Wood base board for container of domestic material mode from leftover and its manufacturing method

A manufacturing method and container technology, applied to chemical instruments and methods, packaging, wrapping paper, etc., can solve the problem of undiscovered wooden floor for containers, and achieve the effects of alleviating the shortage of resources, increasing the rate of material yield, and saving wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

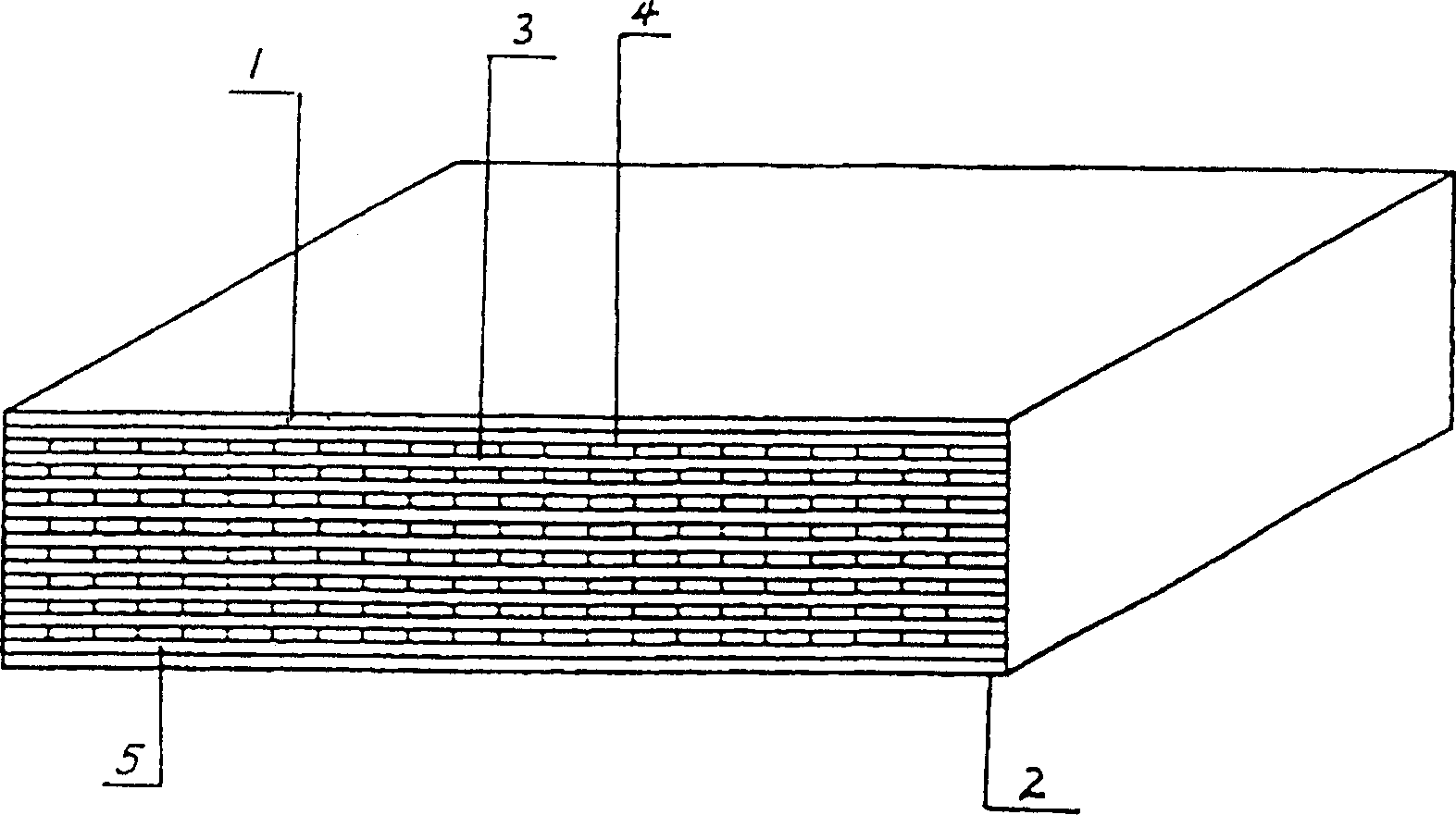

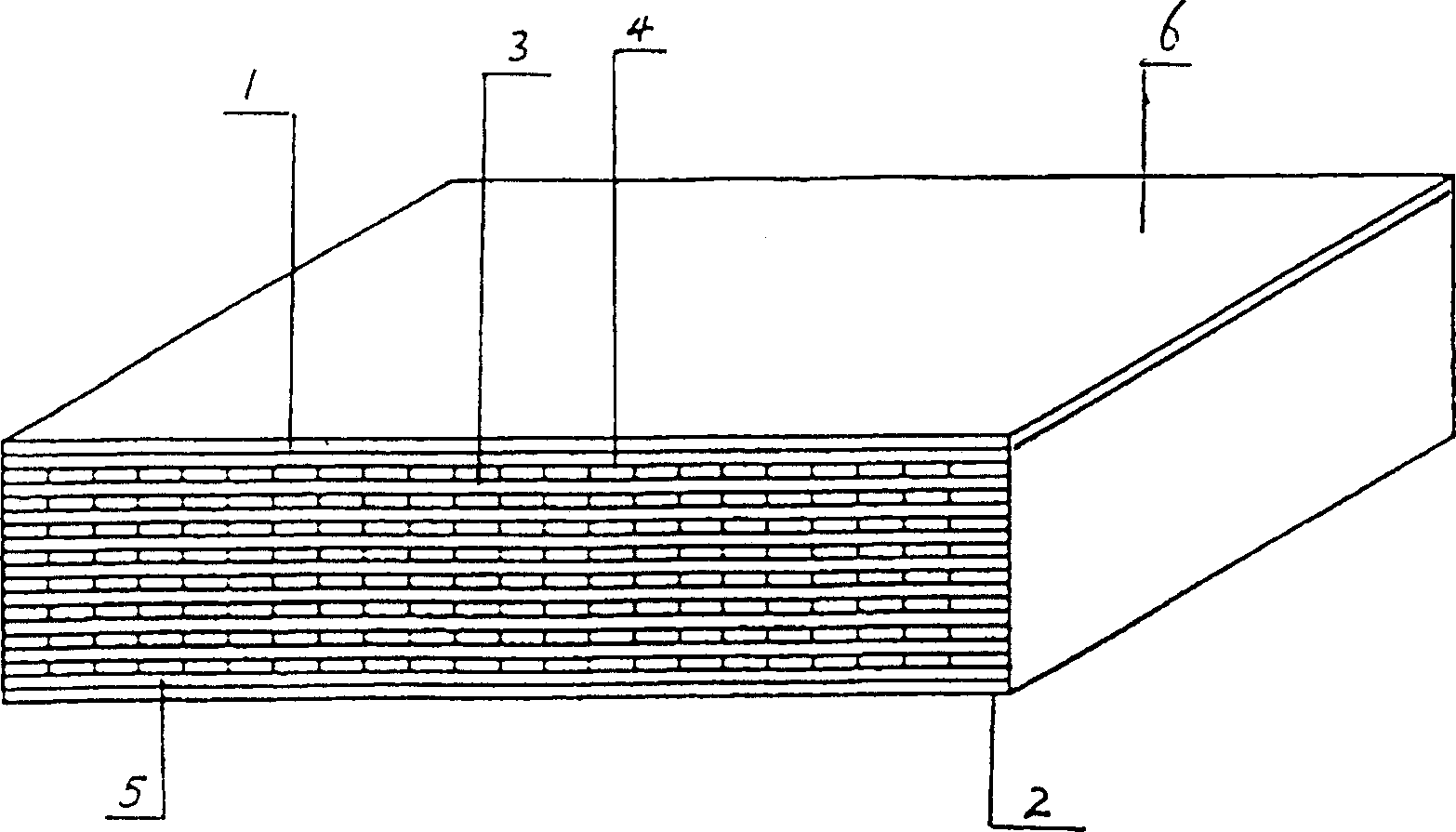

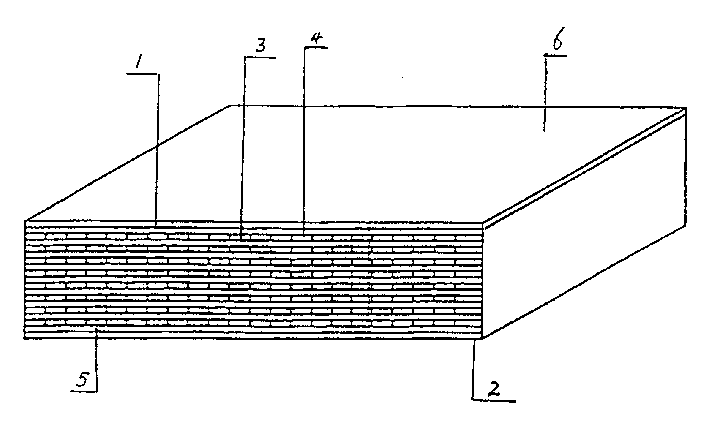

Image

Examples

example 1

[0038] The present invention adopts the patented technology of "manufacturing method of domestic wood container wooden floor" to heat-press the edges, corners, and scraps produced in the production process into 11 layers of vertical and horizontal staggered blanks to form a core plate, and the thickness of the core plate after sanding 15mm, pasted with 4 layers of frigid hardwood veneer, with a thickness of 1.65 (or cloned wood veneer), after the second overlay molding, its physical and mechanical properties are:

[0039] Specific gravity: 0.77 g / m 2

[0040] Moisture content: 8%

[0041] Static bending strength (longitudinal): 103.9MPa

[0042] Static bending strength (transverse direction): 60.8MPa

[0043] Elastic modulus (longitudinal): 1172Mpa

[0044] Elastic modulus (horizontal): 4822Mpa

example 2

[0046] The invention adopts quick-grown poplar (Italian poplar) rotary-cut veneer boards in Jiangsu, Anhui, and Shandong regions with a thickness of 1.8-2.0 mm, and is hot-pressed into a core board through 11 layers of vertical and horizontal cross-cut billets. After sanding, the thickness is 12mm, and the upper and lower layers are covered with cold zone hardwood veneer for the second time, with a thickness of 1.65 (or cloned wood veneer). The physical and mechanical properties are as follows:

[0047] Specific gravity: 0.78 g / m 2

[0048] Moisture content: 9.2%

[0049] Static bending strength (longitudinal): 95.0MPa

[0050] Static bending strength (transverse direction): 57.1MPa

[0051] Elastic modulus (longitudinal): 12179MPa

[0052] Elastic modulus (horizontal): 5062Mpa

example 3

[0054] The present invention adopts the production process of Example 2, but the thickness of the quick poplar veneer used for the core board is 1.8-2.0 mm, and a total of 13 layers of vertical and horizontal cross blanks are hot-pressed into the core board. After sanding, the thickness is 15mm, and then up and down, each layer is covered with 4 layers of cold zone hardwood veneer, the thickness is 1.65 (or cloned wood veneer), and the physical and mechanical properties are as follows:

[0055] Specific gravity: 0.70 g / m 2

[0056] Moisture content: 8.5%

[0057] Static bending strength (longitudinal): 87.78MPa

[0058] Static Bending Strength (Transverse): 42.79MPa

[0059] Modulus of elasticity (longitudinal): 12436Mpa

[0060] Elastic modulus (horizontal direction): 4319Mpa

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com