Light-weight assembly type heat insulation plates for grain warehouse and its manufacturing technique

A granary, light-weight technology, applied in the field of prefabricated granary construction, can solve the problems of inability to achieve sealing, moisture-proof and insect-proof, poor thermal insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

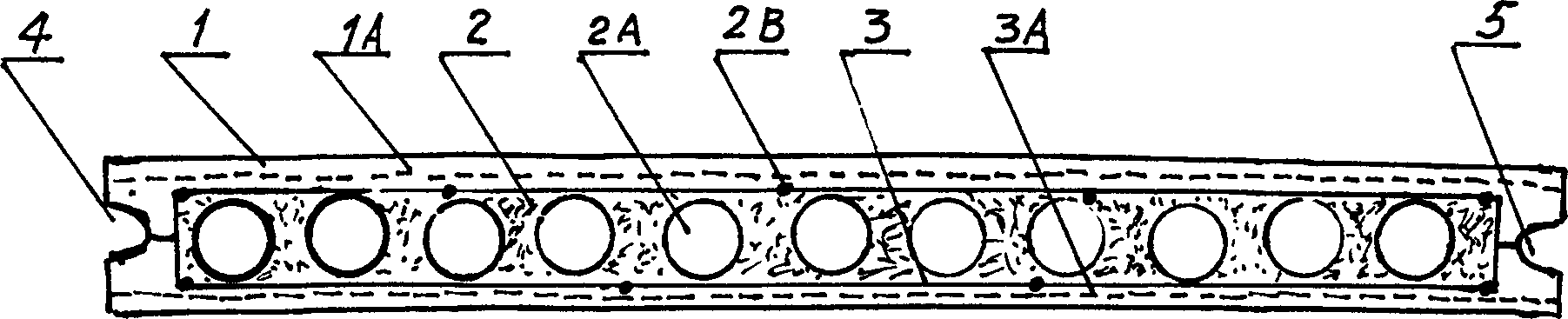

[0012] specific implementation plan

[0013] In order to make the outer surface layer 1 have a more decorative effect, in addition to the cement mortar with the ratio of 525# quick-hard sulfoaluminum cement and medium sand, cement pigments can also be specially added to produce a more obvious decorative effect. The weight ratio of the added pigment to cement is 1:0.04-1:0.06. In order to further improve its appearance characteristics, an appropriate amount of concrete brightener can also be added to the proportion of the outer layer 1. When using white dye as decorative color, a small amount of white cement can be added to further improve its aesthetic feeling.

[0014] The raw materials for making the core layer 2 are 525# quick hard sulfoaluminum cement and lightweight filler. The lightweight filler can use saw foam, rice husk or straw fiber. Taking saw foam as an example, the weight ratio of the added lightweight filler to 525# rapid-hardening sulfur-al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com