Method for preparing kraft cardboard paper

A kraft box and cardboard technology, applied in the papermaking industry, can solve the problems of increasing waste water treatment load and equipment power consumption, poor paper interweaving in the net part, and affecting the water filtration speed of the net part, so as to improve the water filtration speed of the net part , improve the operating rate of the paper machine, and have a good effect of interweaving paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

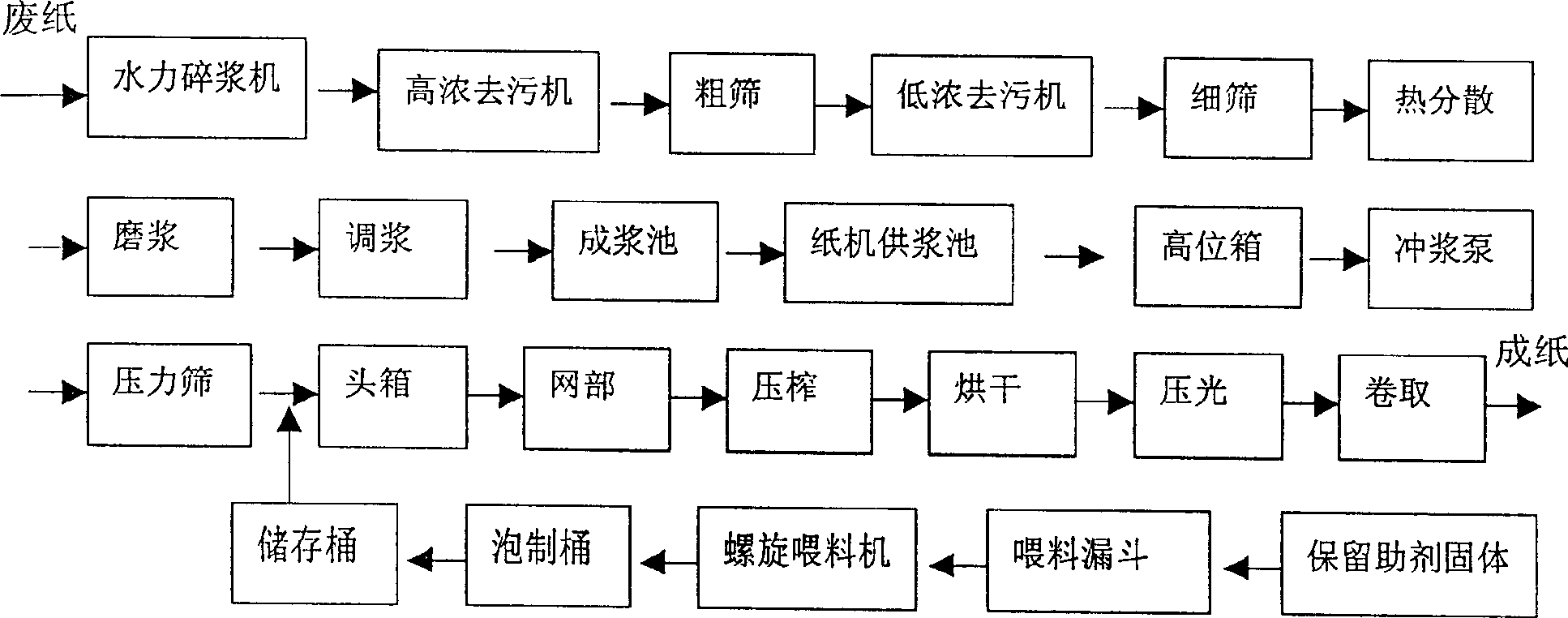

[0017] Process flow of the present invention is as follows:

[0018] In the present invention, the imported waste paper is transported to the pulper through the feed machine for disintegration. The liquid level of the pulper is set at 65-67%. 3% to 3.6%. The disintegrated pulp first passes through a high-concentration decontamination machine to remove heavy impurities such as metals and stones, and then passes through a coarse sieve to remove some relatively large impurities, such as paper pieces, hard plastic pieces, straw ropes, etc. The good pulp from the coarse screen is removed by the low-consistency decontamination machine to remove some light impurities and heavy impurities whose specific gravity is different from that of the fiber. : 0.8~0.9% (weight percentage). The fine pulp from the low-consistency decontamination machine goes to the fine sieve to further remove some impurities that are different in size and shape from the fiber. The fine sieve has two sections, w...

Embodiment 2

[0025] Adopt the technological process among the embodiment 1, add solid retention aid after the pressure sieve operation, through feeding funnel, suck in brewing barrel by screw feeder again, add water in brewing barrel, retention aid is mixed with 0.23 % (percentage by weight) concentration, the prepared retention aid liquid is sent to the storage tank with a pump, and the addition amount of 0.04% (percentage by weight) is continuously added to the outlet of the pressure sieve with a metering pump, and the full set of production in Example 1 is adopted It can also produce kraft linerboard with good formation, high quality and high output.

Embodiment 3

[0027] After the pressure sieve process of the present invention, add the solid retention aid, through the feeding funnel, suck the brewing barrel by the screw feeder, add water in the brewing barrel, the retention aid is mixed with a concentration of 0.25% (percentage by weight), use The pump sends the prepared retention aid liquid to the storage barrel, and continuously adds it to the outlet of the pressure screen with a metering pump in an amount of 0.045% (percentage by weight), and adopts the process production method in Examples 1 and 2, which can also produce Produce high-quality kraft cardboard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com