular acid ethyl ester into absolute ethanol, stir evenly; then add deionized water, and dropwise add nitric acid with a molar concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com