Multiple die industrial process control transmitter

A transmitter and chip technology, applied in program control, digital control, computer control, etc., can solve problems such as power consumption, and achieve the effect of improving range, reducing operating power, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

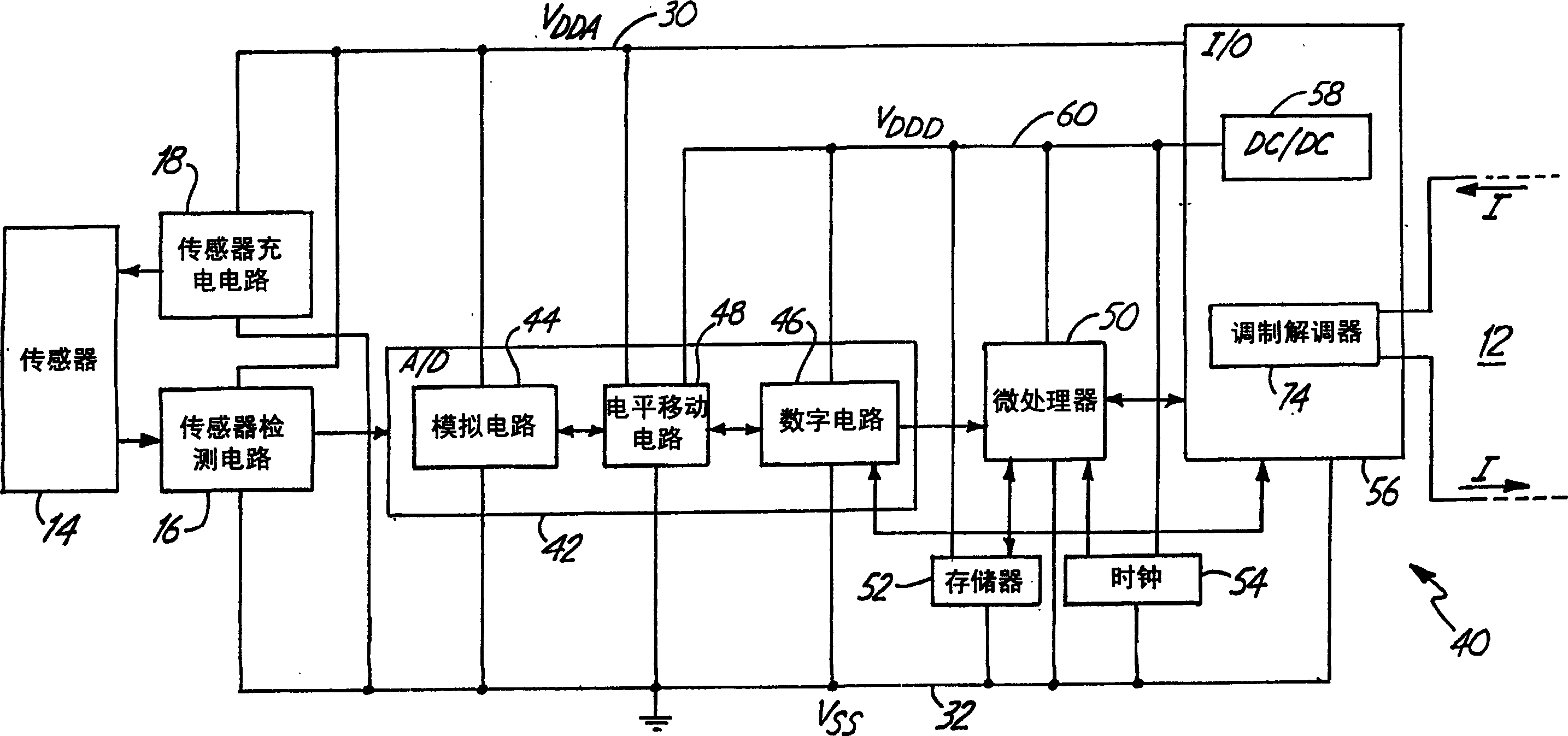

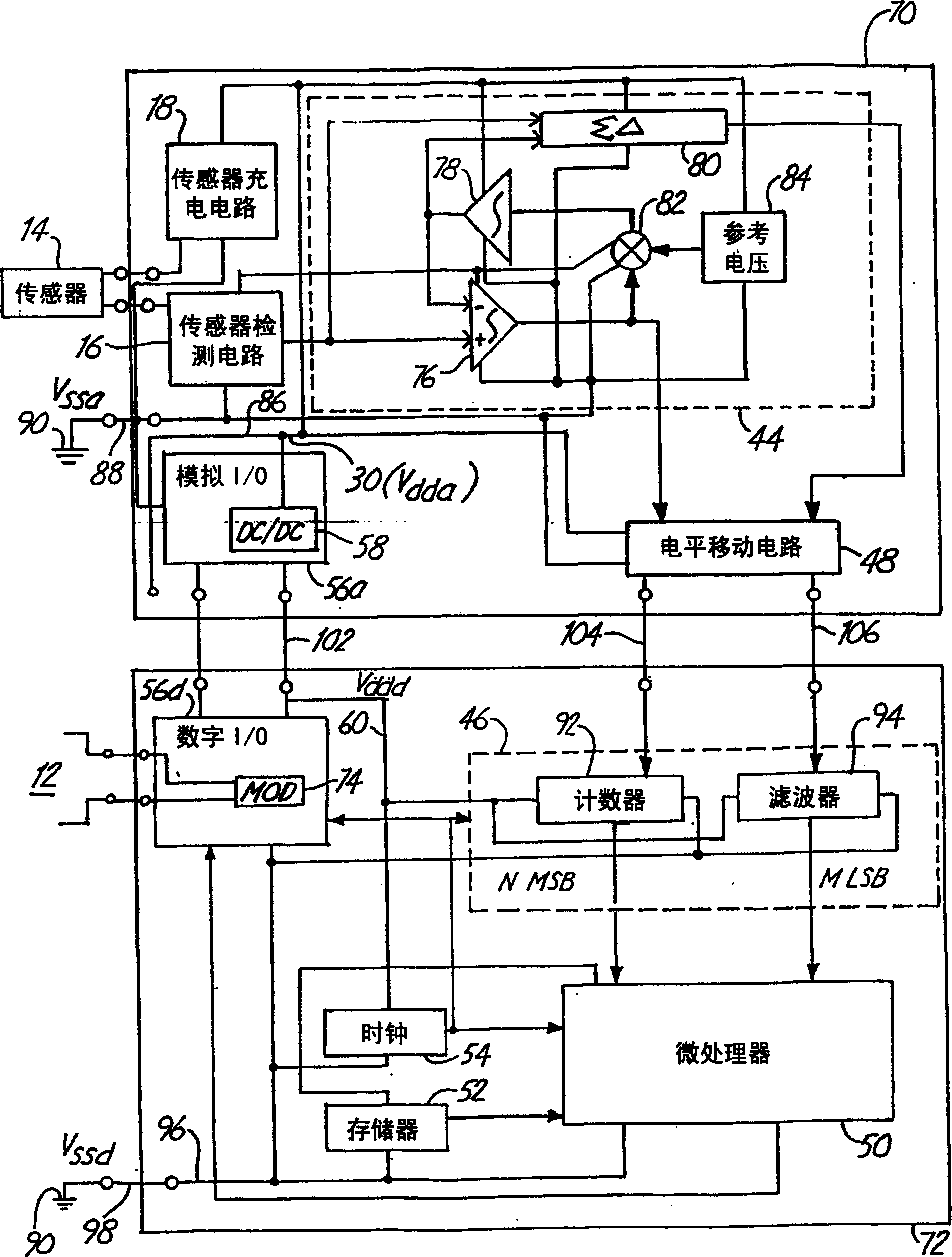

[0021] The "range," or the ratio of maximum to minimum span, of an industrial process control transmitter is limited by the transmitter's resolution, which in turn is limited by the available power. It is desirable to be able to increase the amplitude variation range to reduce the manufacturing costs associated with the transmitter. The present invention achieves increased resolution by separating some of the transmitter's analog circuits from some of the digital circuits, and reallocating the power saved from the digital circuits to the analog circuits. With greater power on the analog circuitry, the resolution is improved, thereby increasing the amplitude variation range and reducing manufacturing costs.

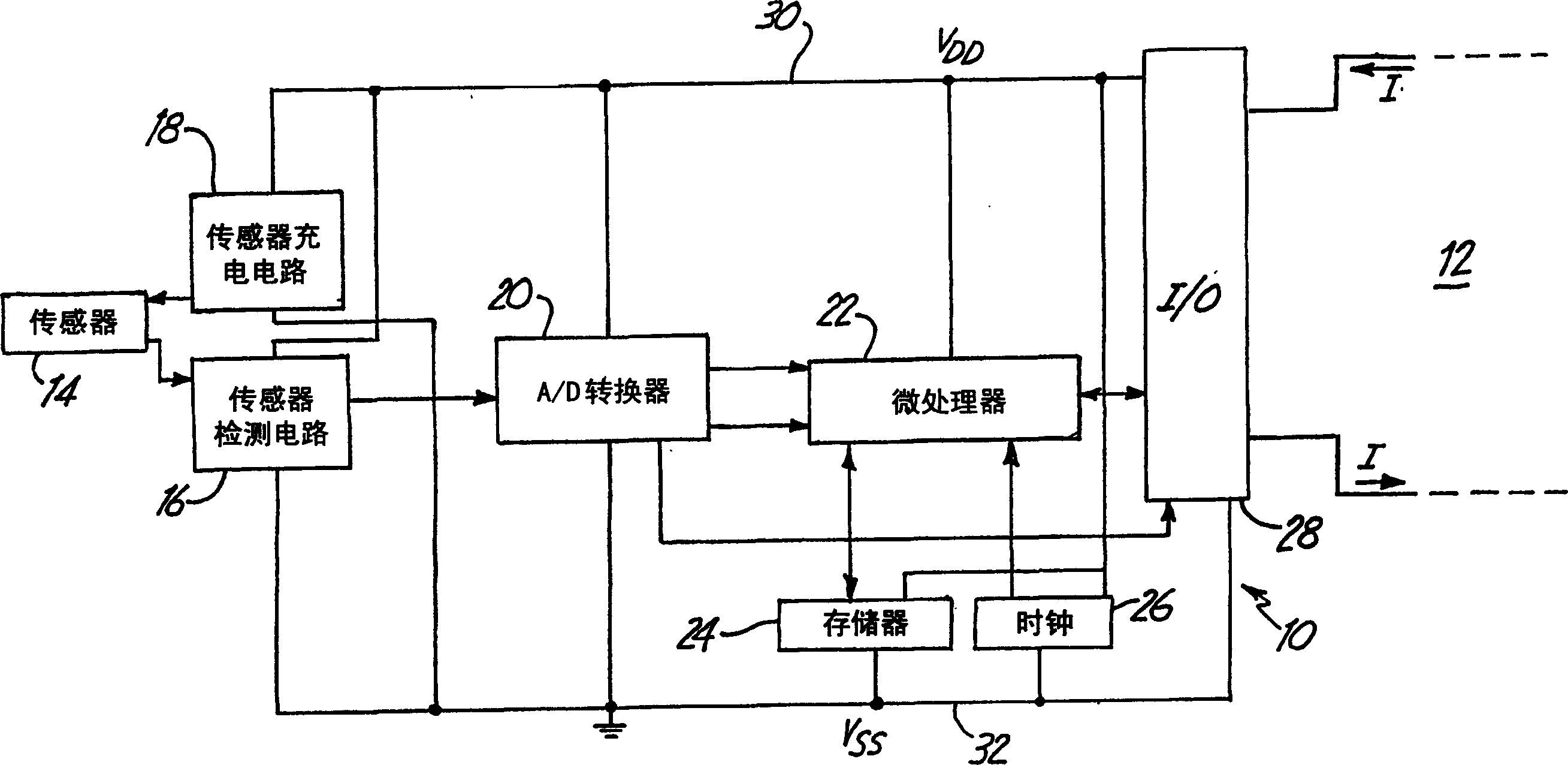

[0022] figure 1 is a block diagram of a prior art two-wire industrial process control transmitter 10 . Transmitter 10 is coupled to a two-wire processing control loop 12 that carries current I. For example, loop 12 may be a 4-20 mA process control loop capable of operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com