Foamed shoe body formed by integral whole shaping method

A manufacturing method and shoe body technology, applied to footwear, footwear, shoe soles, etc., can solve the problems of low plastic deformation, high cost, monotonous appearance, etc., and achieve high product yield, cost saving, and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

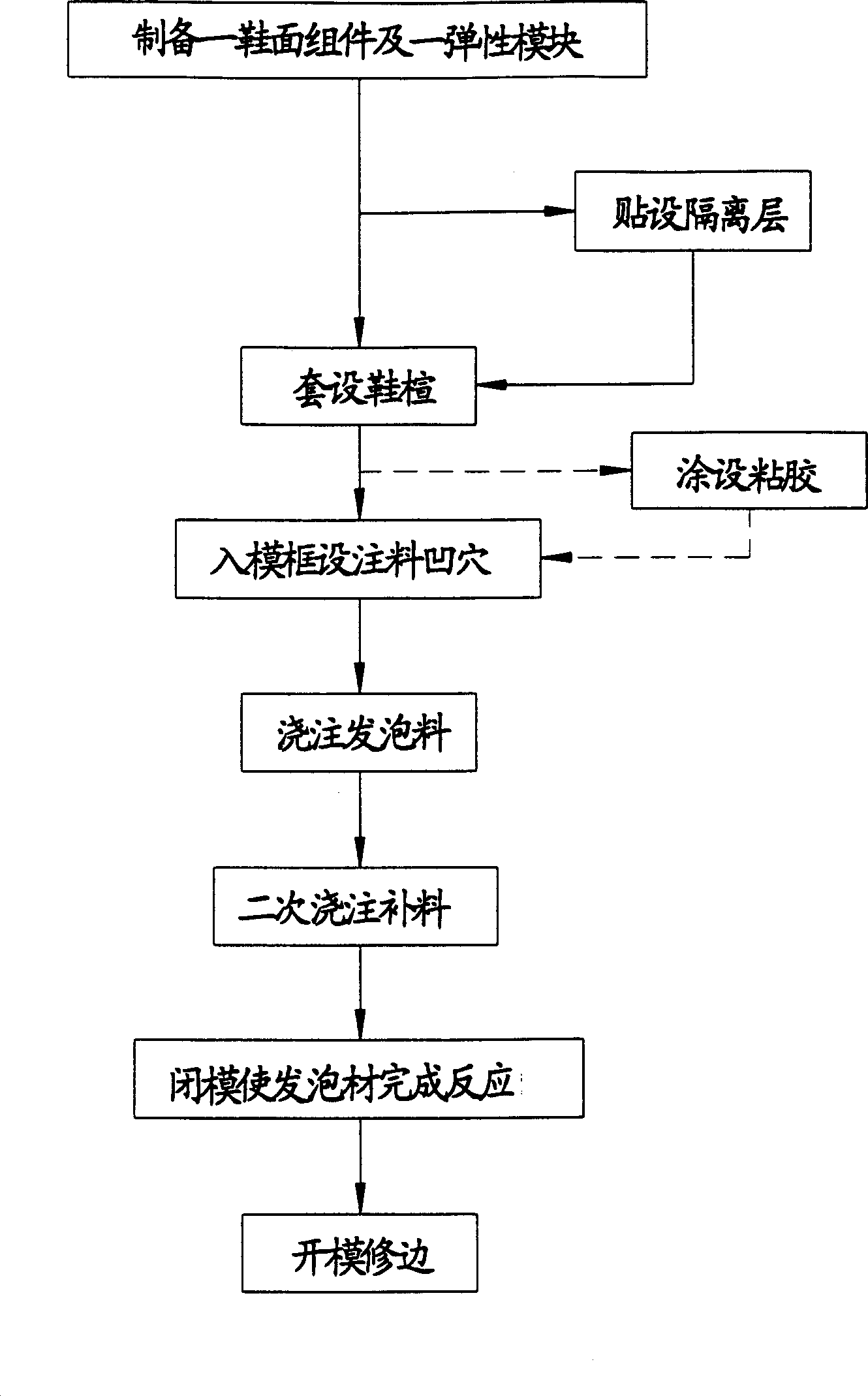

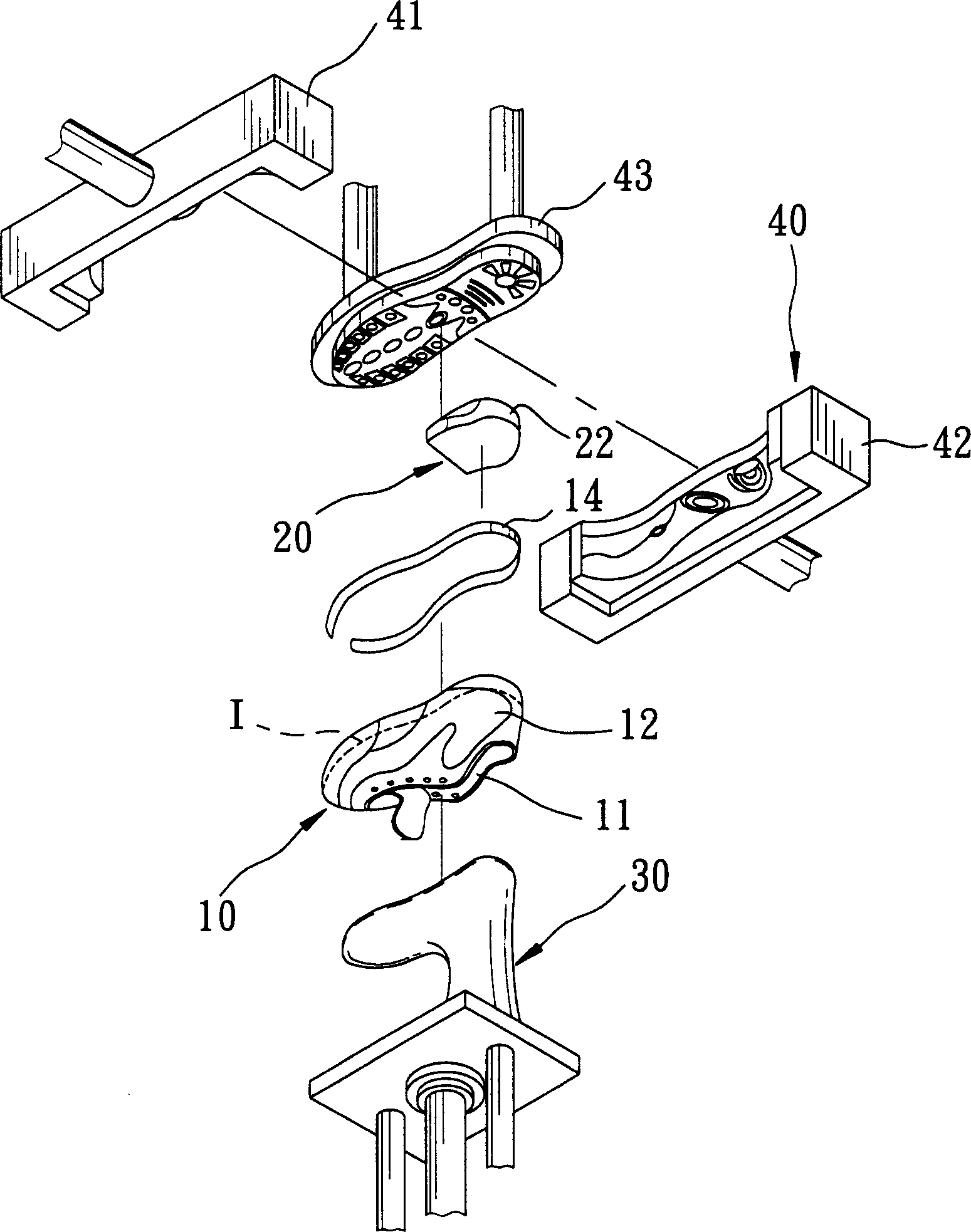

[0064] refer to Figure 2-5 As shown, the manufacturing method of the foamed shoe body of the present invention, a first preferred embodiment includes the following steps:

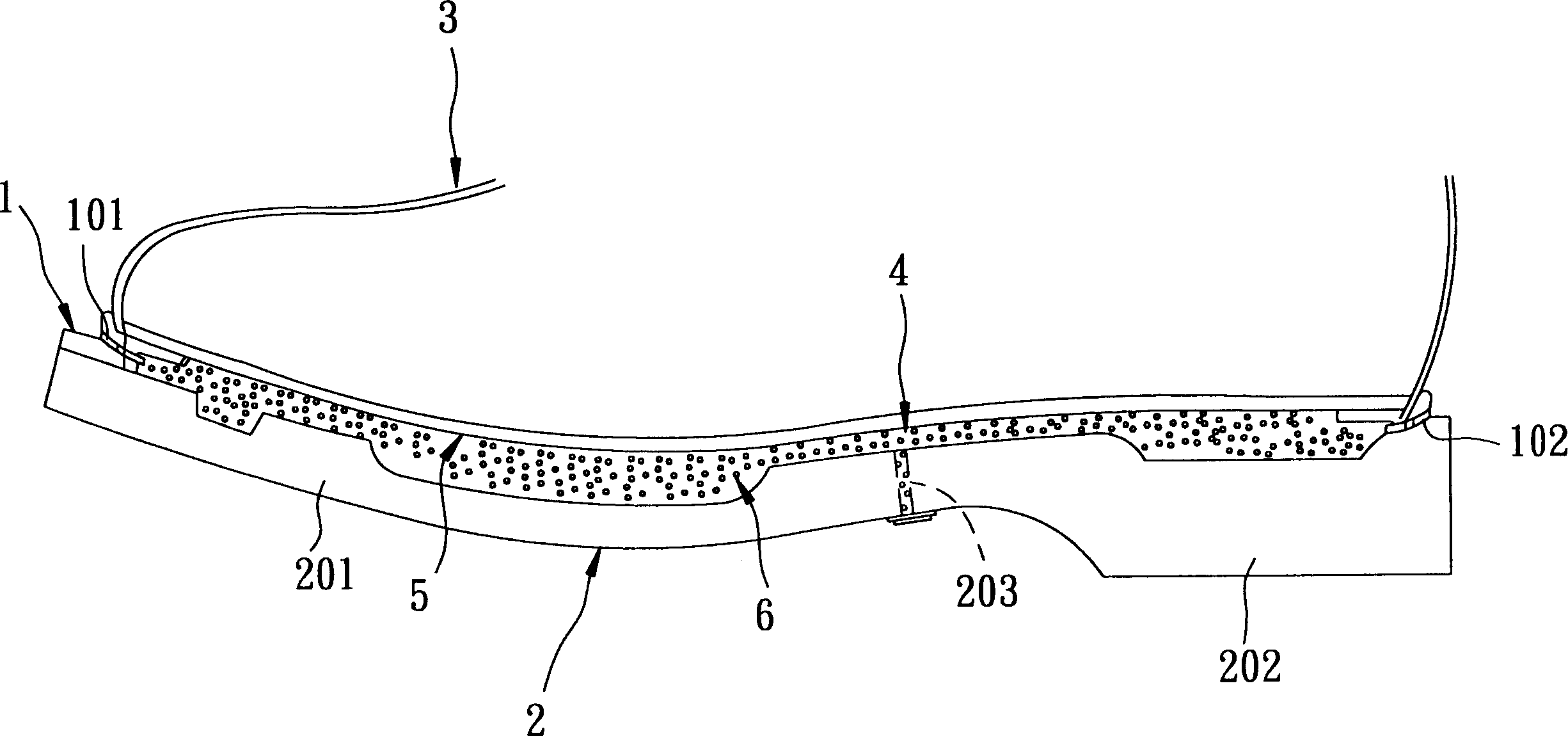

[0065] 1. Preparation of a shoe upper component 10 and an elastic module 20: the shoe upper component 10 is formed by combining more than one piece of elastic and stretchable material in a sewing manner, and has a top opening 11 at the top edge, an outer surface around the outer circumference 12, and a sole pad 13 located at the bottom of the upper assembly 10 and connected to the outer surface 12. In this embodiment, the elastic module 20 is made into an independent block corresponding to the shape of the rear heel of the human body, and the elastic The module 20 has a bottom surface 21 , an outer surface 22 surrounding the bottom surface 21 , and a material injection area 23 recessed on the bottom surface 21 .

[0066] 2. Paste (spray) the overflow material isolation layer: an isolation layer 14, 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com