Preparation method of amino acid foliage fertilizer

A technology of amino acid and foliar fertilizer, which is applied in the fields of nitrogen fertilizer, protein food processing, plant protein processing, etc., can solve the problems of unseen waste, achieve low cost, and solve the effect of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

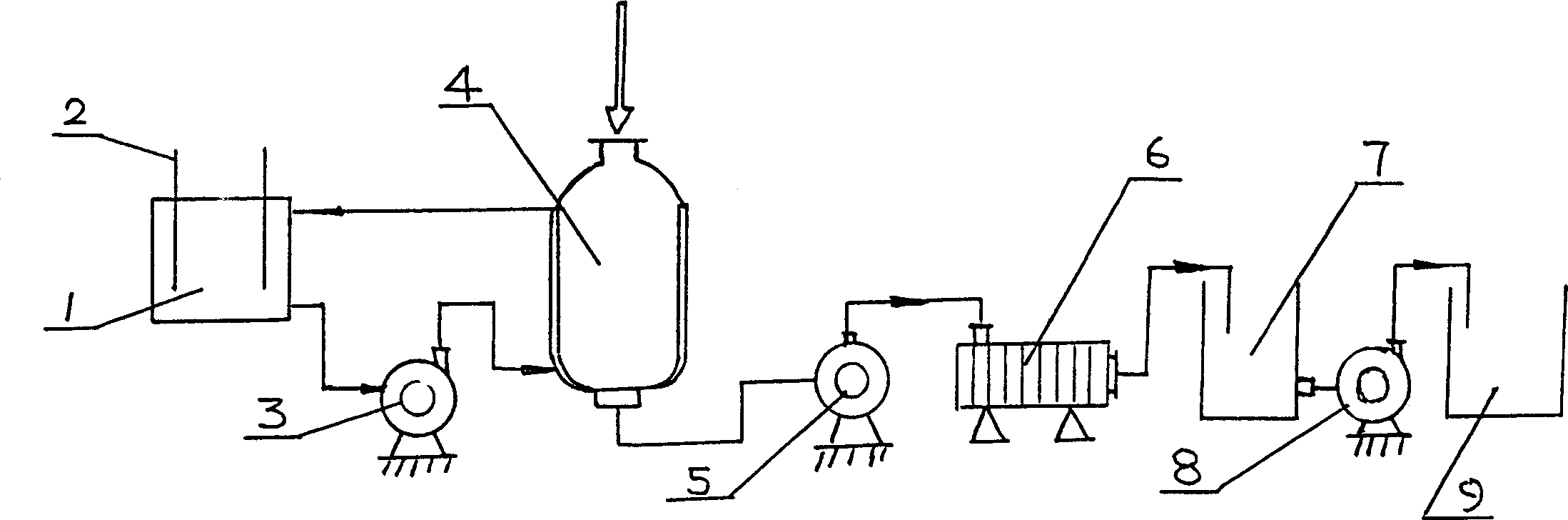

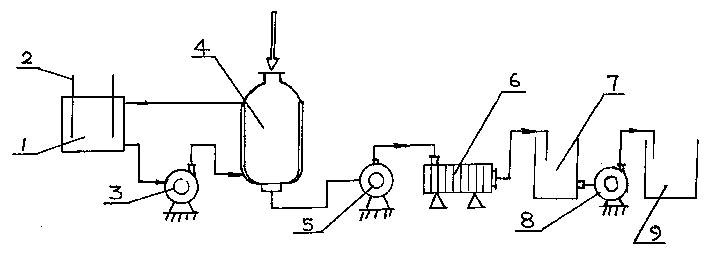

[0019] see figure 1 Electric heating cycle diagram of heat transfer oil using jacketed reactor.

[0020] Extract a ton of MSG production waste - glutamic acid-producing bacteria cells, using protease hydrolysis process: the first step is to pre-treat the cell protein, the purpose of pre-treatment is to fully denature the protein, molecular The structure is loose, so that the protein is easy to decompose under the catalysis of protease;

[0021] The pretreatment process conditions are as follows: dilute hydrochloric acid to 2%, add bacterial protein, the liquid-solid ratio is 3.5:1, then keep the heating temperature at 95±1°C, and the heating time is 1.5 hours, and the pretreatment is completed;

[0022] The second step is to move the pretreated bacterial protein to the enzyme kettle, adjust the pH=7.5, the concentration is 1:30, and the enzyme addition is 14%, and heat it. The heating temperature is 40°C and the time is 12 hours. be hydrolyzed into amino acids.

Embodiment 2

[0024] see figure 1 Electric heating cycle diagram of heat transfer oil using jacketed reactor.

[0025] Extract one ton of MSG production waste - glutamic acid-producing bacteria cells, and use the acid hydrolysis process: use sulfuric acid as a catalyst to hydrolyze the cells' protein at a certain temperature.

[0026] The process is to put the bacterial protein and dilute sulfuric acid (hydrochloric acid can also be used) adjusted to a concentration of 6N into the reactor, and the solid-to-liquid ratio is 2:3 (by weight), and heat it after sealing the kettle. The temperature is maintained at 110°C for 24 hours, the bacterial protein is hydrolyzed into amino acids, and then the lid is opened to take out the liquid for filtration and neutralization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com