Image forming device

An image and setting device technology, applied in the direction of electrical recording technology using charge graphics, image communication, equipment using electrical recording technology using charge graphics, etc., can solve the problem of ensuring the voltage stability of charge pump capacitor 15 The adjustment of the deceleration amount is difficult, the fluctuation of the rotation speed becomes large, and the adjustment of the motor drive unit 14 is difficult, etc., and the effect of small speed fluctuation, suppression of the fluctuation of the rotation speed, and low cost is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

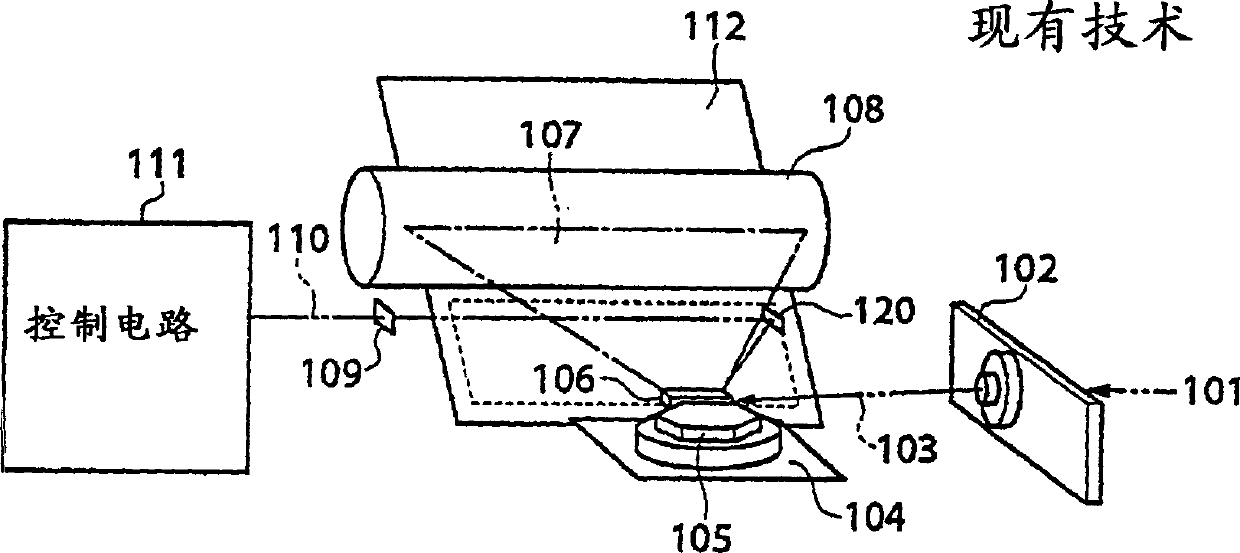

[0115] Fig. 7 is a block diagram of a polygon motor control circuit of the image forming apparatus according to Embodiment 1 of the present invention. The control circuit 111 as the polygon motor control circuit according to the first embodiment of the present invention performs various controls such as drive control of the polygon motor, and is mounted on an electrophotographic printer as an image forming apparatus.

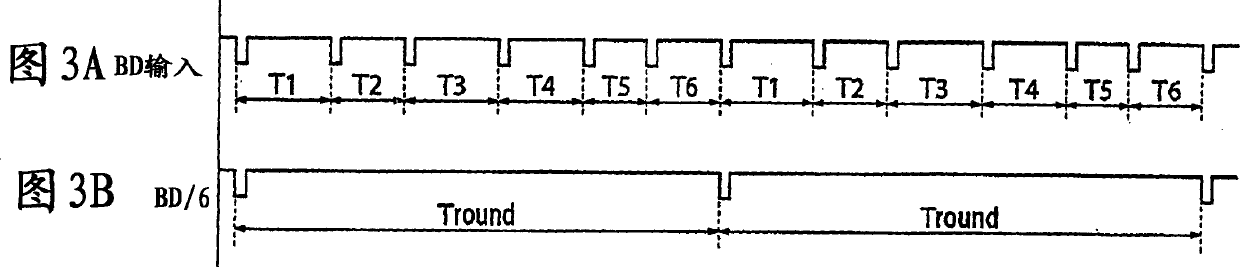

[0116] It should be noted that in FIG. 7 , the polygon motor to be controlled is schematically depicted, and the mirror 120 (see FIG. 1 ) for detecting the BD signal is omitted. In addition, since the configuration of the electrophotographic exposure scanning system is basically the same as that of the conventional polygon motor control circuit shown in FIG. 1, the same reference numerals are used for the same components, and their descriptions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com