Communication cable whose insulated conductors are parallelly-opposite-arraged into bundle

A technology for communication cables and insulated conductors, applied in communication cables, plastic/resin/wax insulators, cables with twisted strands/quad strands, etc., can solve the problem of reducing attenuation characteristics, signal transmission effects, synthetic foam The medium is easy to be crushed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] The performance of cables with oppositely twisted pairs and bundles compared to cables with oppositely twisted pairs and bundles was tested.

[0033] Both cables were tested, each with four twisted pairs of insulated conductors, and the specifications are given in Table 1.

[0034] feature

value

Conductor size

24 gauge

conductor material

American Wire Gauge Copper Wire

insulator material

3 pairs foam / skin PVC; 1 pair foam / skin PE

Insulator Thickness

0.007 inches

insulator coaxial capacitor

Fluorinated ethylene propylene min 52, max 57, polyethylene 61 (picofarads / ft)

cable length

328 feet

envelope material

PVC compound (rated for high pressure)

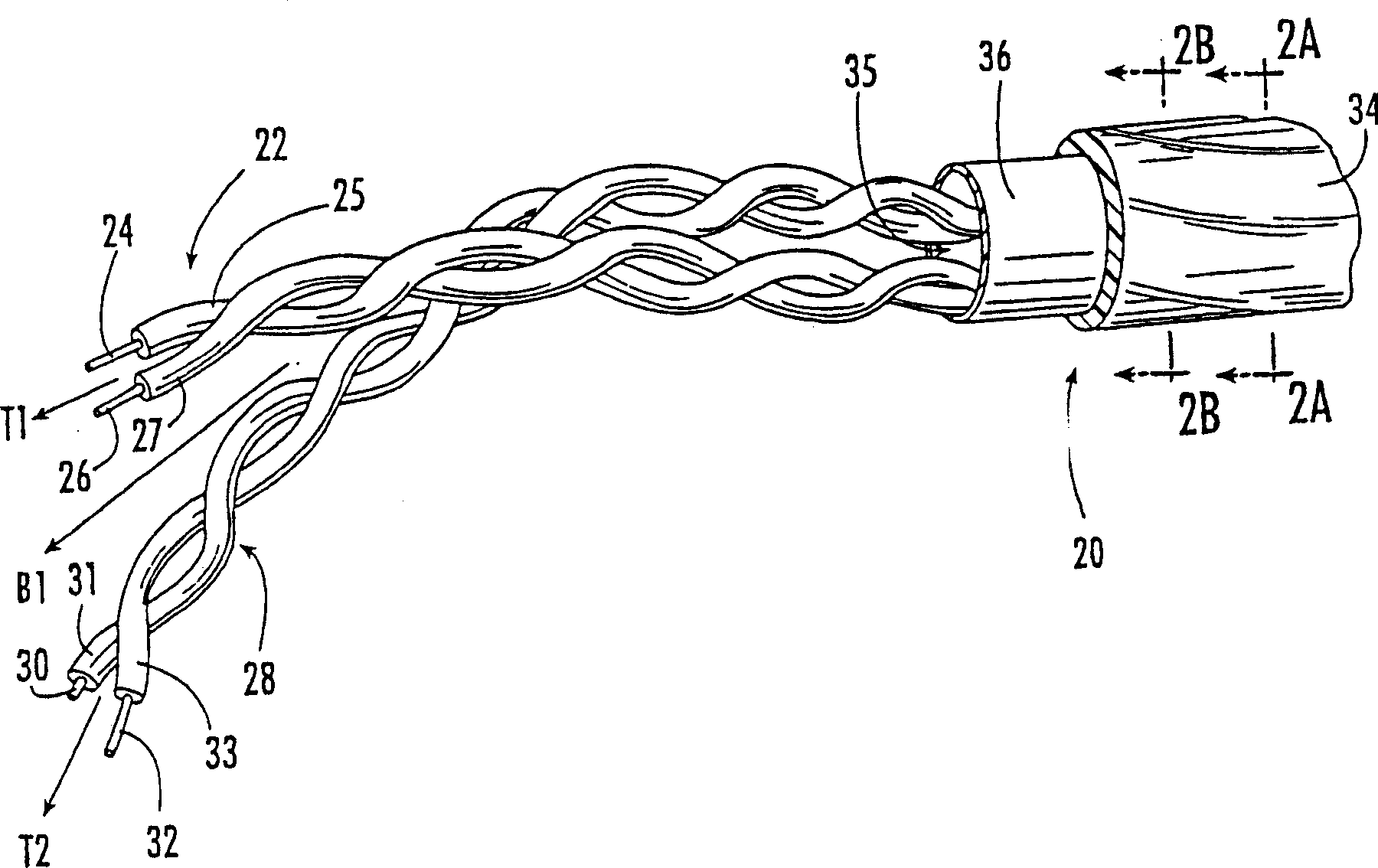

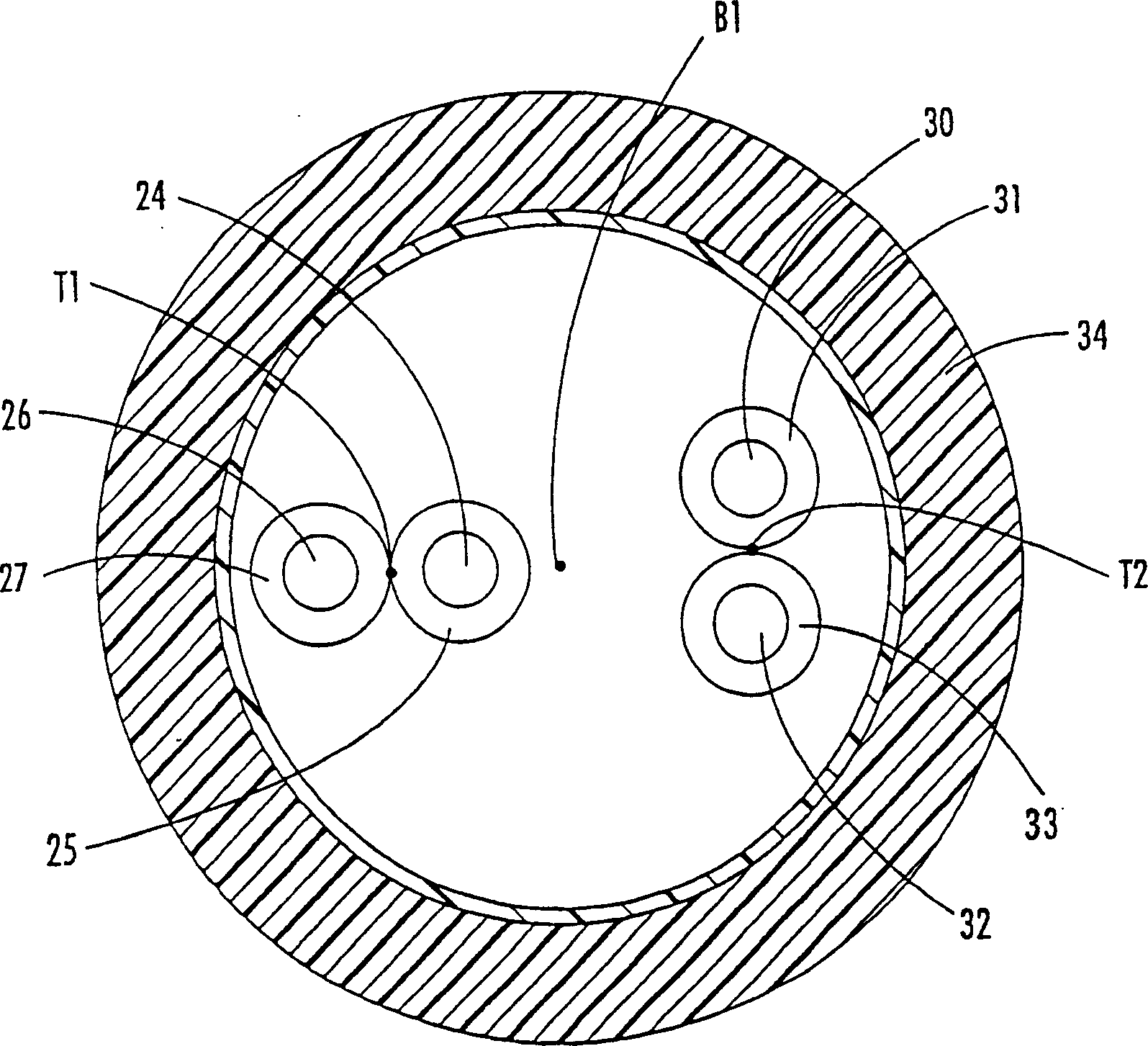

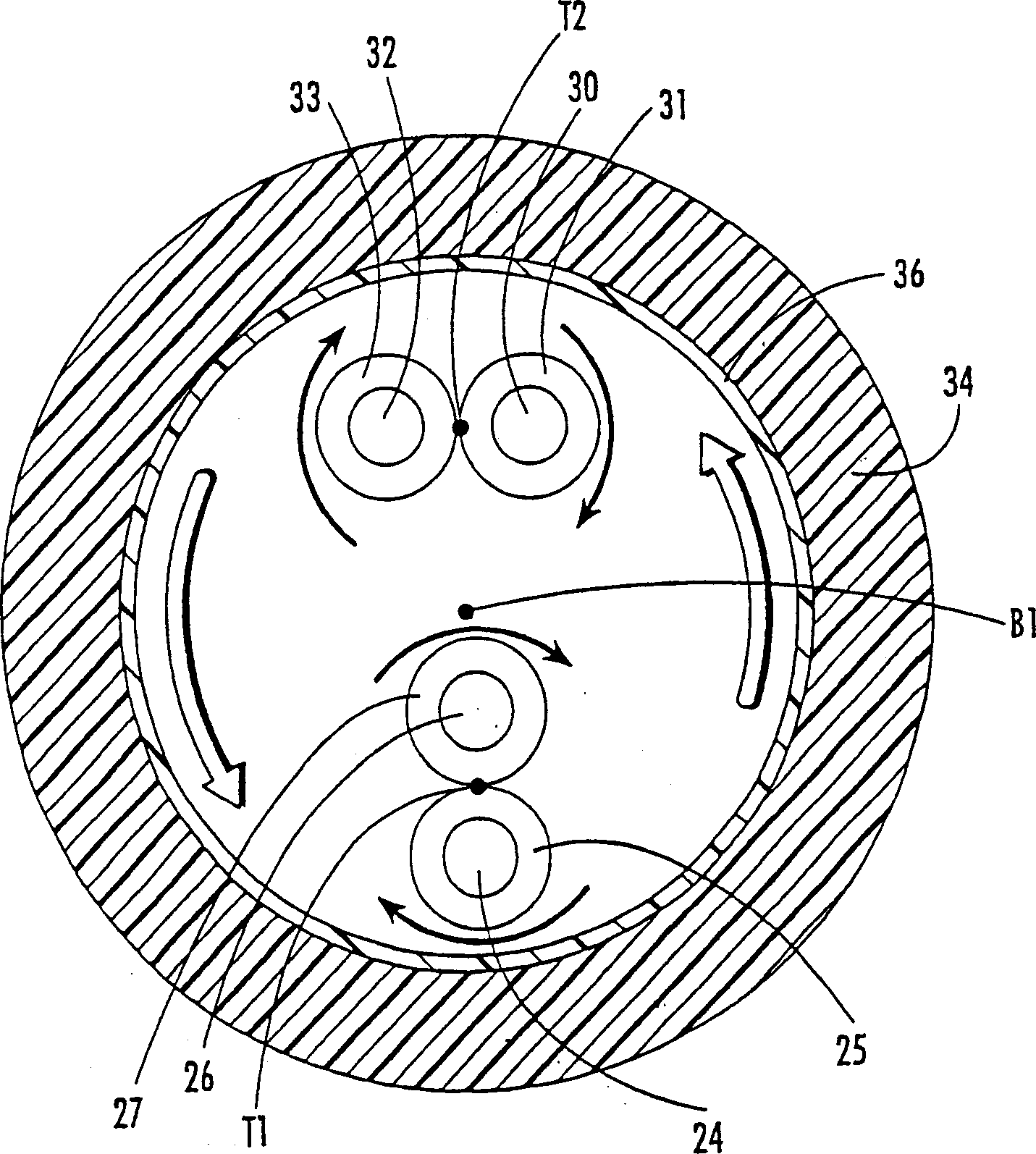

[0035] The twisted pairs of each cable are twisted in a counterclockwise direction with a twist length of 0.45 to 0.8 inches. One cable (cable 1) is bundled clockwise (i.e. twisted and bundled in opposite directions) with a 6" lay ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com