Integrated apparatus for ultrafine magnetic grain catalytic reaction and continuous segregation in liquid

A catalytic reaction and magnetic particle technology, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of high equipment cost and weak magnetic field strength, and achieve the effect of small fluid flow resistance and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

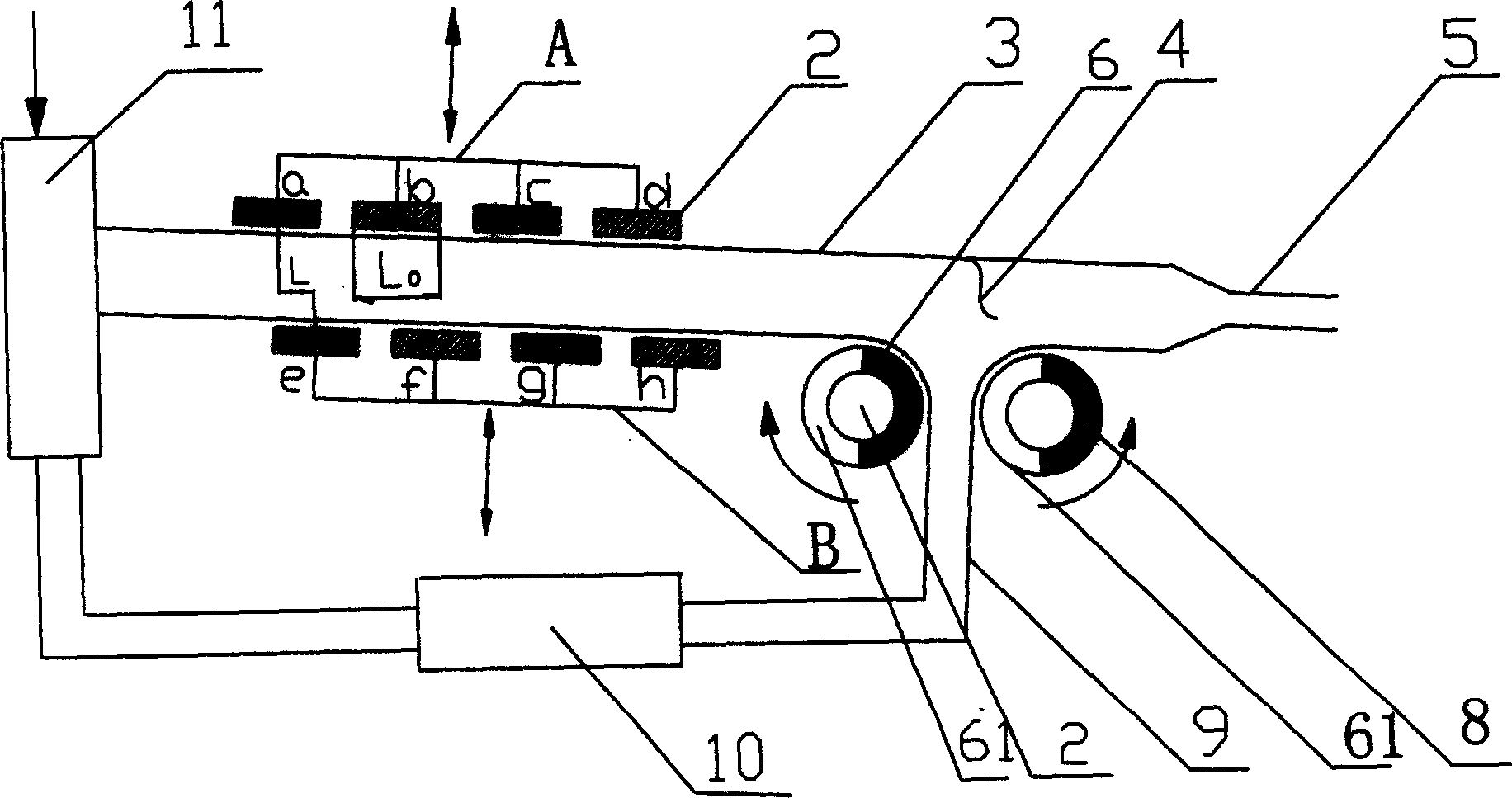

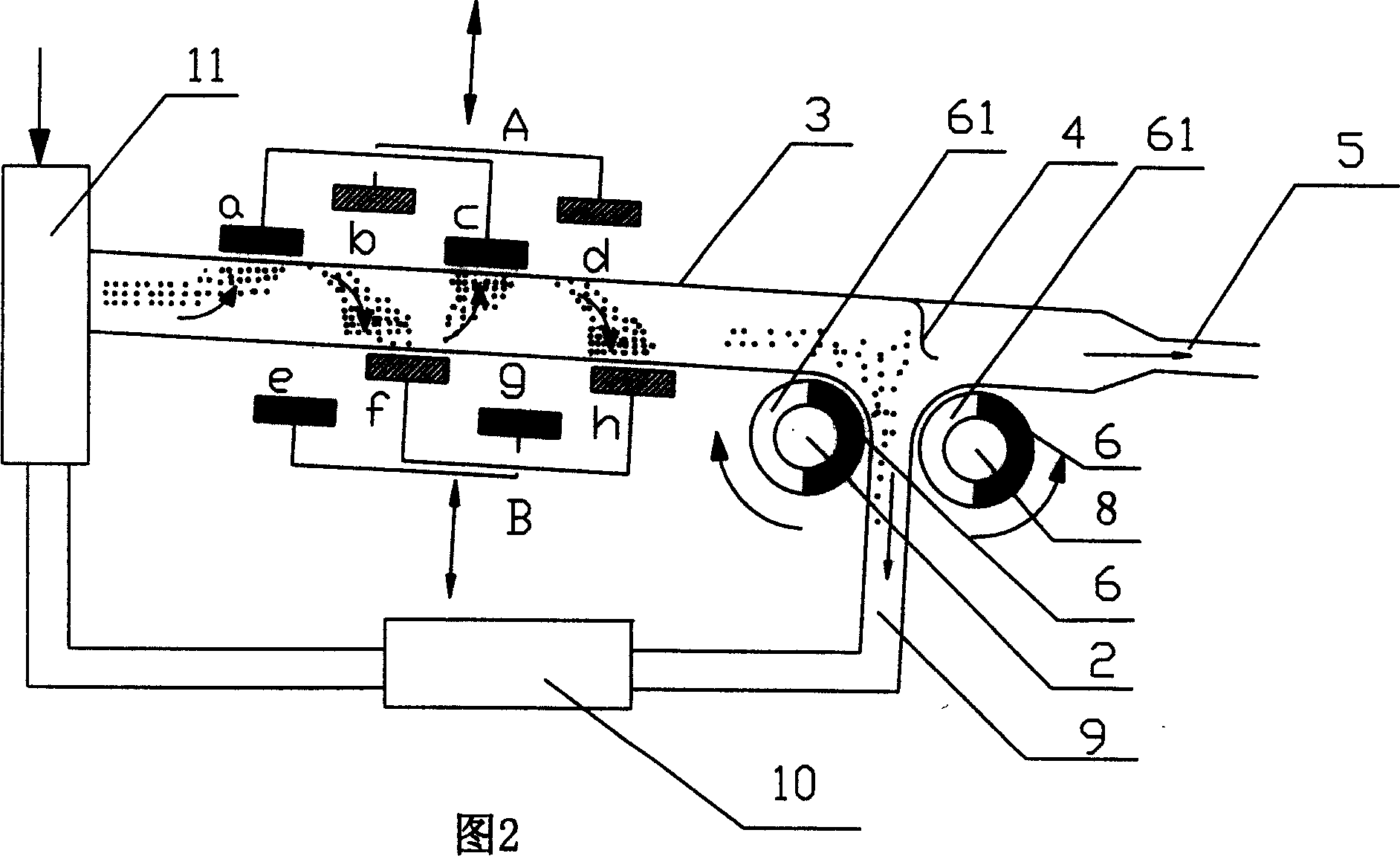

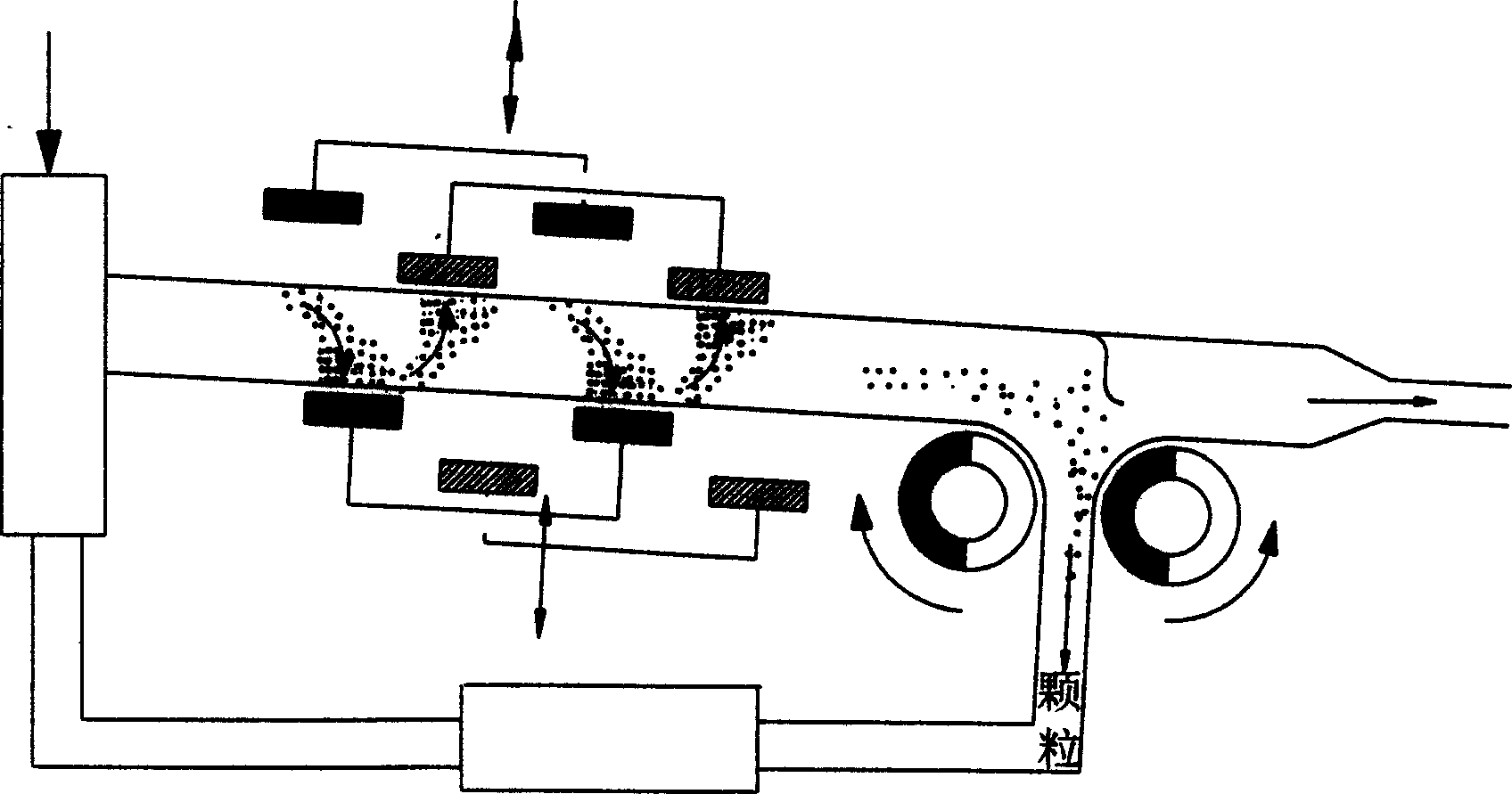

[0043] When magnets a, c, f, h are close to the surface of the reactor, magnets b, d, e, g leave the surface of the reactor, and the magnetic particles gather at the corresponding positions where magnets a, c, f, h are close to the wall of the reactor ; When magnets a, c, f, h leave the surface of the reactor, magnets b, d, e, g are close to the surface of the reactor. b, d, e, and g are gathered at the positions close to the reactor surface, such continuous reciprocating motion makes the magnetic particles form a wave motion in the rectangular reactor surface, refer to Figure 2 and image 3 . Therefore, the magnetic particles form a wave motion in the device and achieve the effect of stirring and dispersing. There is a certain residence time, and physical and chemical reactions can be carried out. Under the action of the magnetic field force on the rotating rollers 2 and 8 (the two shafts on the rotating rollers 2 and 8 drive the semicircular magnetic rings on it to rotate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com