Method for making scrapping-resistant read/write surface for read/write type disc

A manufacturing method and technology of optical discs, which are applied in the manufacture of optical record carriers, optical recording carriers, etc., can solve the problems of increased production costs of optical discs, errors in writing data on optical discs, cumbersome processing procedures, etc., and achieve flatness, The effect of ensuring production quality and correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

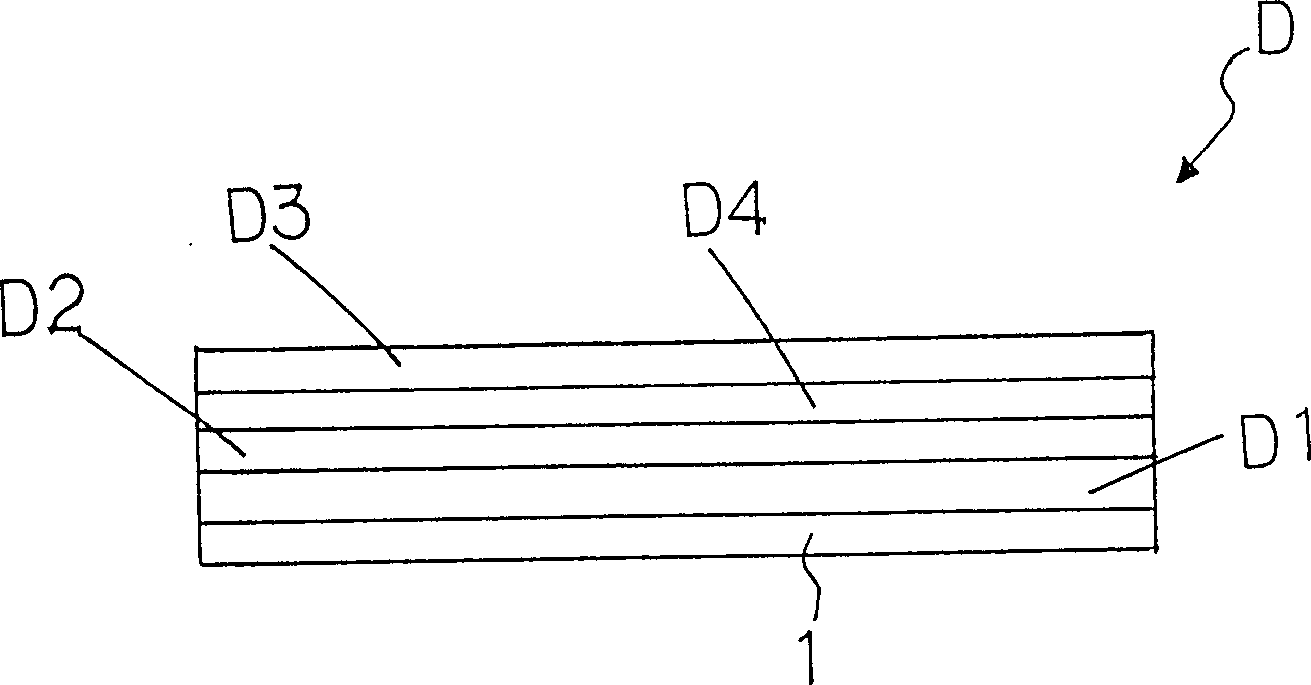

Embodiment 1

[0021] In the overall injection, it contains 60% of acrylate resin, 32% of TMPA and its EO.PO modified monomer, 5% of Irgacure-184 sensitizer, and 3% of wax to form a 40-50cps / 25° Viscosity state, under the working condition of the surface temperature of the optical disc at 35°C, apply the injection agent to the surface layer of the data reading and writing surface of the optical disc by means of centrifugal coating, and after the injection agent is coated, it takes 5 seconds to match The injection is irradiated with ultraviolet rays, so that the ingredients in the injection are converted into a light-transmitting film with a film thickness of 0.01±0.002mm with a hardness between 2H-7H, so that the light-transmitting film forms an optical disc The anti-scratch surface of the disc, in order to form an effective anti-scratch effect on the data reading and writing surface of the optical disc, and keep the data reading and writing surface flat, so as to increase the service life of...

Embodiment 2

[0023] The overall injection contains 60% acrylate resin, 24.5% monomer, 12.5% Irgacure-184 sensitizer, and 3% wax to form a viscosity state of 40-50cps / 25°. Under the working condition of 47°C, the injection agent is applied to the surface layer of the data reading and writing surface of the optical disc by means of centrifugal coating, and after the injection agent is coated, the injection agent is irradiated with ultraviolet light for 2.5 seconds.

Embodiment 3

[0025] In the overall injection, it contains 60% acrylate resin, 17% TMPA and its EO.PO modified monomer, 20% Irgacure-184 sensitizer, and 3% silane at 40-50cps / 25° In the viscosity state of the optical disc, under the working condition of the surface temperature of the optical disc at 60°C, apply the injection agent to the surface layer of the data reading and writing surface of the optical disc by means of centrifugal coating, and after the injection agent is coated, within 1 second The injection is irradiated with ultraviolet rays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com