Electric upsetter capable of realizing process parameter optimum control

A process parameter optimization, electric upsetting machine technology, applied in mechanical equipment, connecting components, nails, etc., can solve problems such as over-burning, discontinuous control, optimization, etc., to reduce upsetting waste, increase stability, and increase clamping. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

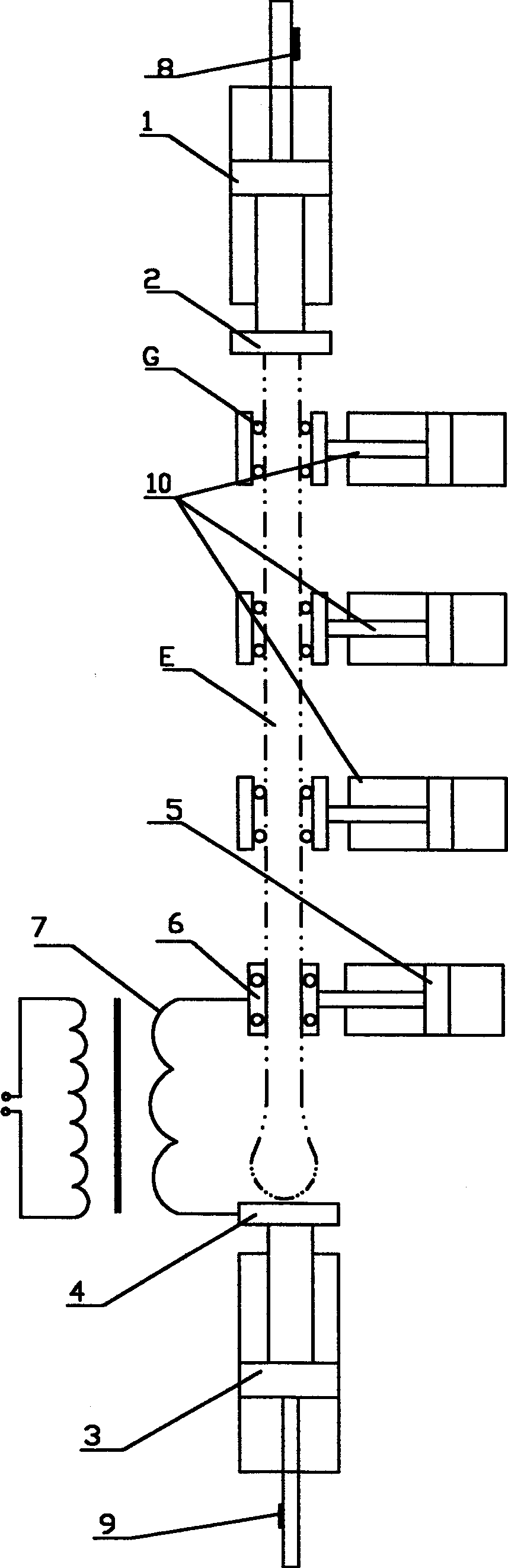

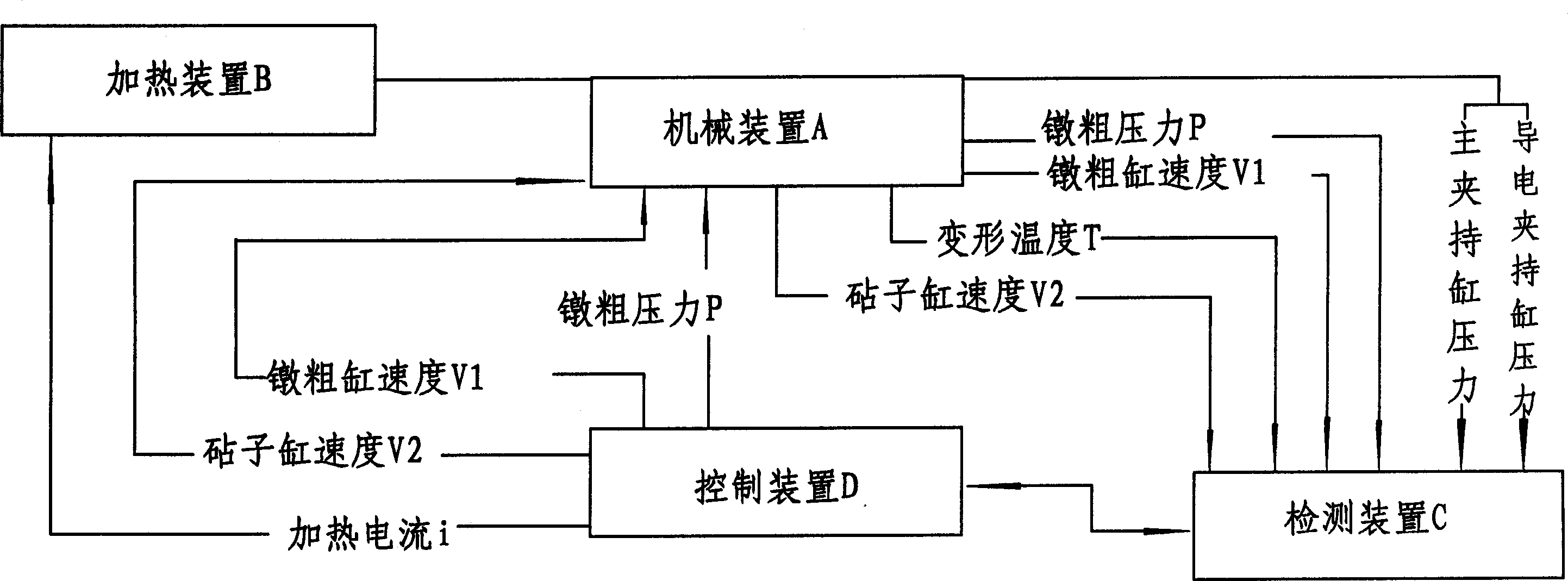

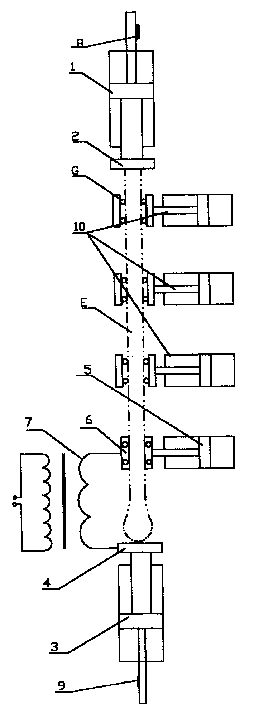

[0010] The structural principle diagram of the present invention is as figure 1 As shown, the control schematic diagram is shown as figure 2 As shown, include mechanical device A, heating device B, detection device C and its control device D, mechanical device A includes upsetting cylinder (1), upsetting block (2), anvil cylinder (3), anvil ( 4), the conductive clamping cylinder (5), the heating device B includes clamping electrodes (6), transformers (7), and the detection device C includes the upsetting cylinder (1) and the anvil cylinder (2). The displacement sensors (8, 9) on the piston, the upsetting block (2) and the anvil block (4) are fixed on the pistons of the upsetting cylinder (1) and the anvil cylinder (3) respectively, and the clamping electrode (6) is fixed Installed on the piston of the conductive clamping cylinder (5), the anvil (4) and the clamping electrode (6) are connected in series at both ends of the secondary coil of the transformer (7), and the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com