Flow control valve and sphygmomanometer

A technology for flow control valves and inflow ports, which is applied to valve details, valve devices, blood vessel evaluation, etc., can solve problems such as insufficient crimping force, increased power consumption, and enlarged size, and achieves small size, low power consumption, and poor operation Effects with few, simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is illustrated below by means of examples.

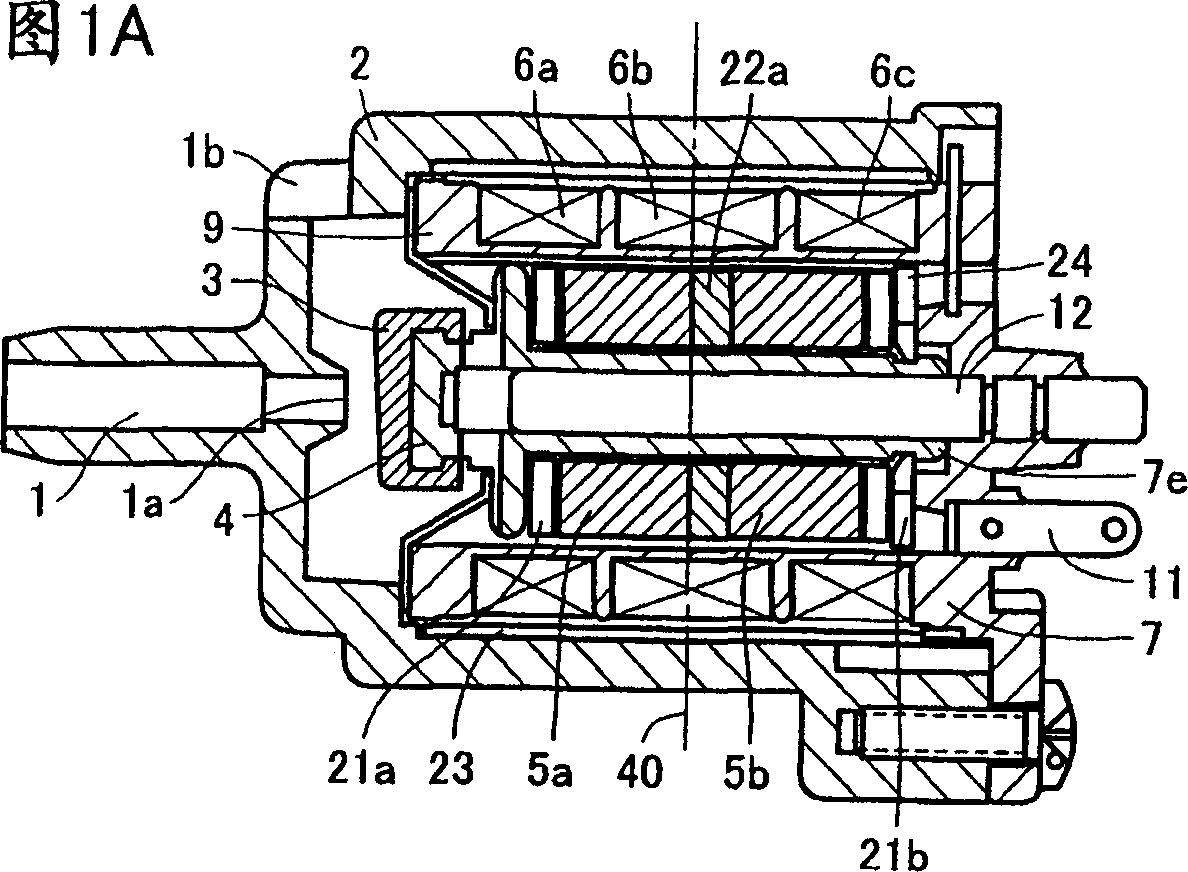

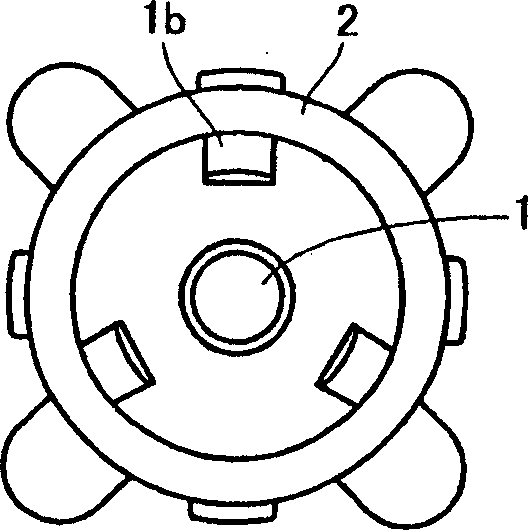

[0049] The flow control valve of one embodiment thereof is shown in Fig. 1A (schematic sectional view) and Figure 1B (left side view). On the other hand, the same symbols are assigned to the same elements as those shown in FIGS. 15A and 15B .

[0050] The flow control valve of this embodiment has used two permanent magnets 5a, 5b and three electromagnetic coils 6a, 6b, 6c; The housing is formed by the rear part of the frame housing 2 and the coil skeleton 7 equivalent to the aforementioned front cover, This housing (frame housing 2 ) has a gas inlet 1a in which a nozzle-shaped inner pipe 1 opens, and a plurality (here, three) of gas outlets 1b communicating with the gas inlet 1a through an internal space.

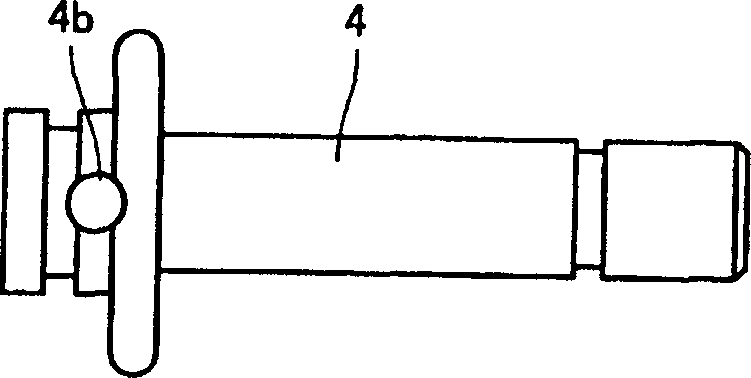

[0051] Inside this housing, Figure 2A , 2B The shown hollow actuating shaft (movable member) 4 can be arranged forwardly and backwardly with respect to the inflow port 1a. In order to open and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com