Method of producing carbon monoxide and hydrogen using methanol and reactor used

A carbon monoxide and reactor technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, hydrogen, etc., can solve problems such as inability to produce carbon monoxide, low concentration of carbon monoxide, inability to separate and use alone, etc. Achieve long service life, easy storage and transportation, and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

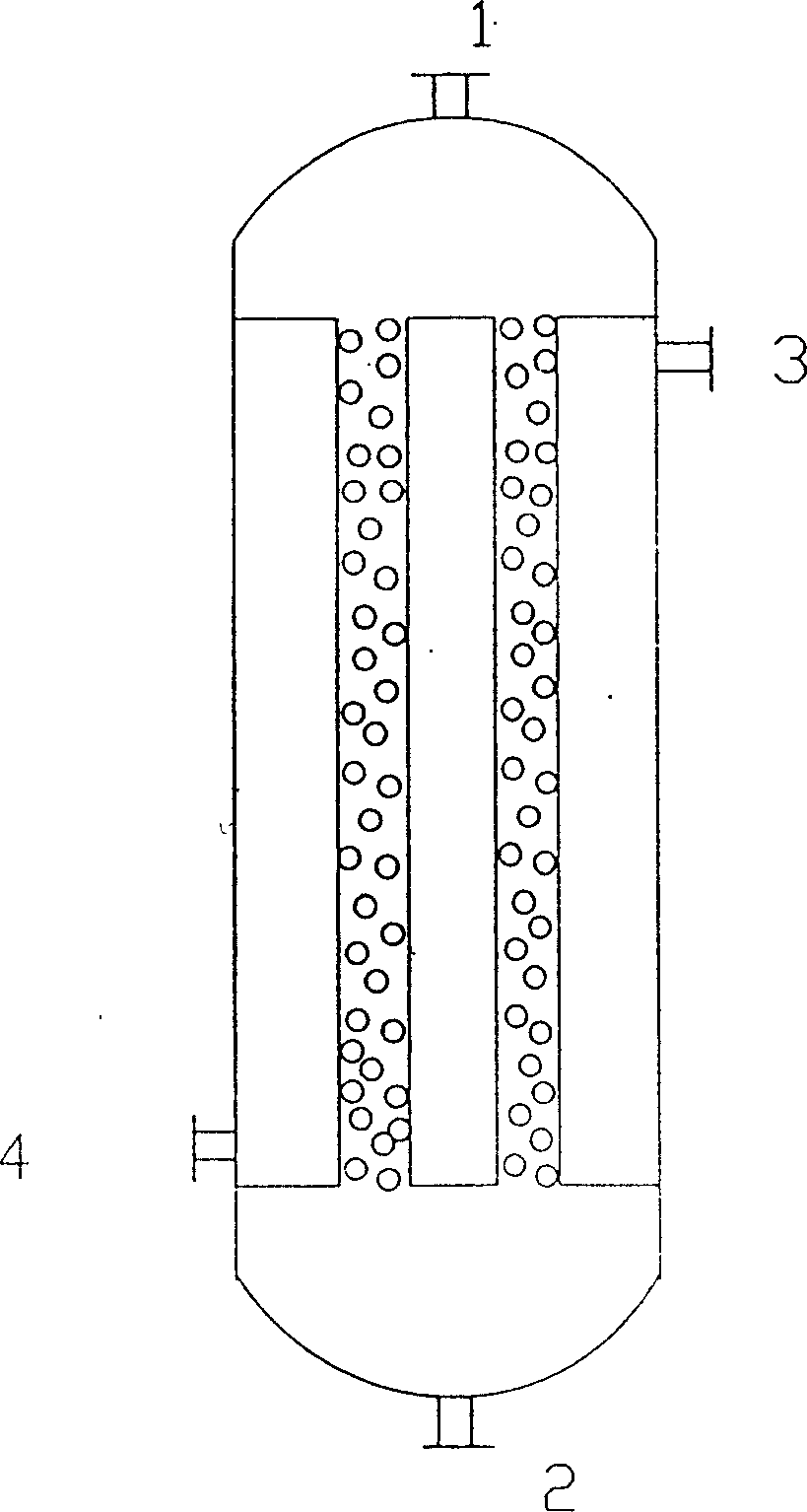

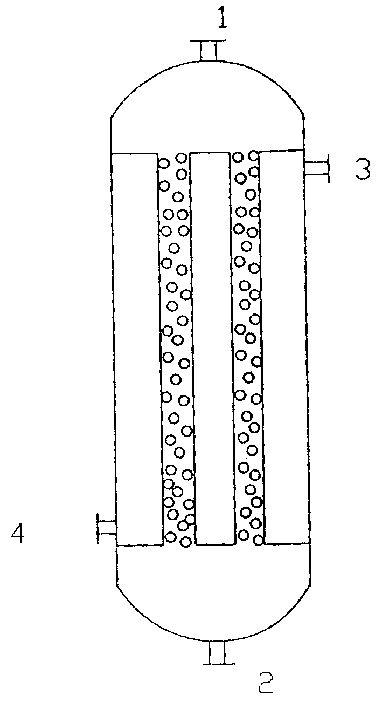

[0019] Take 1 molar concentration of copper nitrate, zinc nitrate, aluminum nitrate mixed solution, Cu: Zn: Al = 5: 3.5: 1.5 in the solution, co-precipitate with ammonium carbonate at 70 ° C, after washing, dry at 120 ° C , calcined at 400°C, and then added graphite flakes to make a cylindrical catalyst A with a diameter of φ4mm×5mm.

[0020] Get above-mentioned catalyzer and pack in the reaction tube of the reactor of the present invention, the stainless steel tube that reaction tube size is phi 25mm * 3mm * 1200mm. Before operation, treat it with hydrogen-nitrogen mixed gas with a hydrogen content of 0.5% for 1 hour, the pressure is 0.5MPa, and the vapor space velocity is 300h -1 . Then gradually raise the temperature to 250° C., and gradually increase the hydrogen content in the hydrogen-nitrogen mixture to 2% of the hydrogen content, until the hydrogen content at the outlet and inlet of the reactor is basically the same.

[0021] The reaction bed temperature was raised t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com