Method for synthesizing molecular sieve film using vacuum crystal method

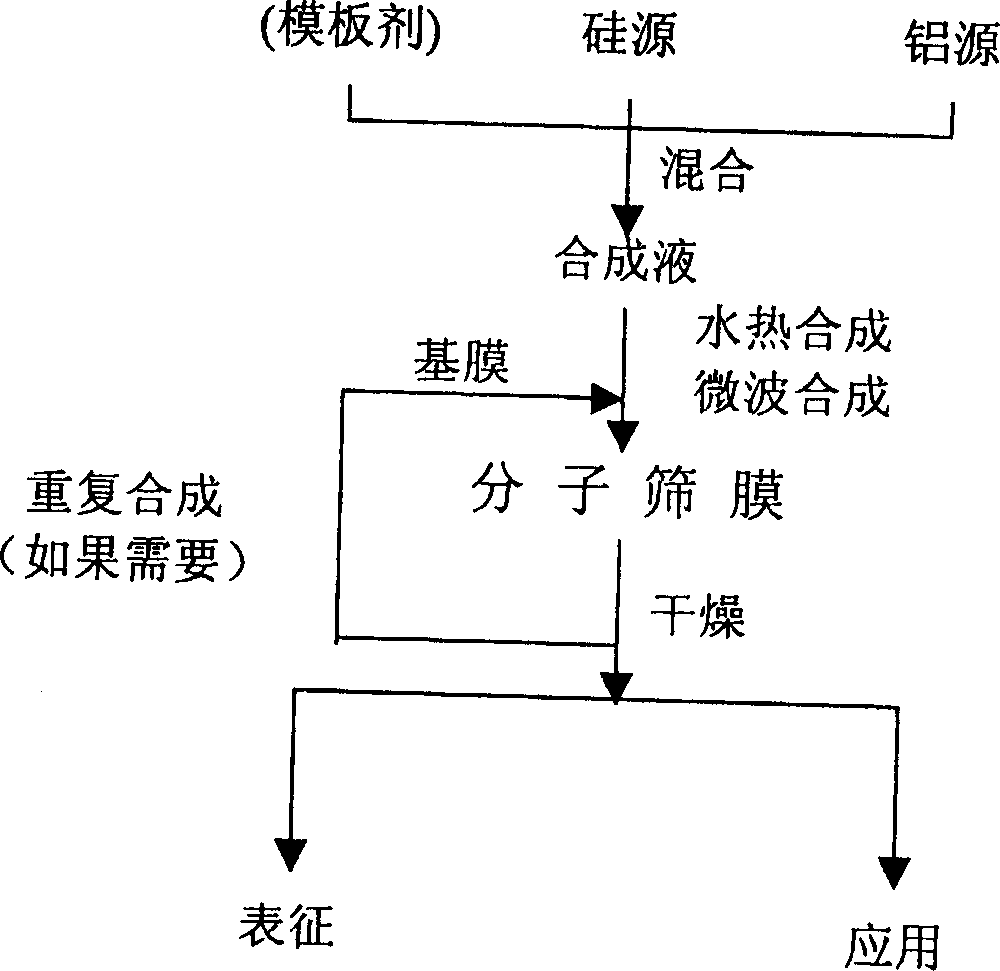

A technology of molecular sieve and crystal coating, which is applied in the field of synthesis of molecular sieve membranes, can solve the problems of being unsuitable for industrial amplification, unsuitable for industrial amplification, and difficult to control, and achieves high industrial application value, suitable for industrial amplification, and saving time for coating crystals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1 Preparation of seeded base film

[0027] Weigh 1.0 g of type A molecular sieve seed crystals, add 300 ml of distilled water, stir and fully oscillate and disperse in ultrasonic waves, and then fully oscillate and disperse in ultrasonic waves to form a uniform molecular sieve seed crystal suspension 1. The pressure difference between the inner and outer sides of the base film 2 is adjusted to 0.0050MPa by the water pump 3, and the tubular α-Al 2 o 3 The base film was vacuum dip-coated in the prepared molecular sieve seed crystal suspension for 120s and then taken out. After drying, dry and solidify at a certain temperature to obtain a seeded base film.

[0028] Synthesis of Step 2 Type A Zeolite Membrane

[0029] Weigh 156 grams of sodium hydroxide and dissolve in 300 milliliters of distilled water, add 2.1 grams of aluminum foil after clarification, stir to form an aluminum solution; measure 43.5 milliliters of silica sol (SiO 2 27wt%, ρ=1.16g / l) into 390 ml...

Embodiment

[0058] Example Seeded base film Film thickness Total flux Separation coefficient

[0059] Mass (μm) (Kg / m 2 h) (α) (water / isopropanol)

[0060] 1 Uniform and continuous 9 1.72 Above 10000

[0061] 4 evenly continuous 5 / /

[0062] 3 Uniform and continuous 10 1.47 Above 10000

[0063] 6 Uniform and continuous 14 1.29 Above 10000

[0064] 5 evenly continuous 7 / /

[0065] 7 evenly continuous 4 / /

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com