Integrated momentum-exchange machine

An integrated exchanger and integrated momentum technology, applied in engine components, machines/engines, air quality improvement, etc., can solve the problem that the honeycomb structure is prone to blockage, affect the dynamic performance of motor vehicles, and reduce CO, HC, and HC in motor vehicle exhaust. NOX emission concentration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

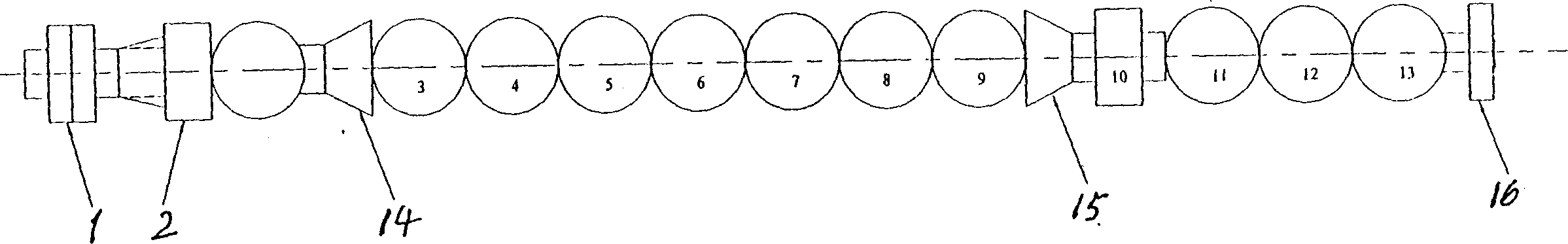

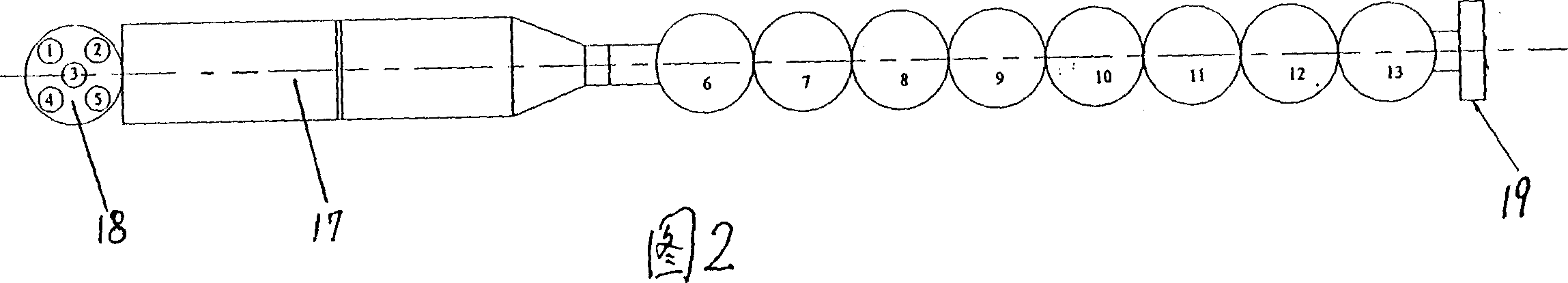

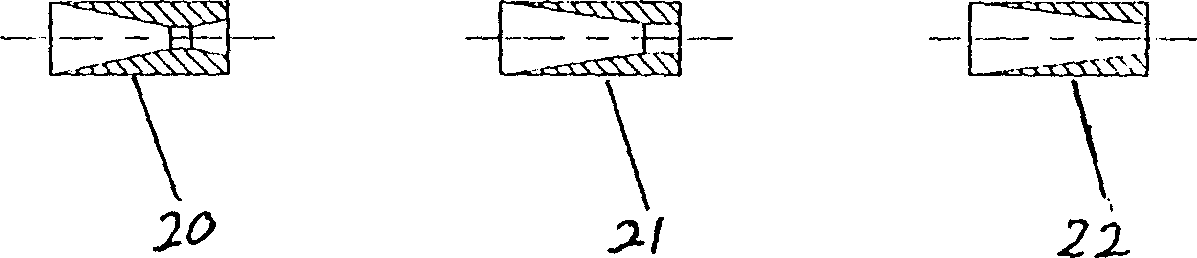

[0018] The integrated momentum exchanger is composed of 13 primary and secondary integrated exchange devices. Except that the first-stage main exchanger is directly connected with the exhaust port of the motor vehicle engine, the other stages are fastened into a whole through the connecting channel by screw fastening. The primary and secondary exchangers integrated with momentum exchangers are connected in parallel to form a whole.

[0019] The processing material of the integrated momentum exchanger is easy to obtain. It can be made of high-temperature-resistant and non-skinning stainless steel, or it can be made of corrosion-resistant aluminum alloy. In order to reduce the cost, it can also be made of ordinary steel. The processing method can be completed by machine tool cutting and drilling machine drilling. In order to meet the needs of mass processing, it can also be obtained by precision die-casting.

[0020] The practical size of the integrated momentum exchanger can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com