Lubricant oil pump unit

A lubricating oil pump, lubricating oil technology, applied in the direction of lubricating pump, lubricating pump pressure lubrication, pressure lubricant, etc., can solve the problems of increasing the wear of moving parts, weakening the lubricating power, high viscosity, and achieving simplified structure, light motion quality, Precisely control the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

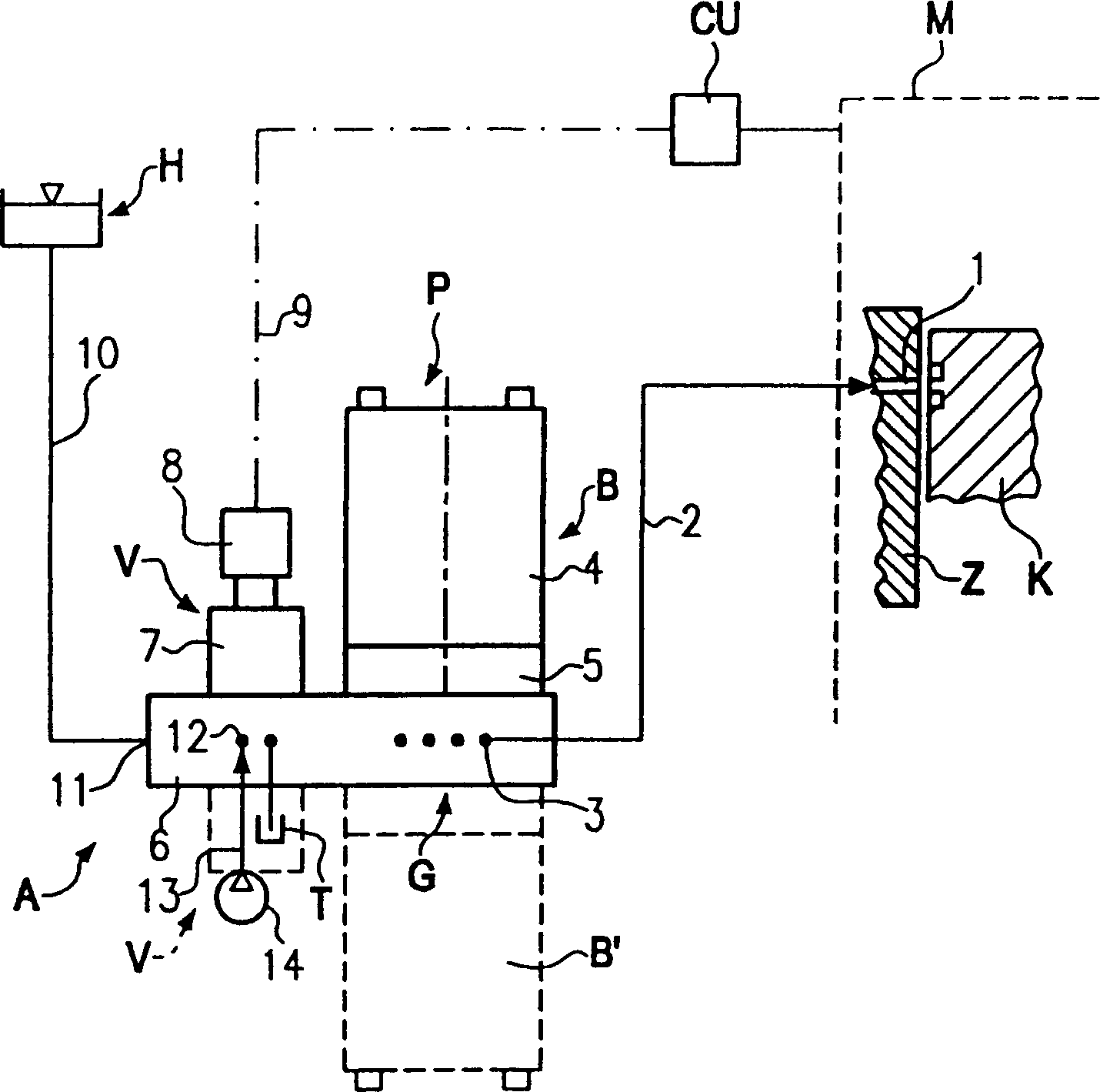

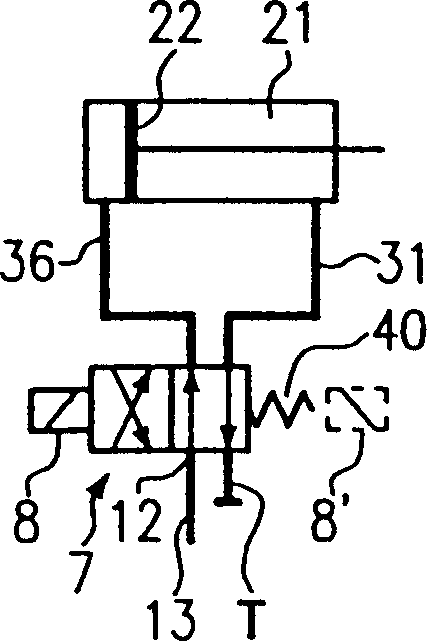

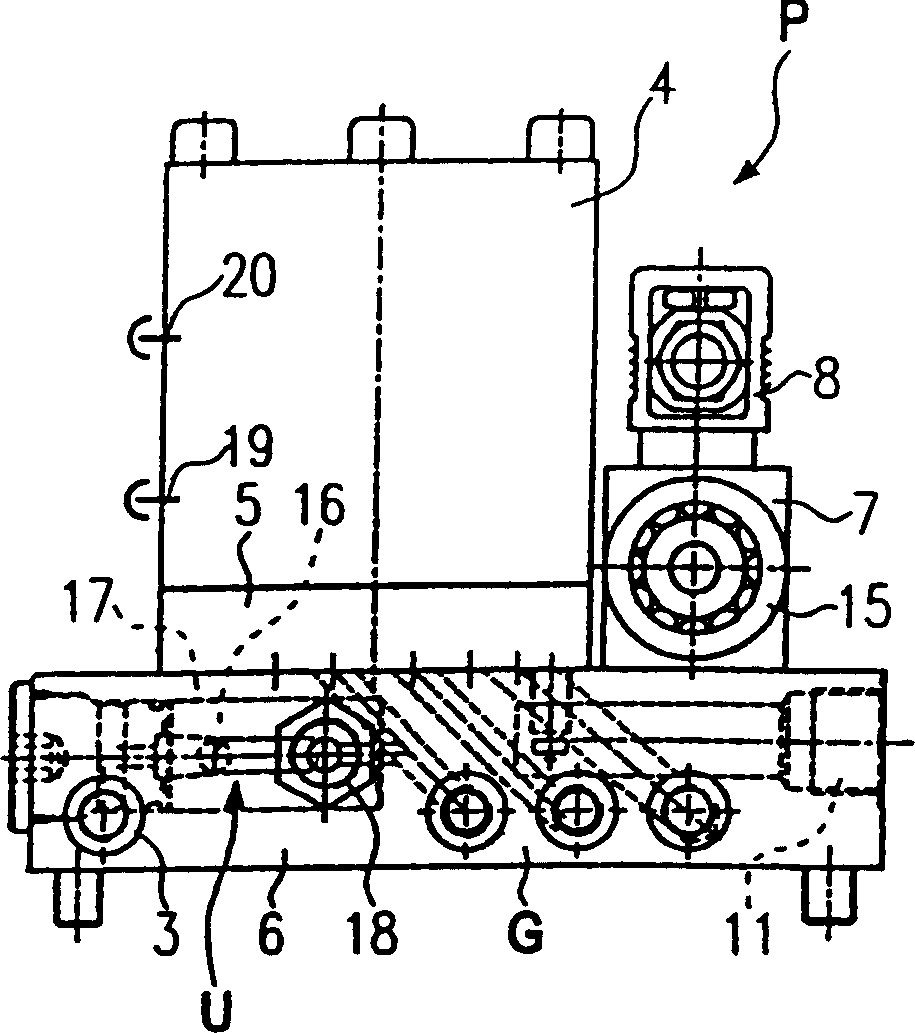

[0030] for the sake of figure 1 Lubricating points 1 on multiple cylinders of the internal combustion engine M such as diesel engines are lubricated, and a cylinder lubrication system A is set up. figure 1 Only one lubrication point 1 on the cylinder is shown in . In the above-mentioned cylinder lubricating system A, a lubricating oil pump unit P is provided to lubricate the cylinder synchronously with the working cycle of the internal combustion engine. That is to say, the lubricant, which is lubricating oil in this example, is precisely and quantitatively supplied to the piston stroke of piston K according to the above-mentioned working cycle, and its supply amount can be determined by the engine control unit CU. When the pad reaches lubrication point 1, it is either slightly ahead or behind, or when the cooling area of the piston is just aligned with lubrication point 1 (depending on the piston stroke). In this case, the lubricating oil pump unit P can be controlled pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com