Evaporator frost melting apparatus

An evaporator and outdoor heat exchanger technology, applied in the field of evaporator defrosting devices, can solve the problems of reducing the performance coefficient of air conditioners, indoor heat loss, and the difficulty of effective heating of air conditioners, so as to inhibit the formation or accumulation of frost, The effect of improving the coefficient of performance in winter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

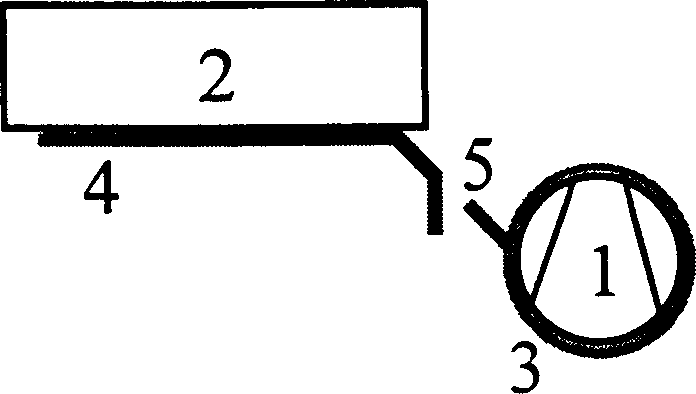

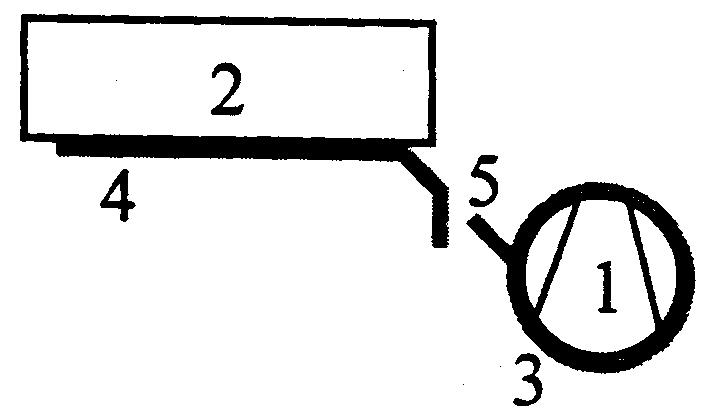

[0008] Such as figure 1 As shown, the present invention mainly includes a heat absorbing end 3, a heat releasing end 4, and a season switch 5. The heat absorbing end 3 of the defrosting device is arranged on the outer surface of the casing of the compressor 1 . The heat release end 4 of the defrosting device is arranged on the outer surface of the outdoor heat exchanger 2 . The season switch 5 of the defrosting device is installed between the heat-absorbing end 3 and the heat-discharging end 4 . The heat absorbing end 3 is composed of multiple copper strips with good thermal conductivity wound on the shell of the compressor 1 ; the heat releasing end 4 is composed of multiple copper strips with good thermal conductivity attached to the outer surface of the outdoor heat exchanger 2 .

[0009] When the air conditioner is running in summer, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com