Air flow system for microwave oven

A technology of air flow and microwave ovens, which is applied in the field of microwave ovens, can solve the problems of increasing the manufacturing cost of microwave ovens, and achieve the effects of reducing manufacturing costs, improving performance, and reducing grilles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

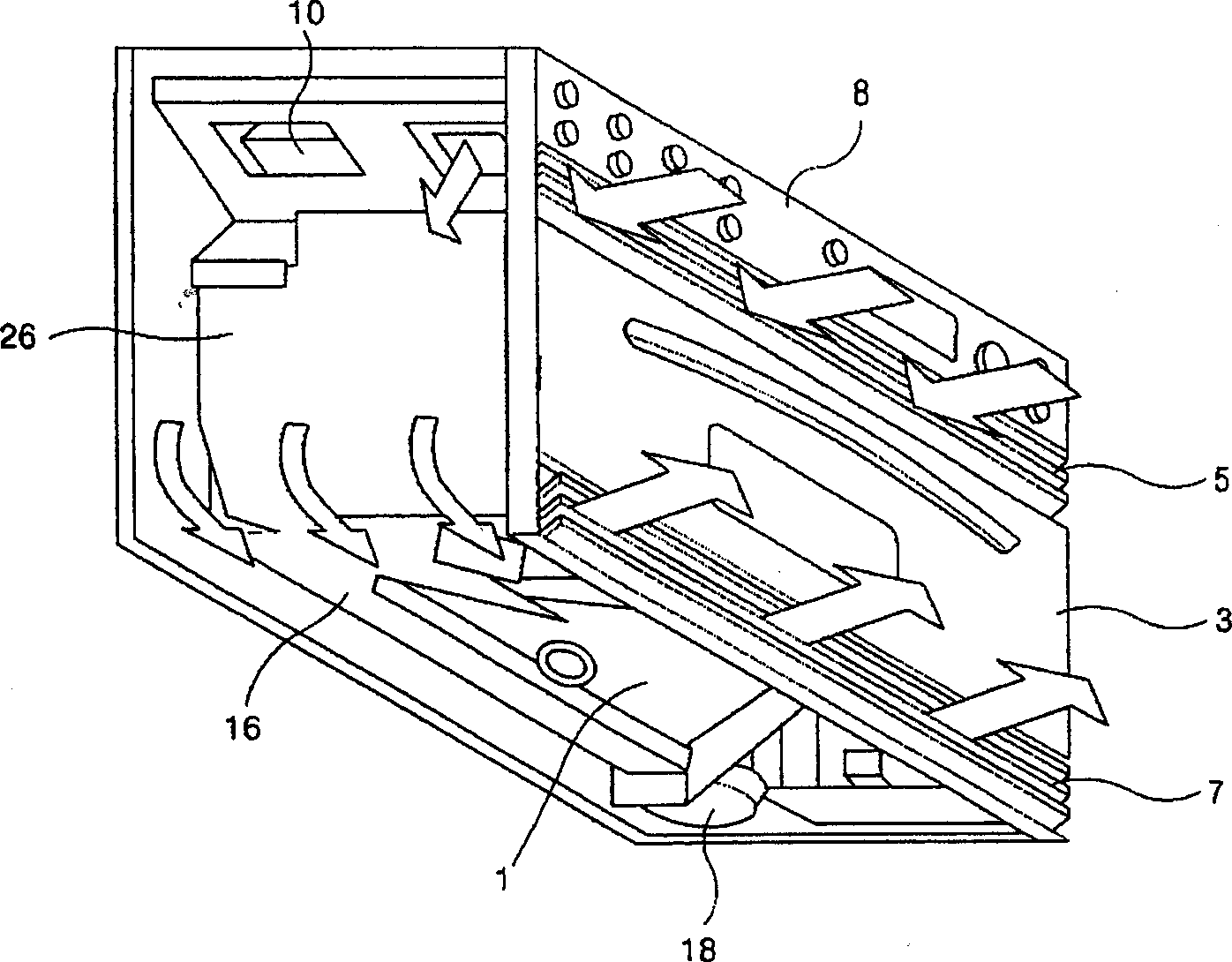

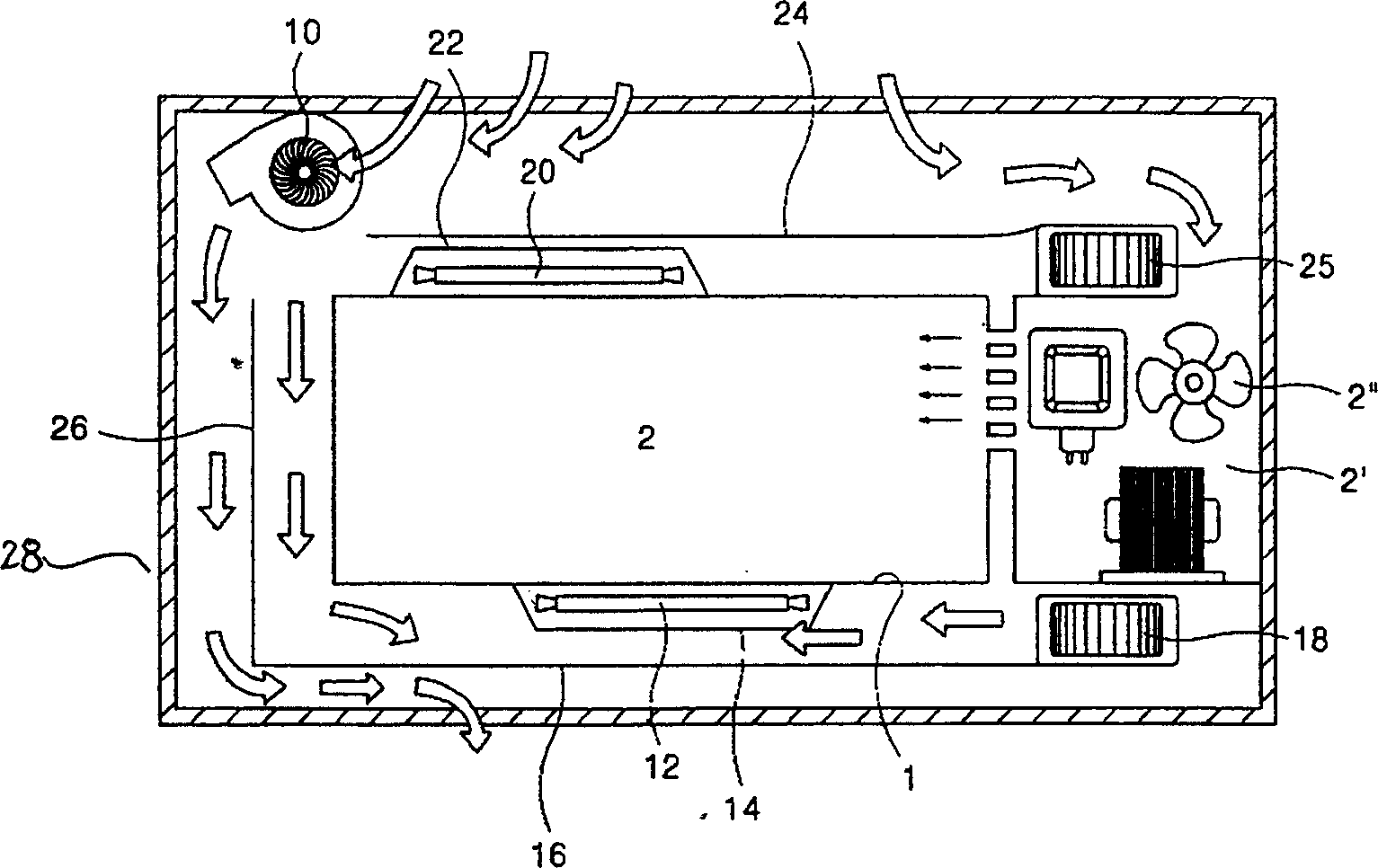

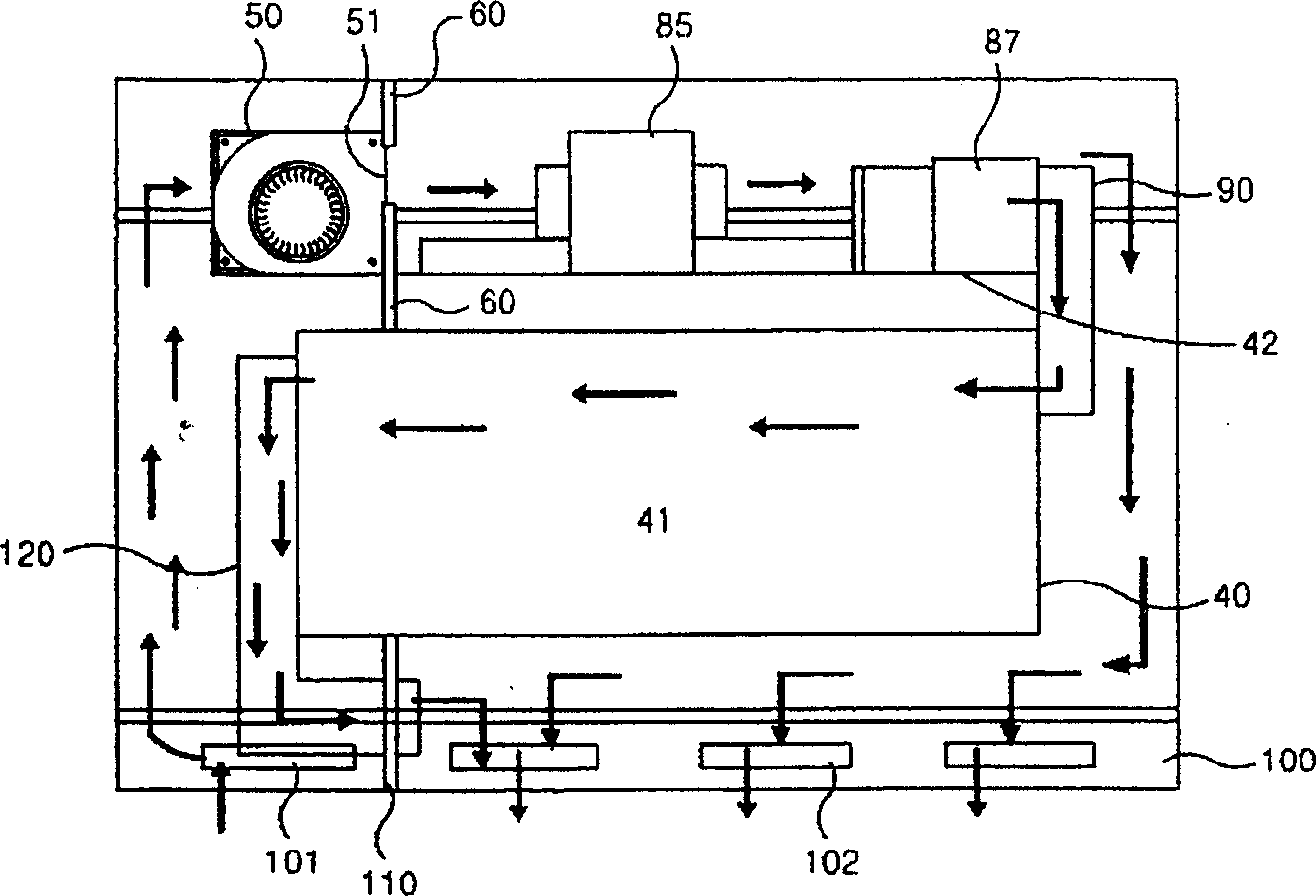

[0026] Below in conjunction with the accompanying drawings and specific embodiments, the air flow system of the microwave oven of the present invention is described in further detail:

[0027] like image 3 , 4 As shown, a conditioning chamber 41 for conditioning food is formed inside the microwave oven cavity 40 . An air flow generating device 50 is provided on the left side of the top surface 42 of the cavity, and the air flow generating device may be a suction fan assembly, the function of which is to inhale air from the outside to form an air flow inside the microwave oven. The air flow generating device 50 consists of a motor and agitating fans on both sides. The air sucked in from both ends is output through the output port 51 of the air flow generating device. A plate-shaped partition 60 including a first through hole 61 and a second through hole 62 is provided at a position corresponding to the airflow generator outlet 51 , and the partition 60 is provided adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com