Railway signal cable and method for manufacturing the same

A railway signal and manufacturing method technology, applied in the direction of cable/conductor manufacturing, communication cables, insulated cables, etc., can solve the problems of dielectric constant reduction, line transmission attenuation constant reduction, and affecting signal transmission quality, etc., to save construction costs, The effect of protecting product quality and reasonable workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

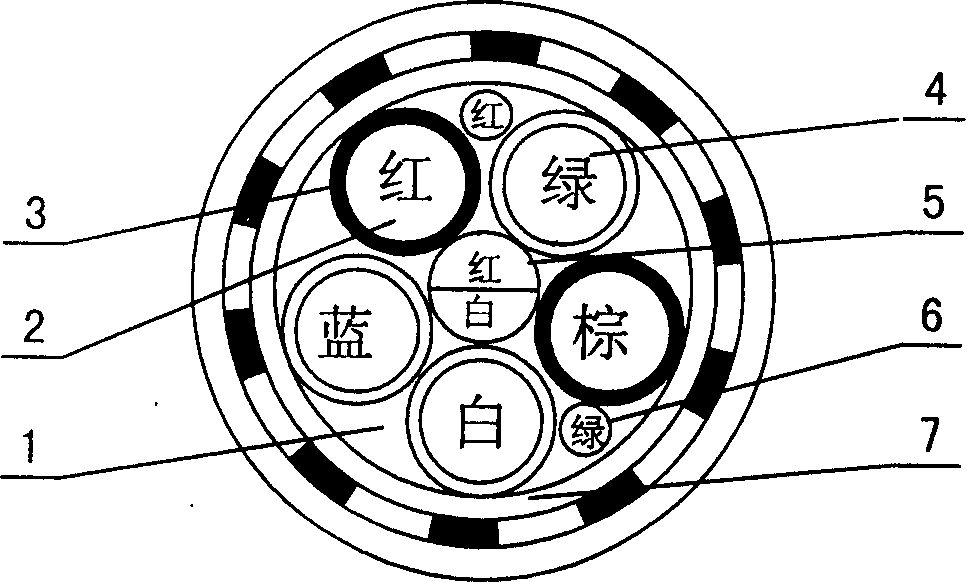

Embodiment 1

[0026] First, a copper conductor with a circular cross-section and a diameter of 1.0mm is drawn by a wire drawing machine; and the conductor is fed into an insulating layer extruder with a three-layer co-extrusion function, and the extruder heats and melts the three layers of insulating materials And form a three-layer insulating layer of solid inner skin, foam and solid outer skin outside the conductor. In the process of heating and extrusion, injecting nitrogen into the foam layer raw material means adopting the general physical foaming method, or adding azo to the foam layer raw material. Diisobutyronitrile (N-type foaming agent), azodicarbonyl ester (AC-type foaming agent) and other foaming agents are extruded and foamed, that is, the chemical foaming method is used; the insulating layer material is made of polyethylene or polyester. Polyolefin materials such as propylene; add color masterbatches of various colors to the polyolefin material of the solid skin layer as needed...

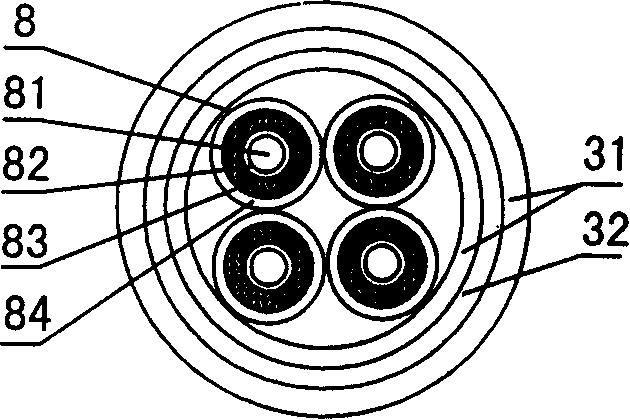

Embodiment 2

[0028] The copper wire is drawn into a copper conductor with a diameter of 1.13mm and a circular section, and the copper conductor is sent to three insulation layer extruders in sequence to complete the extrusion of the solid inner skin layer, the extrusion of the middle foam layer and the solid Extrusion of the outer skin layer, adding a chemical foaming agent to the raw material of the middle extruder to form the middle foam layer, and then wind-cooling and water-cooling the insulated core wires into a coil, twisting the coiled insulated core wires into a star-shaped quad Wire group and wire pair group; cover the pre-prepared shielding tape with the shielding tape on the four-wire group of the specified color, and wrap the other four-wire groups without shielding layer with wrapping tape and form a coil, and then shield the four-wire group, The four-wire group, pair-wire group, and core wires are twisted into cables according to the design requirements, and the following proc...

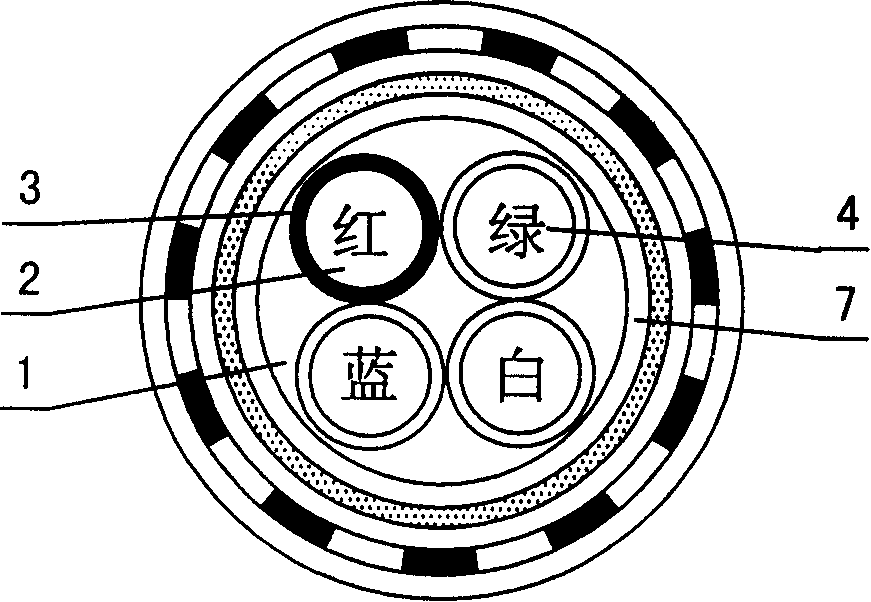

Embodiment 3

[0030] After being cabled according to embodiment 1, complete following operation successively again, the plastic insulation layer integrated sheath, steel tape armoring, outer sheath are installed additional.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com