A low energy consumption sewage treatment process and system

A sewage treatment system and sewage treatment technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of prolonged reaction time, product gelatinization, high energy consumption, etc., and achieve floating The slag collection is easy to operate, the reaction process is mild, and the product qualification rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

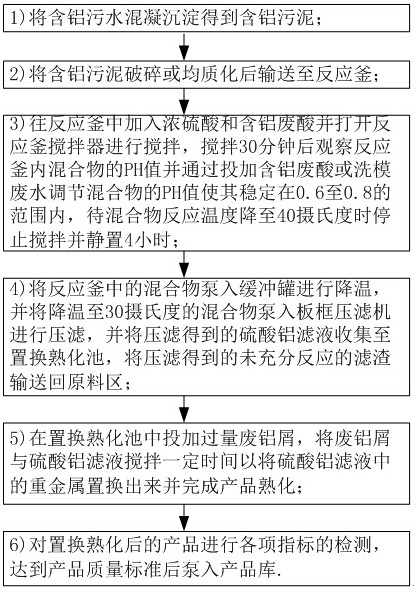

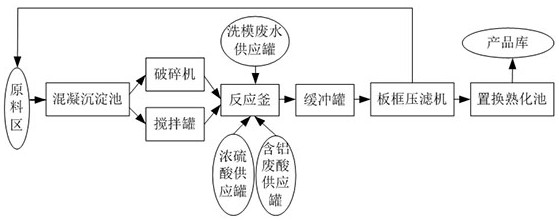

[0038] Such as figure 1 As shown, a low-energy sewage treatment process includes the following steps,

[0039] 1) Coagulate and settle aluminum-containing sewage to obtain aluminum-containing sludge. The main components of aluminum-containing sludge are aluminum: about 5%, nickel: about 0.001%, chromium: about 0.0005%, sulfates: about 14%, moisture: about 80%, and other inorganic impurities such as sediment about 1%. .

[0040] 2) After crushing or homogenizing the aluminum-containing sludge, transport it to the reactor. Specifically, the aluminum-containing sludge with a moisture content of less than 75 is crushed by a crusher and transported to the reactor by a belt conveyor; the aluminum-containing sludge with a moisture content of 75 or greater is mixed and homogenized by a mixing tank and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com