Reaming method for pile hole of building and reaming bit for screw drilling machine

A technology of helical drilling and reaming drills, which is applied in construction, earth-moving drilling, drill bits, etc., can solve the problems of low forming and expanding efficiency, inaccurate dimensions, collapse forming, etc. Simple, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The structure of the present invention is further described in conjunction with the accompanying drawings provided in the embodiments:

[0028] The invention is matched with the existing spiral drilling machine to expand the formed straight pile hole. The helical drilling machine mainly includes the motor, the power part of the gearbox and the hollow drill pipe with helical blades; in addition, the chassis adopts full hydraulic walking, and the hydraulic motor drives the slewing bearing to rotate 360°.

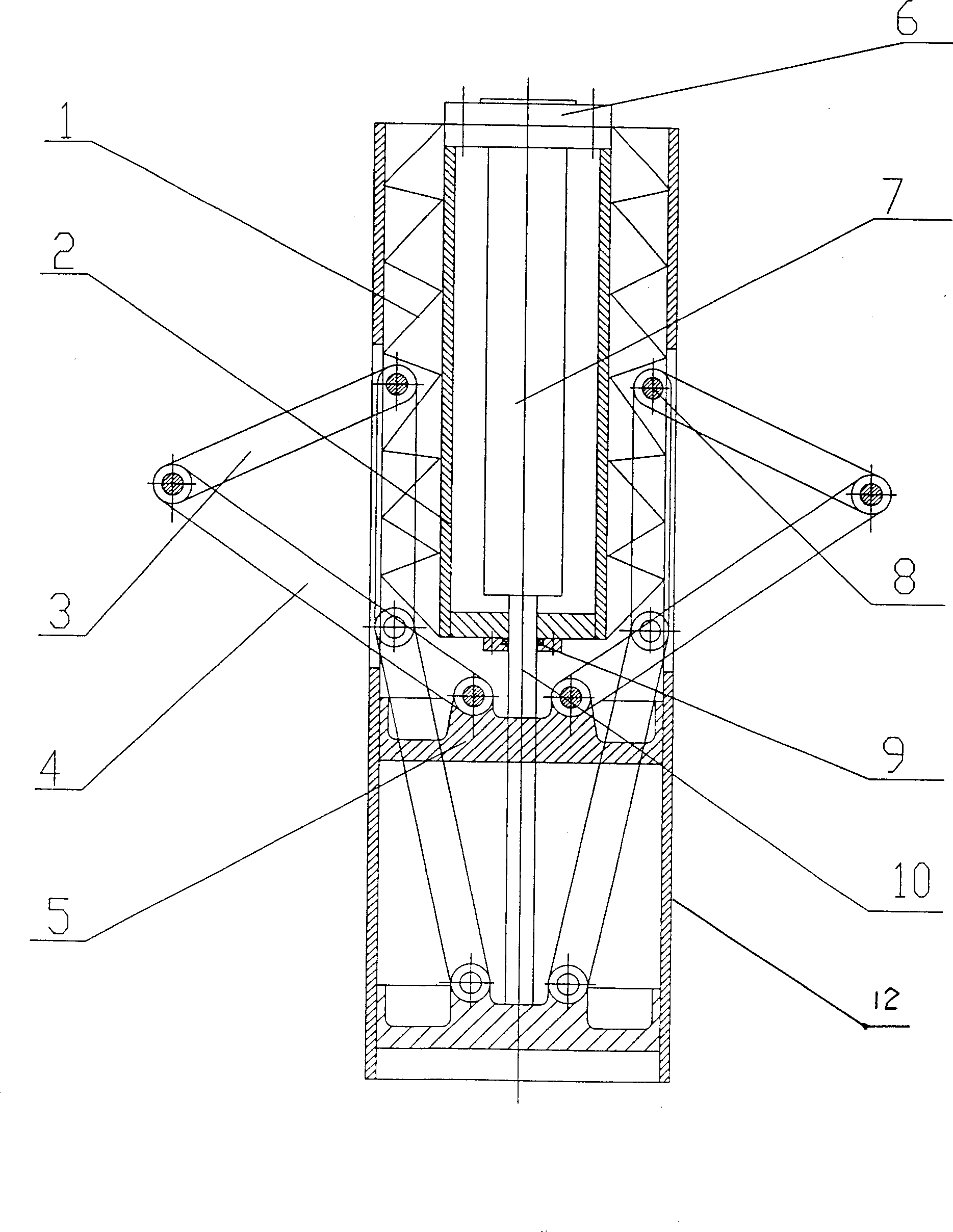

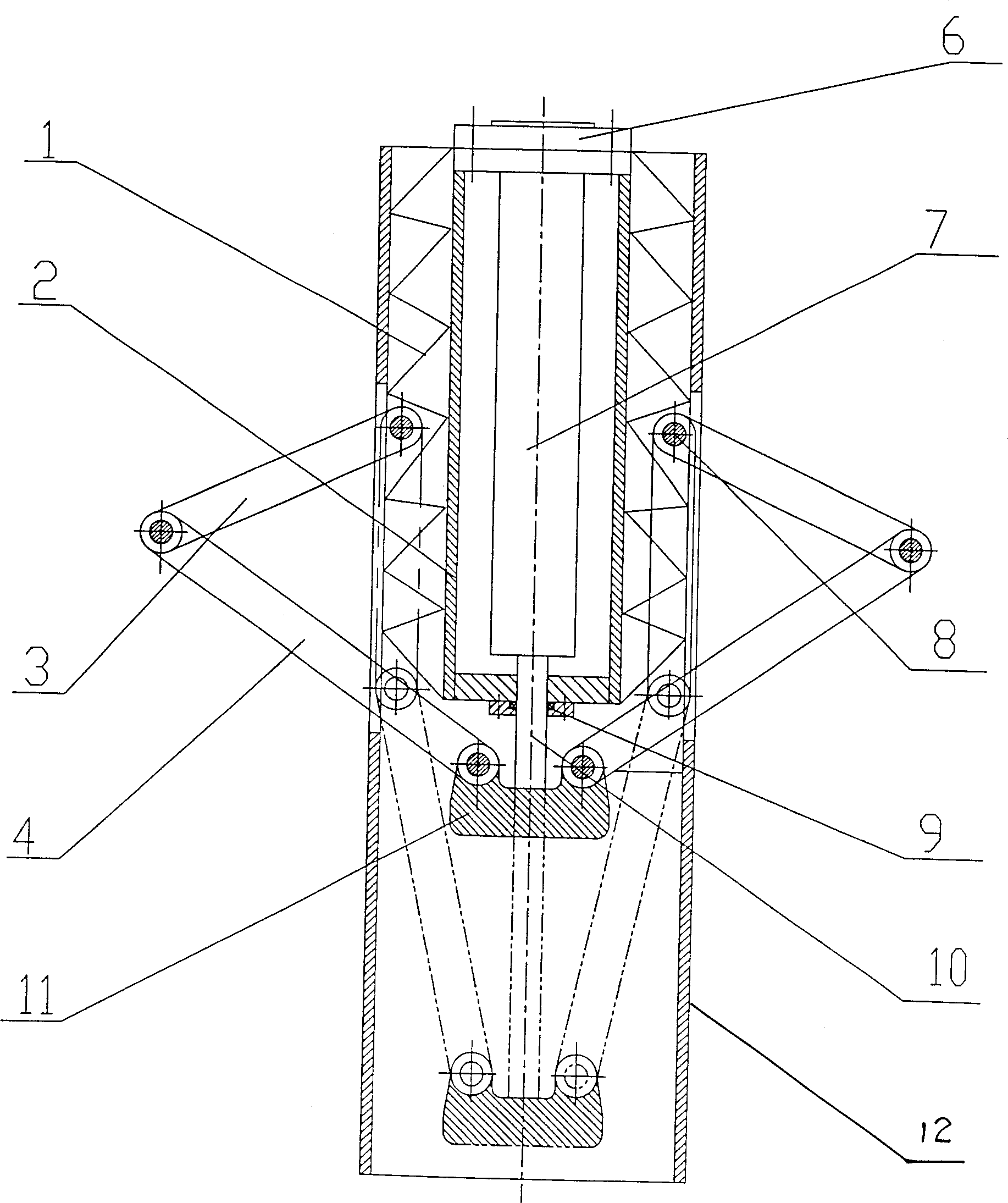

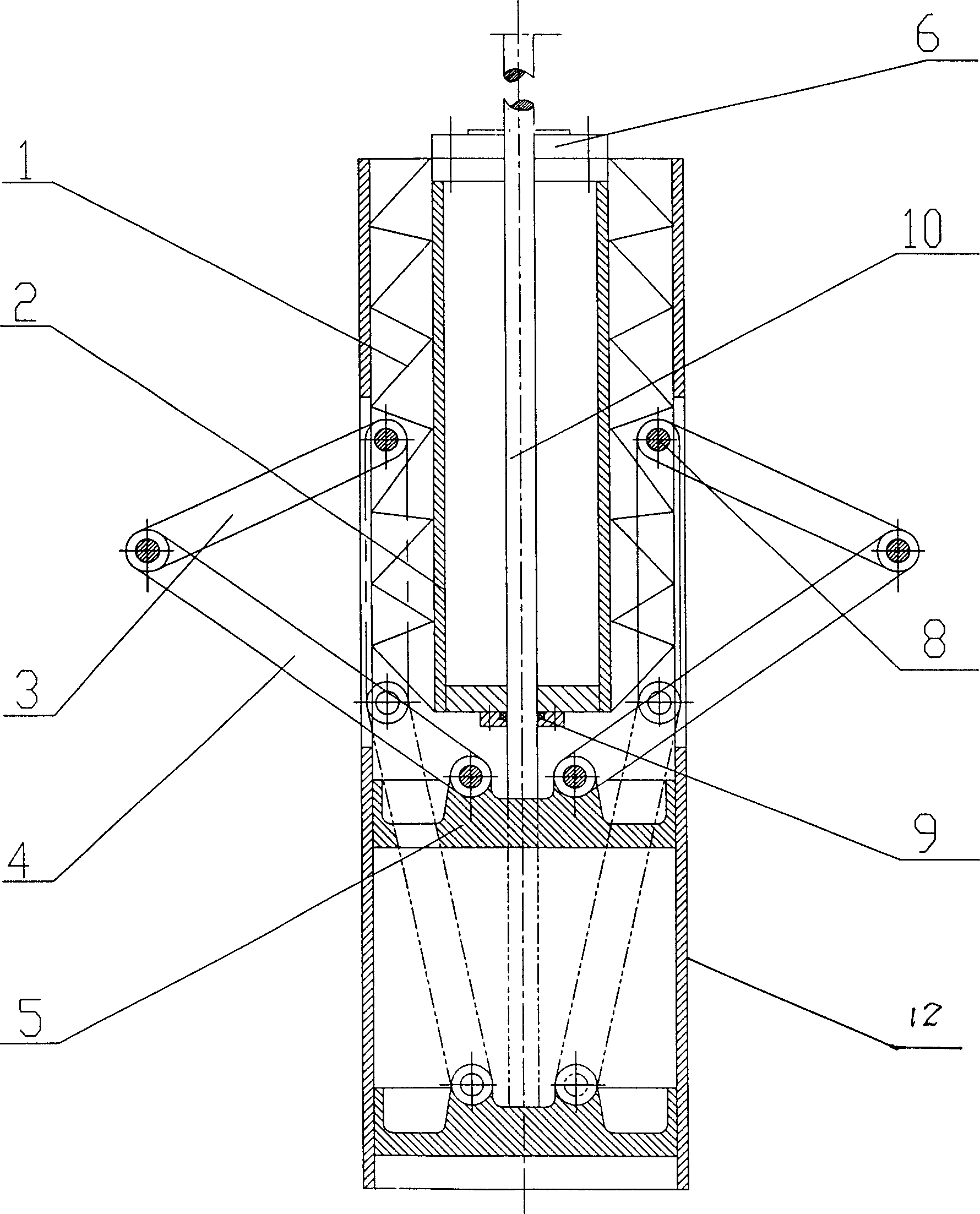

[0029] as attached figure 1 As shown, the present invention has an inner pipe 2, and the inner pipe is connected with the drill pipe of the auger drilling machine through a flange 6. The outer circumference of the inner pipe 2 has a helical blade 1 , and the helical blade 1 has an outer sleeve 12 rigidly connected with the helical blade as a whole. Wherein the radius of the outer sleeve 12≤the radius of the helical blade of the drill pipe. A lifting device is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com