Drawing bore method for pile shoe

A pile shoe and pile feeding technology is applied in the construction field of concrete pipe piles entering the foundation, which can solve the problems of limited depth of guide holes, influence of construction speed, and difficulty in pulling pipes, etc., and achieves the effect of simple construction method and simple construction equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

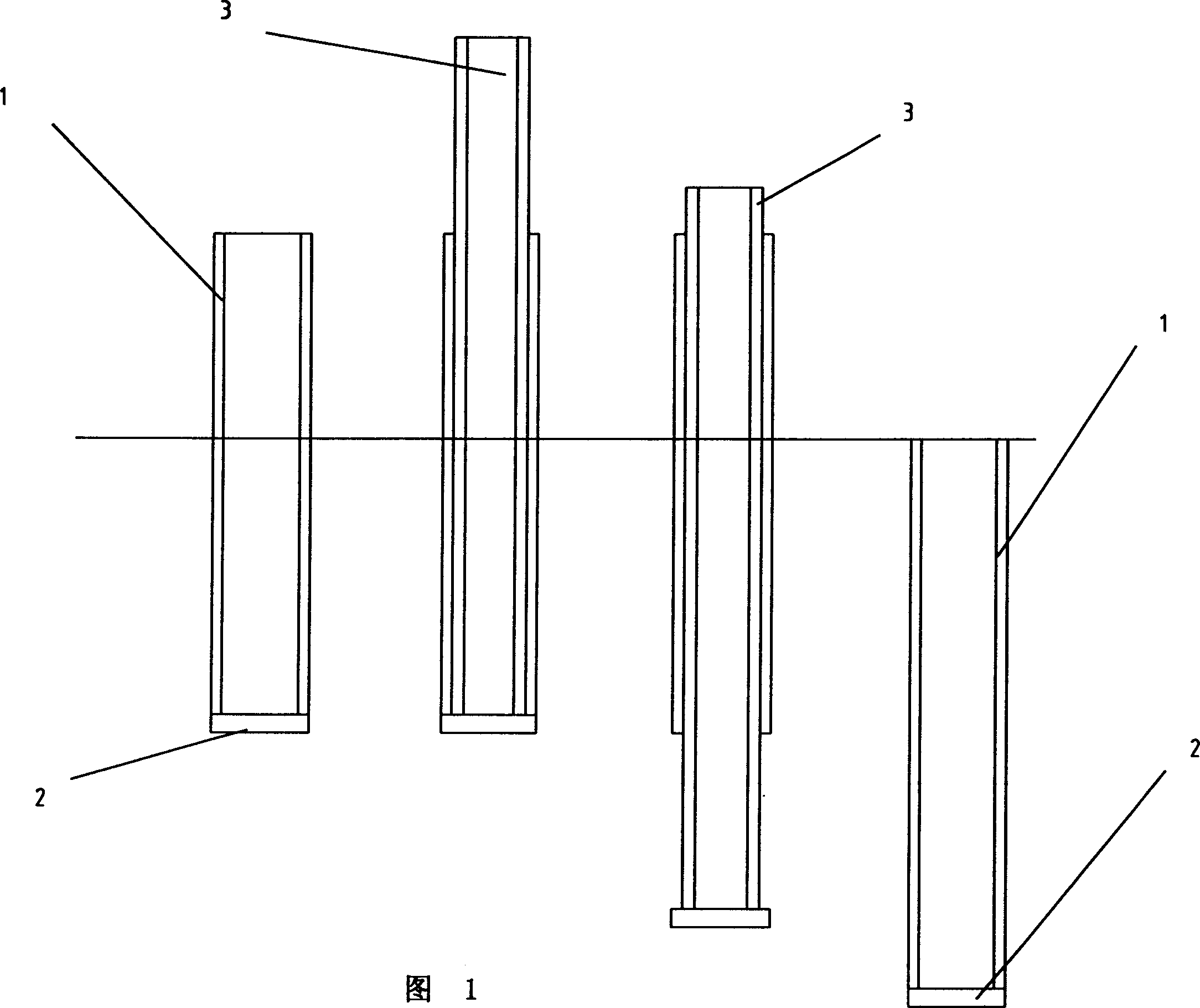

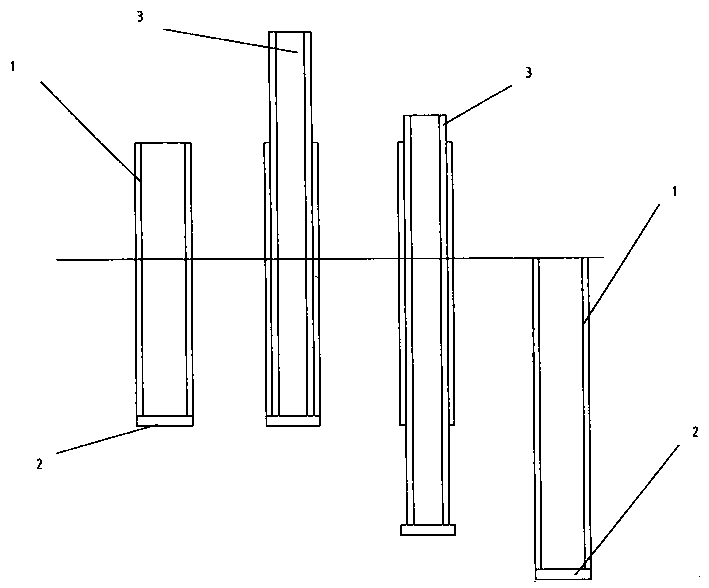

[0015] With reference to accompanying drawing, a kind of spud can lead hole method may further comprise the steps:

[0016] 1) Install a closed pile shoe 2 on the pile end of the concrete pipe pile 1;

[0017] 2) After positioning the pile 1, drive it into the foundation, and stop sending the pile before the pile sending force will reach the ultimate strength of the pile body;

[0018] 3) Put a steel pipe mandrel 3 of corresponding diameter into the cavity of the pipe pile;

[0019] 4) Use the static pressure mandrel 3 of the pile driver to send the pile shoe 2 to the set depth;

[0020] 5) Take out the mandrel and continue to send the pile to the design elevation to complete the pile foundation construction.

Embodiment 2

[0022] The difference from embodiment 1 is that in step 4, hammering the mandrel 3 is used to make the spud can 2 reach the set depth instead of using the static pressure of the pile driver.

Embodiment 3

[0024] Different from Embodiments 1 and 2, in this embodiment, after the spud can penetrates the hard layer, the pile body is sent to a deeper design depth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com